A nuclear industry equipment disassembly robot and quick disassembly method

A nuclear industry and robot technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of inability to disassemble and assemble the whole machine, and achieve the effect of fast disassembly and assembly, good safety, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

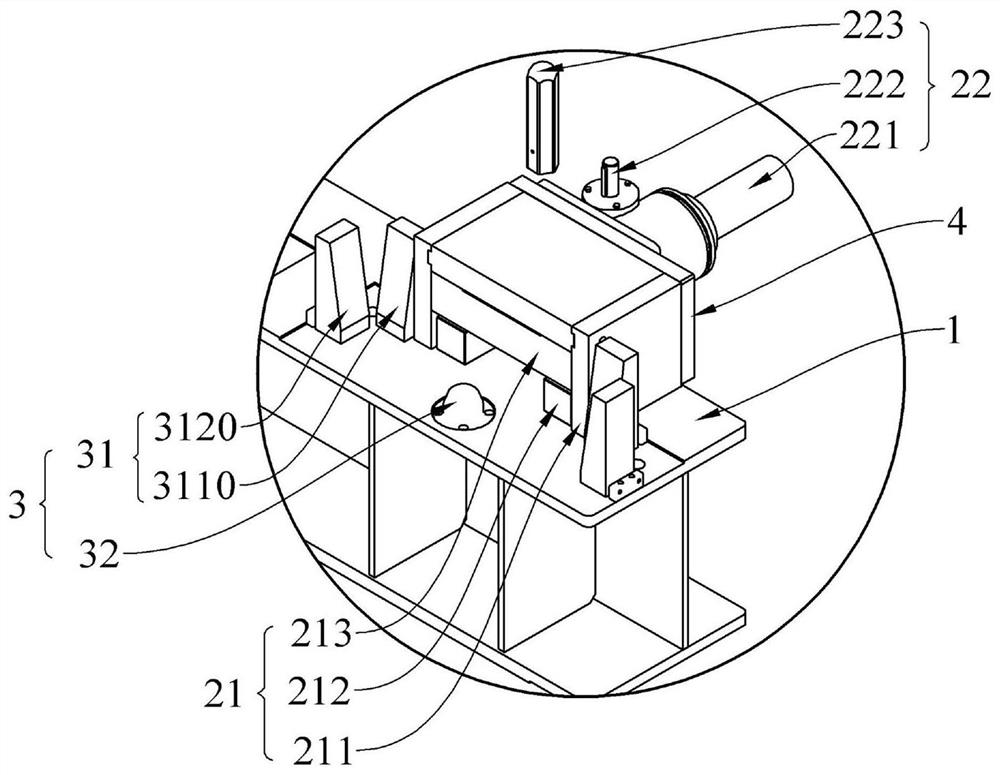

[0036] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. Among them, the orientation nouns such as "up", "down", "left" and "right" mentioned in this article are preceded by figure 1 orientation as a reference.

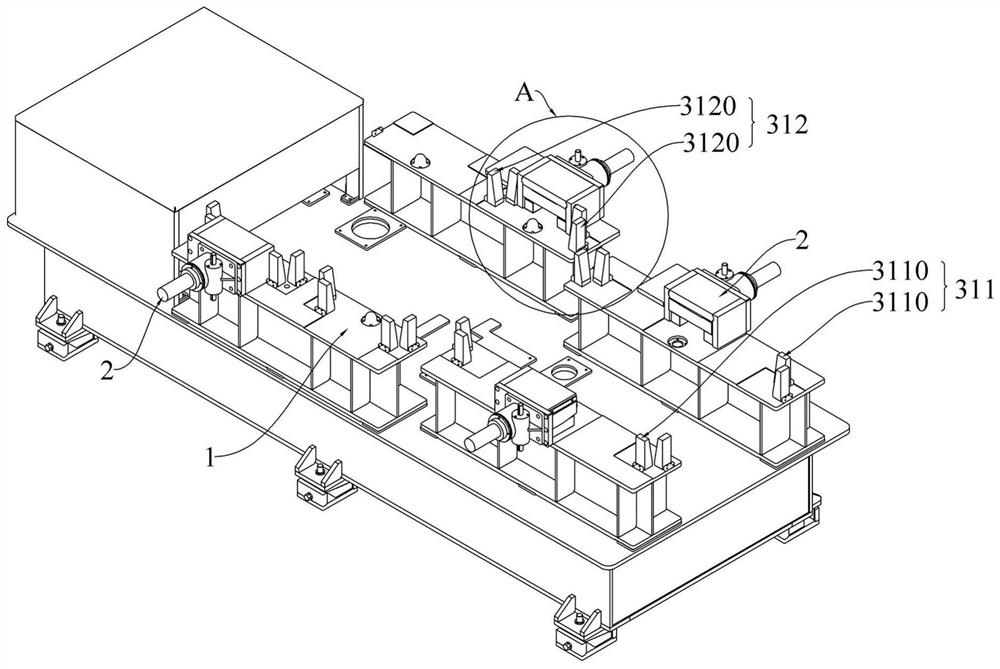

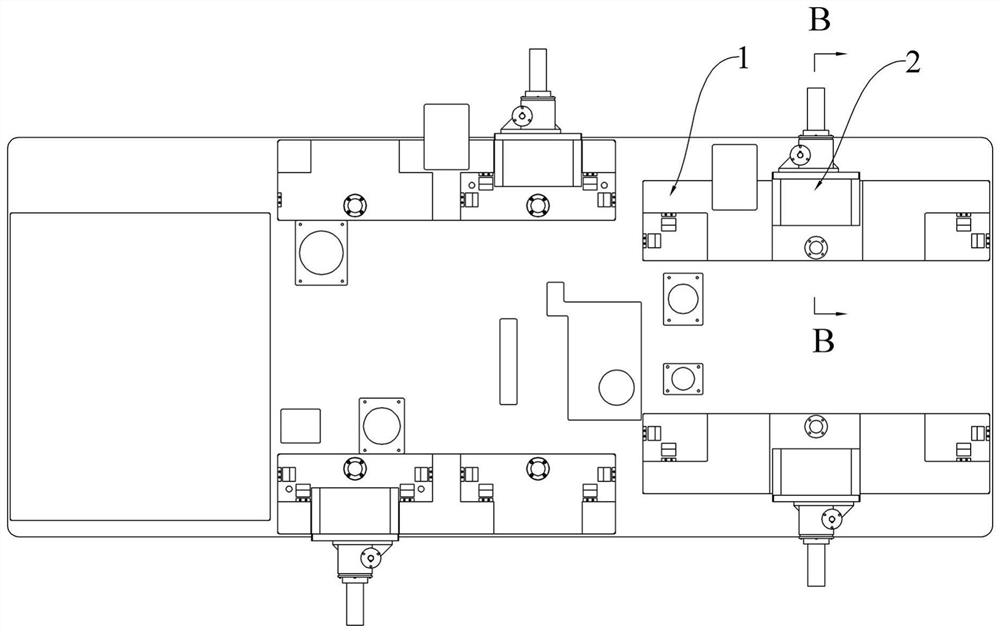

[0037] see figure 1 with figure 2 , the present invention provides a nuclear industry equipment disassembly robot, which includes a workbench 1, a manipulator (not shown) all arranged on the workbench 1, a plurality of disassembly structures 2, a plurality of positioning components 3, displacement sensors ( not shown) and a controller (not shown).

[0038] Specifically, the positioning assembly 3 includes a plurality of guide piles 31 and a plurality of positioning pins 32 respectively arranged on the workbench 1. The plurality of guide piles 31 are distributed at intervals around nuclear industrial equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com