Water well head master gate rush-spraying device

A technology for gates and water wells, which is applied in the field of spraying devices for the main gate of the wellhead, and can solve problems such as inability to disassemble the main gate, environmental pollution, and stratum blowout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The detailed description and technical content of the present invention are described as follows in conjunction with the accompanying drawings. However, the accompanying drawings are only provided for reference and description, and are not used to limit the present invention.

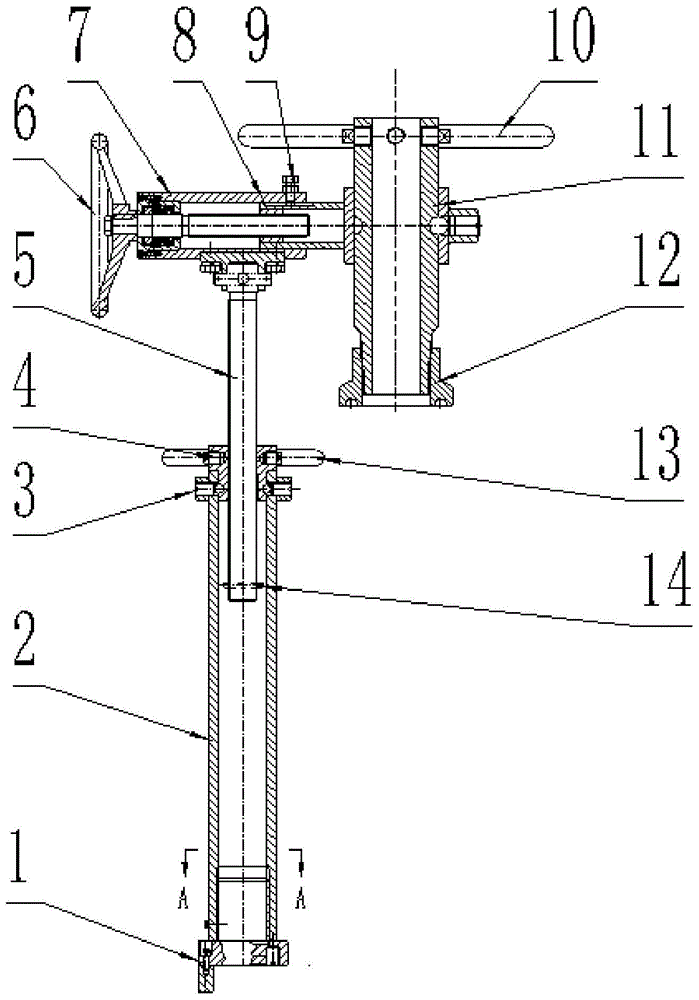

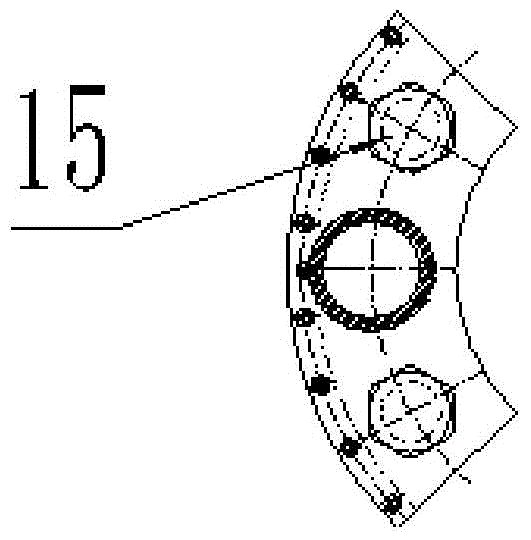

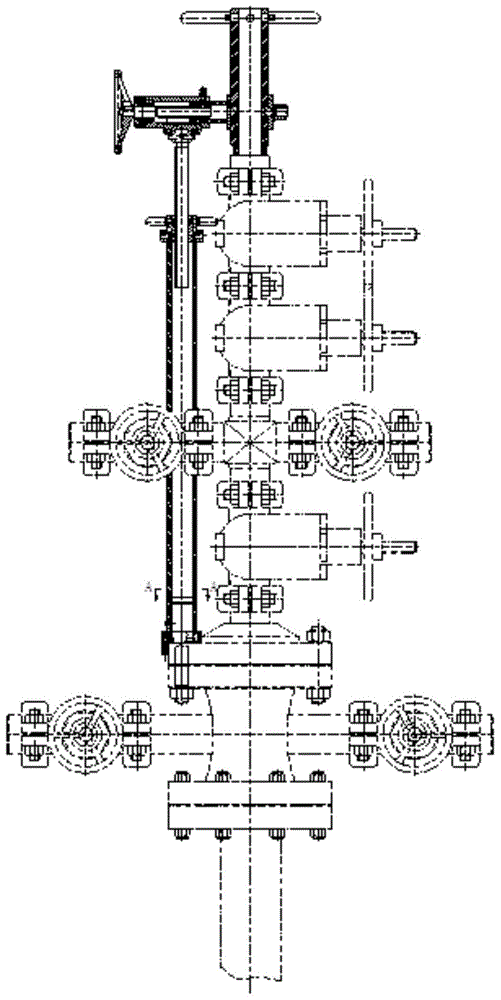

[0021] Reference attached Figure 1-4 , A blowout device for the main gate of a water well, comprising a rotating sub-joint 11, a connecting clamp 12, a horizontal adjustment device, and a vertical adjustment device, the horizontal adjustment device being connected to the top end of the vertical adjustment device, the rotating sub-section 11 is arranged at the lateral moving end of the horizontal adjustment device, the connecting clamp 12 is connected to the bottom end of the rotating sub, and the bottom end of the vertical adjustment device is provided with a mounting seat 1. The mounting base is fan-shaped, and a screw hole for mounting the bolt 15 is opened on the top.

[0022] A handle 10 is inst...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap