Bead embroidery bead discharging structure capable of automatically supplementing material and bead embroidery machine

A feeding and automatic technology, which is applied in the field of embroidery machinery, can solve the problems of not being able to attract beads smoothly, jumping out, etc., and achieve the effect of avoiding too many beads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

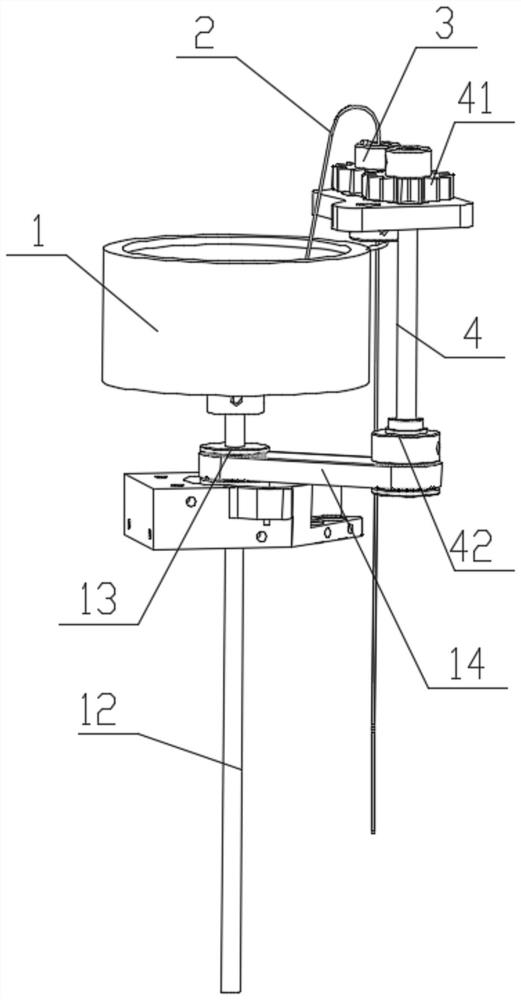

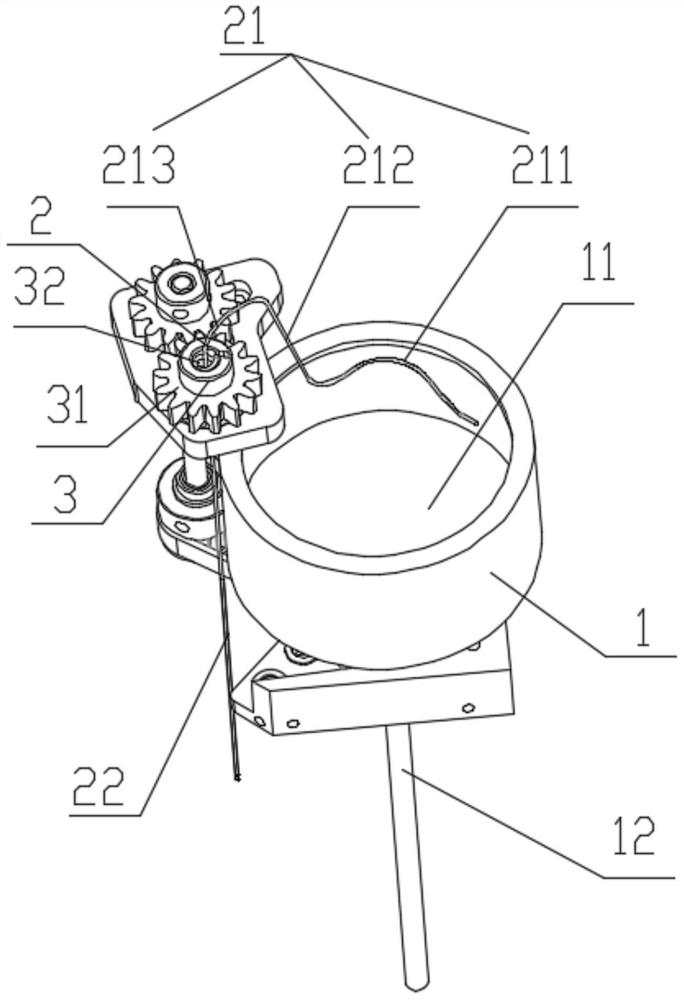

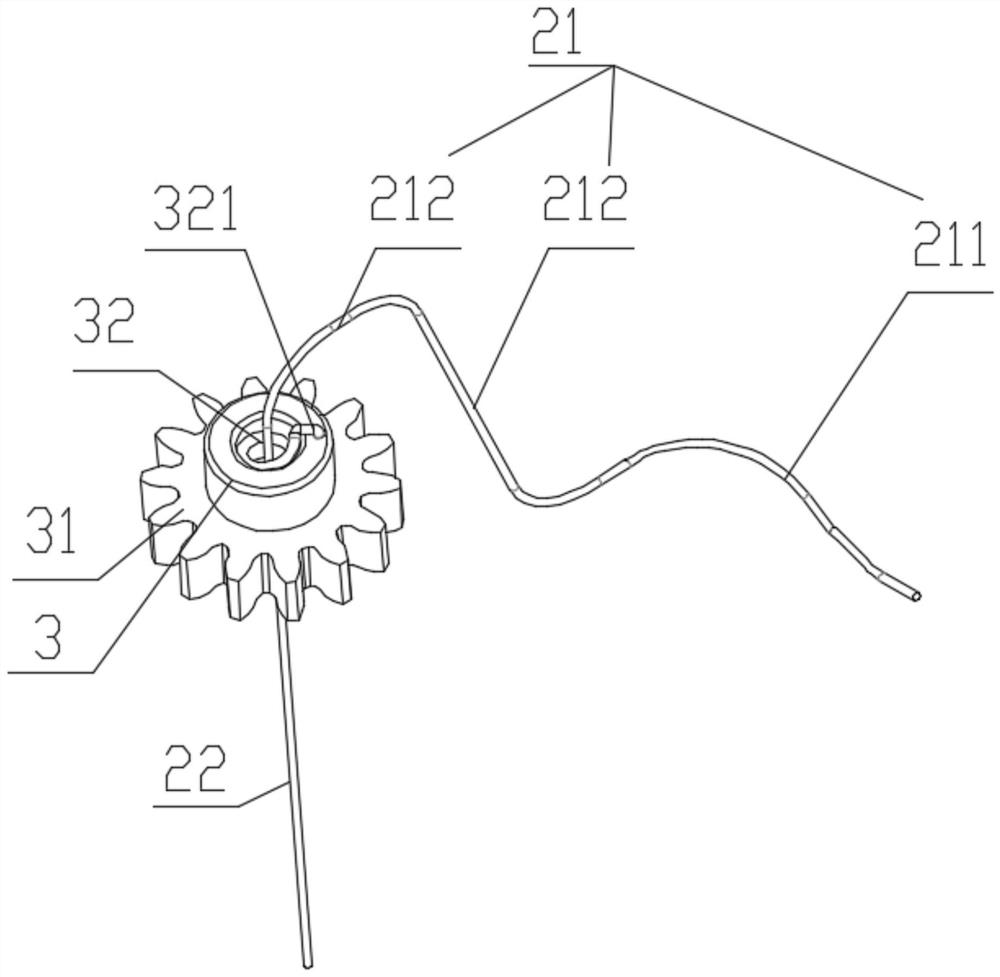

[0038] refer to Figure 1 to Figure 9 As shown, a beading beading structure for automatic feeding, including a beading steel wire 2 connected to a memory 1 for storing beads, the bottom of the memory 1 is connected to a turntable 11, and the beading steel wire 2 is connected to the bottom of the memory 1 Including a bead segment 21 and a lower bead segment 22, the head end of the bead segment 21 extends into the storage device 1 from top to bottom, the lower bead segment 22 extends from top to bottom and the upper end is connected to the tail of the bead segment 21 connected end to end. The rotation of the turntable 11 promotes the beads in the memory 1 to penetrate into the head end of the bead segment 21 and arrange them in series.

[0039] In order to automatically refill in time when there are few beads in the storage 1, a refilling device is also provided. like Figure 4 to Figure 9 As shown, the feeding device includes a feeding container 100 arranged above the storag...

Embodiment 2

[0056] The bead embroidery machine includes the bead embroidery bead structure with automatic feeding as described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com