Light-absorbing layer and joined body provided with light-absorbing layer

A light-absorbing layer and junction technology, which is applied in the field of junctions, can solve problems such as output reduction, achieve the effects of suppressing manufacturing costs and preventing parasitic oscillations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

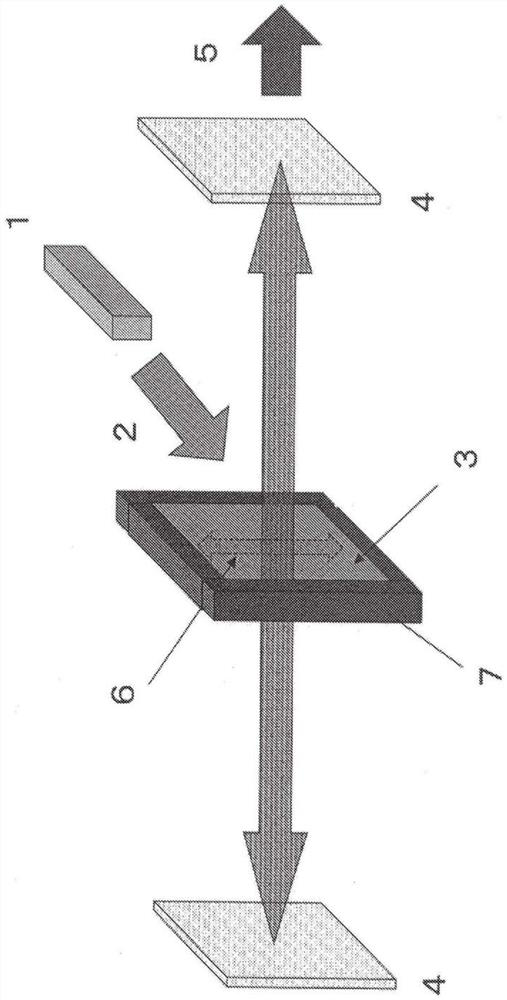

Method used

Image

Examples

Embodiment

[0044] Hereinafter, it demonstrates based on an Example and a comparative example. It should be noted that this embodiment is only an example and is not limited by this example. That is, the present invention is limited only by the claims, and includes various modifications other than the examples included in the present invention.

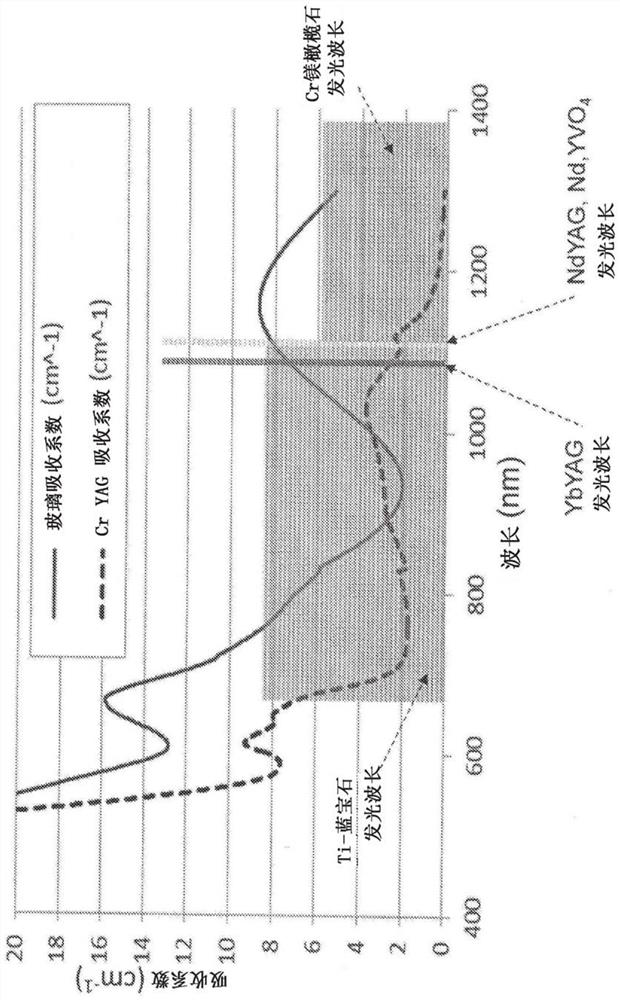

[0045] For reference, the characteristics of conventional Cr:YAG (cladding) are shown below. Cr:YAG has a melting point of 1970°C and an absorption coefficient of 3.5cm -1 (Wavelength: 650nm~1400nm), the refractive index is 1.82, and the thermal expansion rate is 7.8ppm / K. Furthermore, in the case of using Nd:YAG as a laser medium (refractive index: 1.82, thermal expansion coefficient: 8 ppm / K), the difference in refractive index is less than 0.01, and the difference in thermal expansion coefficient is almost zero.

[0046] (Example)

[0047] Titanium oxide, silicon oxide, sodium carbonate, and nickel oxide, which are raw materials for the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com