A snap-on assembly welding tool and assembly method

A buckle-type, welding tool technology, applied in the direction of manufacturing tools, welding equipment, non-electric welding equipment, etc., can solve the problems of low precision, low installation efficiency of static shoulders, etc., and achieve the effect of efficient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

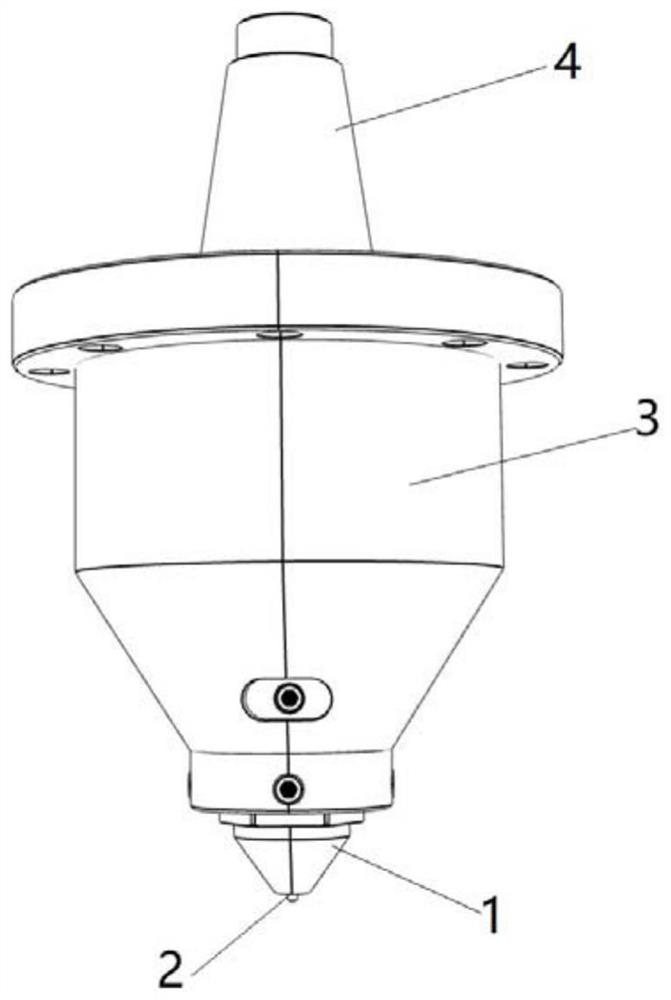

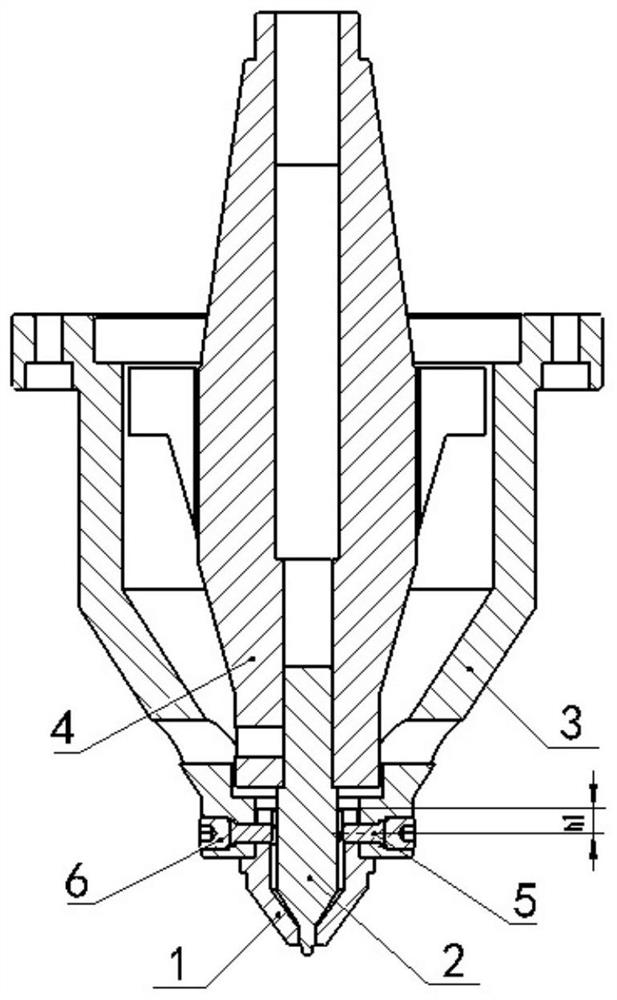

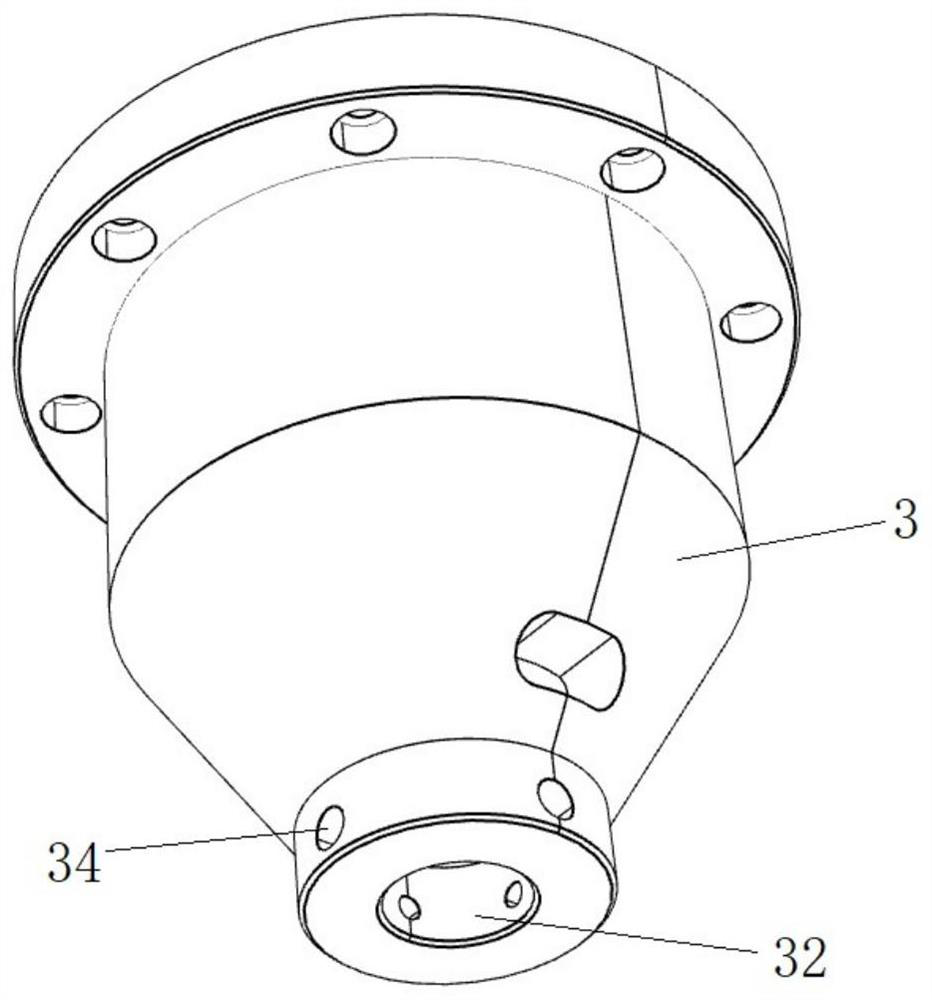

[0042] like Figure 1-8 As shown, the present embodiment provides a snap-fit welding tool, which includes a stationary shaft shoulder 1, the top end of the stationary shaft shoulder has a positioning ring 12, and the bottom end has a welding surface 15; There are at least two bending slots 11, such as Figure 5As shown, the number of the bending slots 11 is four, and they are evenly arranged around the positioning ring 12; wherein, preferably, the bending slots include a vertically arranged first slot and an obliquely arranged second slot. The first slot and the second slot are communicated; the above-mentioned welding tool also includes a shoulder flange 3 and a stirring needle 2 arranged coaxially with the stationary shaft shoulder 1, and the bottom end of the shoulder flange 3 has an accommodating The positioning hole 32 of the positioning ring 12 has a clamping member in the positioning hole 32 that is adapted to the bending and clamping groove 11 . The snap-on assembl...

Embodiment 2

[0058] This embodiment provides a friction stir welding device, which includes a motor, a rotating spindle, and a welding tool, and the welding tool is the snap-on assembly welding tool described in Embodiment 1. It adopts the snap-type structure to realize the clamping and dismounting of the stationary shaft shoulder. There is no need to install and remove the nut when assembling the axle shoulder, and the efficiency is high; Coaxial connection of shoulder flanges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com