Intelligent pressure relief valve and using method

A release valve, intelligent technology, applied in the direction of functional valve type, safety valve, balance valve, etc., can solve problems such as non-action, pressure relief valve can not protect the transformer operation well, mechanical parts response delay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

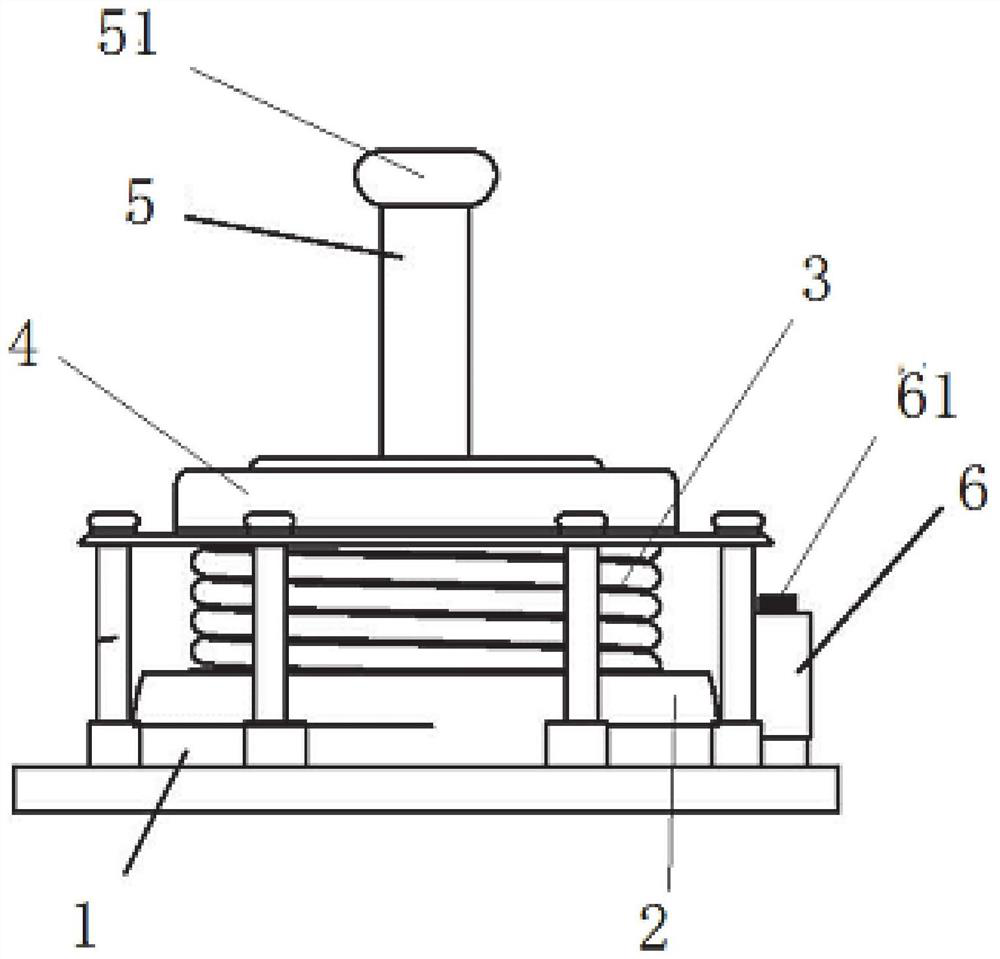

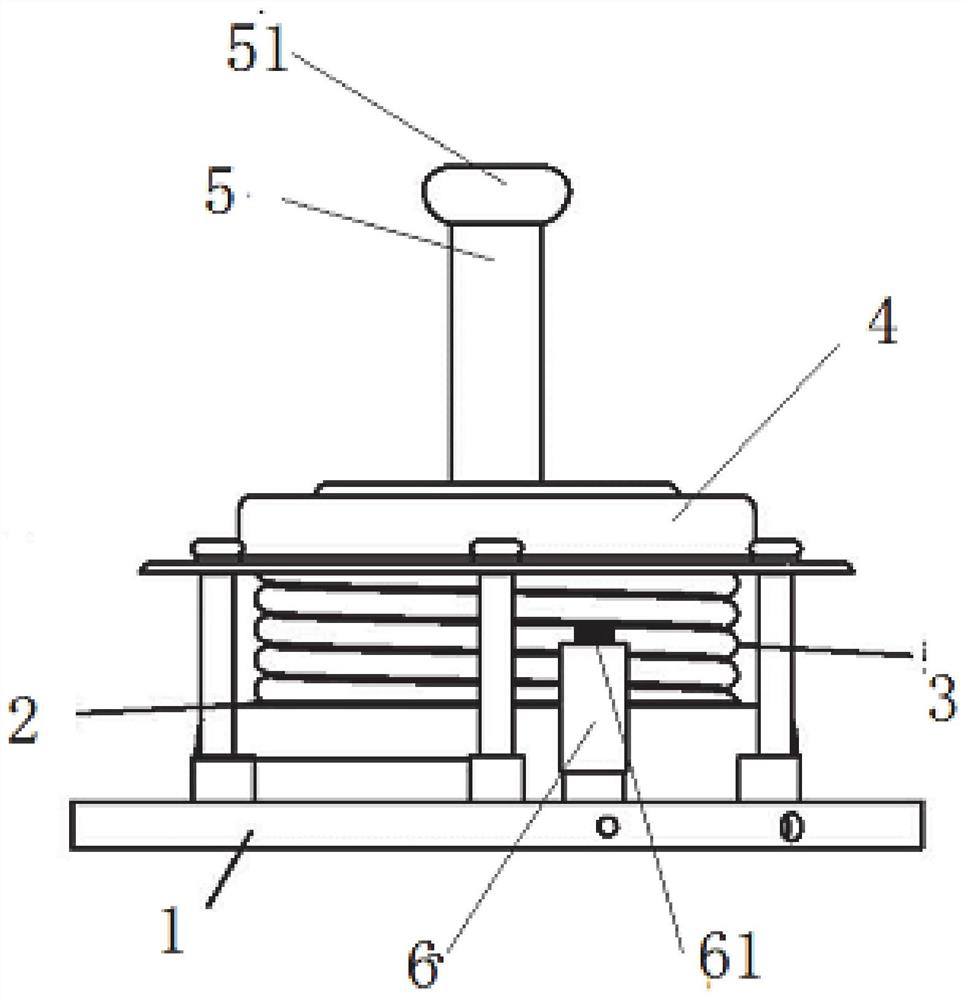

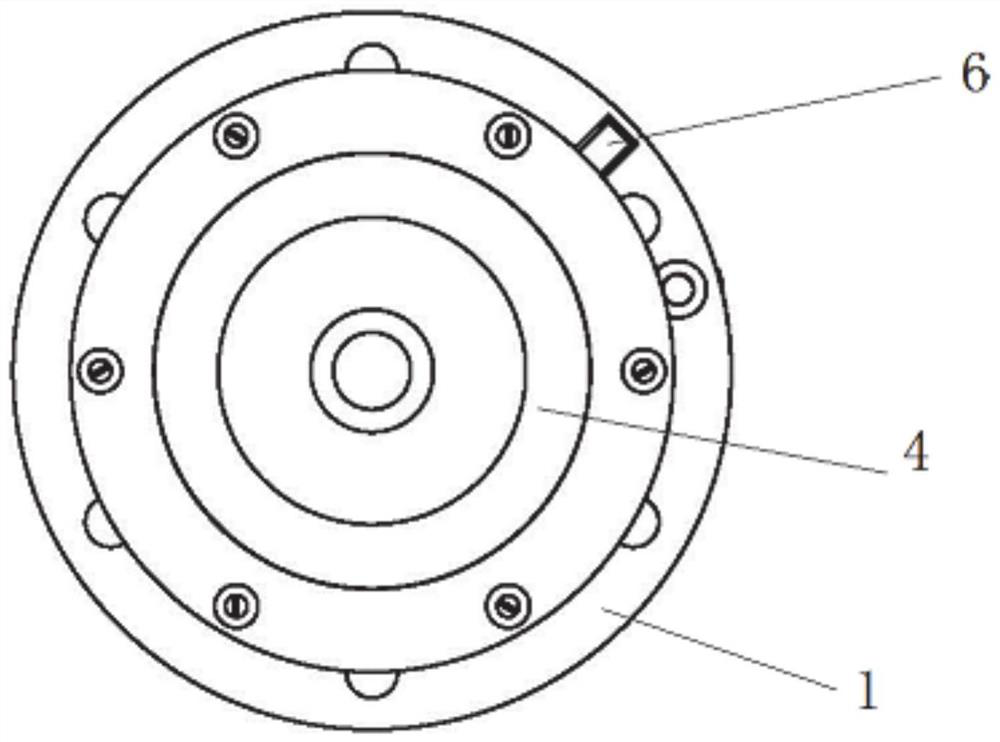

[0030] Such as Figure 1-3 As shown, an intelligent pressure relief valve includes a valve seat 1 communicated with the transformer oil tank, an external casing of the valve seat 1, a valve cover on the top of the casing, and a pressure relief port on the casing;

[0031] The valve seat 1 is connected to the spring seat 4 through a fastener, and the direction of the spring seat 4 close to the valve seat 1 is connected to the actuating disk 2 through the spring 5, and the actuating disk 2 is closely attached to the valve seat 1.

[0032] The valve seat 1 has a hollow pressure sensing section 6 . One end of the pressure sensing section 6 has a pressure sensing port 61 , and the other end is connected to the valve seat 1 . The pressure transmitter is connected to the valve seat 1 through the pressure sensing port 61 .

[0033] The pressure transmitter communicates with the transformer oil tank through the pressure taking port 61, the pressure taking section 6 and the valve seat 1...

Embodiment 2

[0043] Here's how to use the above pressure relief valve:

[0044] When the transformer is running, the valve seat 1 communicates with the inside of the transformer oil tank, and the action disc 2 driven by the spring 5 presses the valve seat 1 to seal the transformer oil. When an accident occurs inside the transformer, the oil pressure inside the transformer oil tank rises, and when the pressure limited by the transformer oil to the sealing gasket is greater than the pressure of the spring 5, the actuating disc 2 starts to move upward, separating the actuating disc 2 from the valve seat 1, and then opens The pressure relief valve releases the pressure, and at the same time, the pop-up action plate 2 drives the flag rod 5 to be lifted up, and then drives the flag cap 51 to jack up, indicating that the pressure relief valve is in an open state at this time.

[0045]The transformer oil leaks, and the pressure in the transformer oil tank drops. When the pressure drops to the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com