Novel reinforced concrete drain pipe construction method and construction assembly

A technology of reinforced concrete and construction method, which is applied to the sewer system, waterway system, water supply device, etc., can solve the problems of leakage at the assembly connection, inaccurate installation accuracy, poor sealing performance, etc., and achieves high installation accuracy, achieve the effect of moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

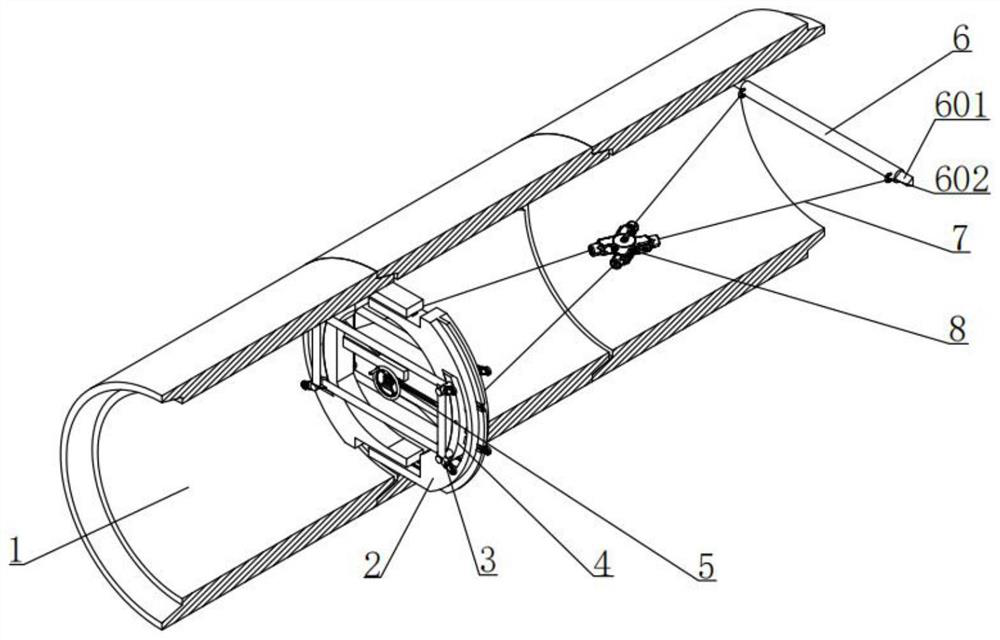

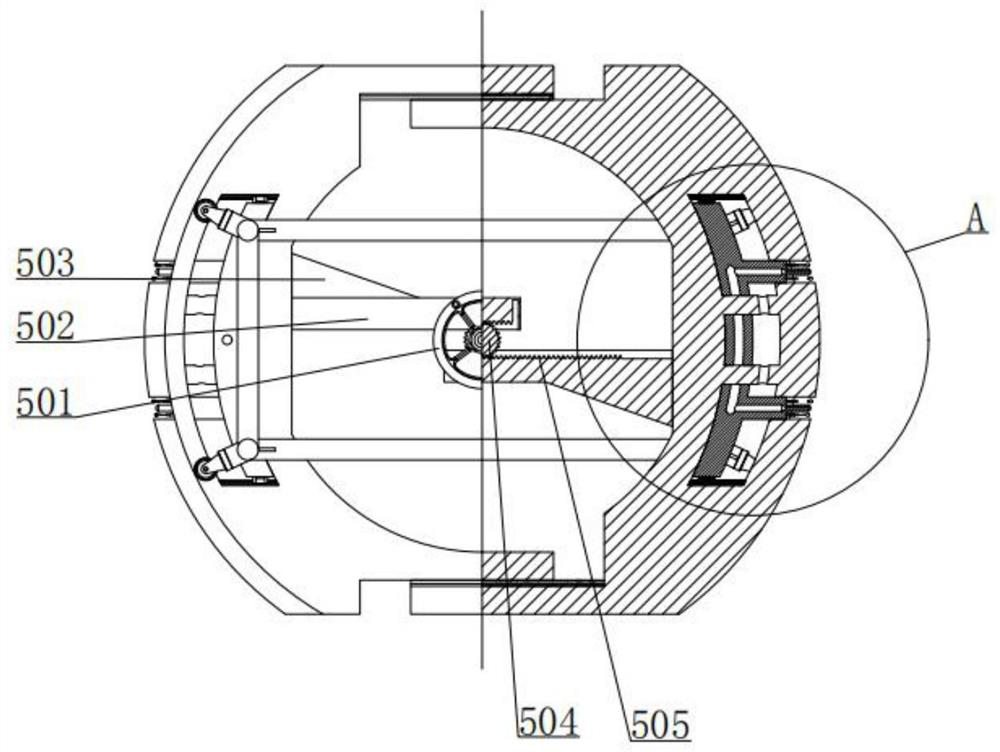

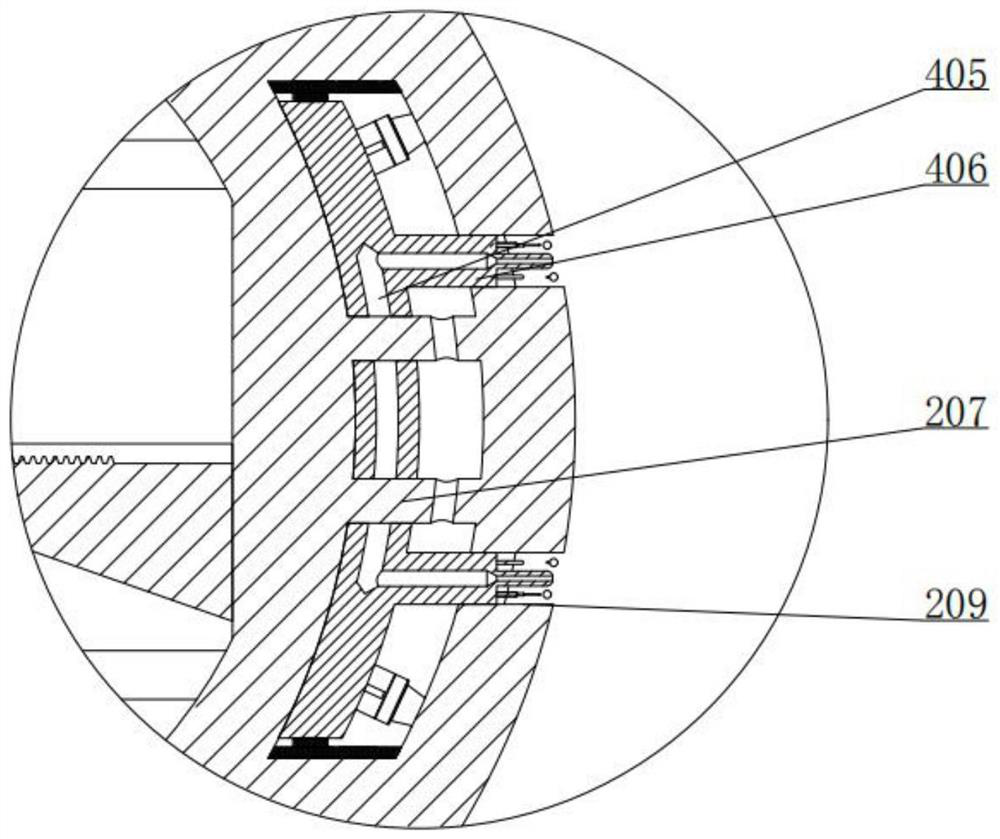

[0062] Such as Figure 1-7 Shown, the invention discloses the construction method of this novel reinforced concrete drainage pipe construction assembly, comprises the following steps:

[0063] S1, prepare in advance, place the assembly mechanism inside the tube body of multiple installation tubes 1, align the embedded snap ring 205 on the baffle part 2 with the matching groove 101 and the matching boss between two adjacent installation tubes 1 102 fit the gap formed, turn the hand wheel 501, stretch the two baffle bodies 201 until the embedded snap ring 205 is clamped in the gap between the two adjacent installation pipes 1, and fix the retaining column 6 on the installation pipe to be installed 1, the sealant delivery pipe is connected at the sealant inlet 403 of the injection part body 401 in the retaining column fixing groove 103;

[0064] S2, drain pipe assembly, turn the manual hoist 8 to tighten the wire rope 7, align the matching groove 101 at the head end of the insta...

Embodiment 2

[0080] This embodiment is as a further improvement of the previous embodiment, such as Figure 1-7 Shown, the invention discloses the construction method of this novel reinforced concrete drainage pipe construction assembly, comprises the following steps:

[0081] S1, prepare in advance, place the assembly mechanism inside the tube body of multiple installation tubes 1, align the embedded snap ring 205 on the baffle part 2 with the matching groove 101 and the matching boss between two adjacent installation tubes 1 102 fit the gap formed, turn the hand wheel 501, stretch the two baffle bodies 201 until the embedded snap ring 205 is clamped in the gap between the two adjacent installation pipes 1, and fix the retaining column 6 on the installation pipe to be installed 1, the sealant delivery pipe is connected at the sealant inlet 403 of the injection part body 401 in the retaining column fixing groove 103;

[0082] S2, drain pipe assembly, turn the manual hoist 8 to tighten the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap