Suspension type monorail vehicle bogie and suspension type monorail train

A suspension type, monorail vehicle technology, applied in the field of rail vehicles, can solve problems such as the impact of the ride comfort of the whole vehicle, and achieve the effect of improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

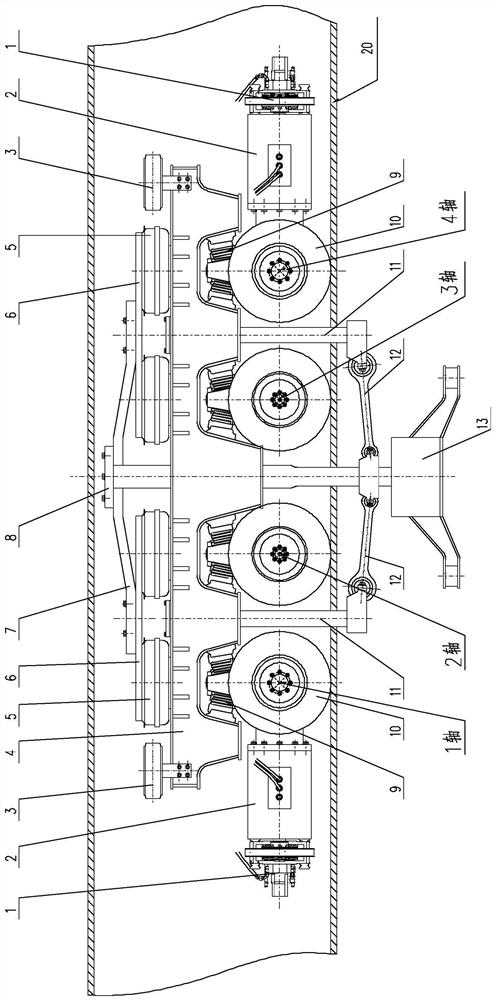

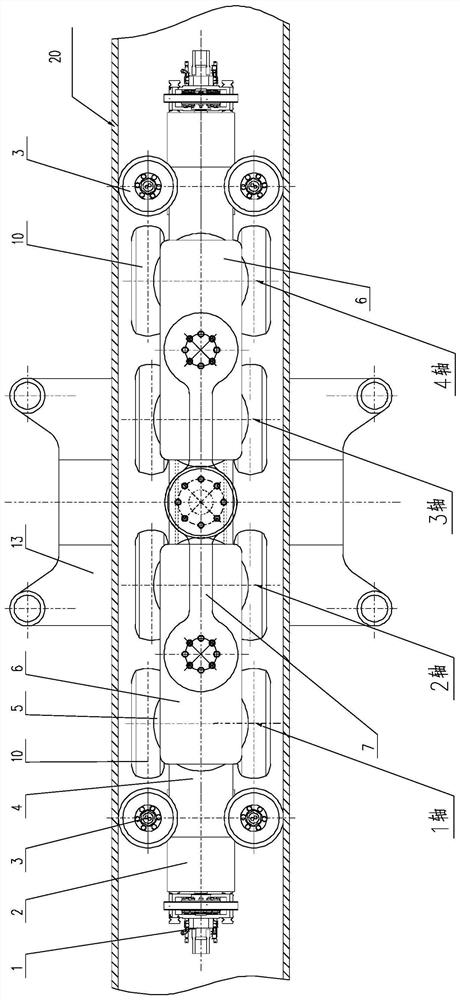

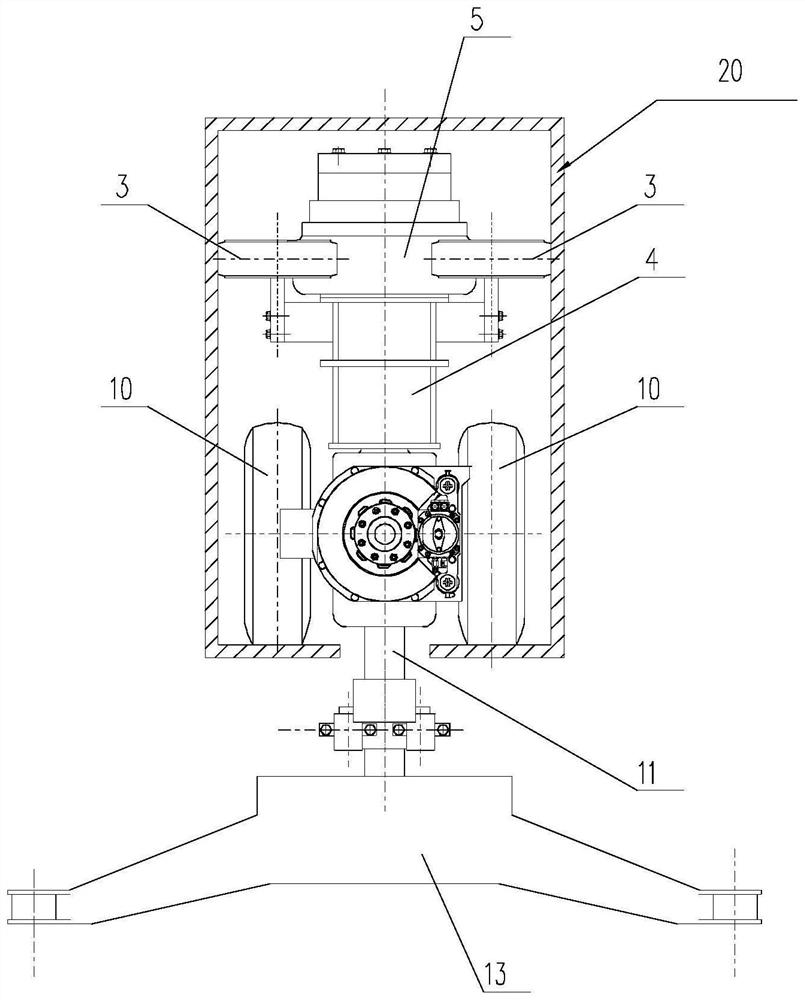

[0035] Such as Figure 1-Figure 3 As shown, the suspended monorail vehicle bogie of the present embodiment includes a frame 4 and a main drawbar 8 passing through the frame 4 vertically and two auxiliary drawbars 11, and two groups of wheel drive devices installed on the frame 4; The two groups of wheel drive devices are arranged symmetrically on both sides of the main drawbar 8 in the longitudinal direction.

[0036] Both ends of the frame 4 in the longitudinal direction are provided with guide wheel sets, which include two guide wheels 3 respectively arranged at both ends of the frame 4 in the transverse direction, and the guide wheels 3 are used to contact the corresponding side walls of the track beam 20 .

[0037] The wheel drive device includes a driving braking mechanism fixed on the frame 4, and a power shaft 17 and a non-power shaft 16 that are rotatably mounted on the frame 4, and the driving braking mechanism is connected with the power shaft 17 in transmission; the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap