A new type of bottom stamping equipment for the manufacture of new ceramic products

A new product, ceramic technology, applied in printing, stamping and other directions, can solve the problems of easy to overturn ceramics, slow ceramic stamping speed and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

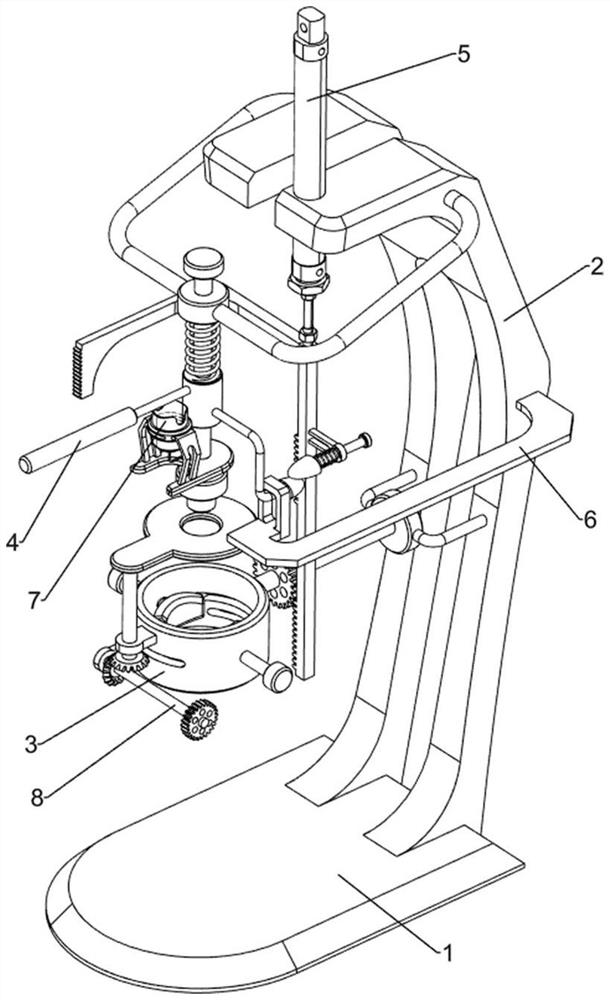

[0030] A new type of bottom stamping equipment for the manufacture of new ceramic products, such as figure 1 As shown, it includes a bottom plate 1, a support frame 2, a clamping mechanism 3 and a manual stamping mechanism 4. The upper right side of the bottom plate 1 is provided with a supporting frame 2, the supporting frame 2 is provided with a clamping mechanism 3, and the supporting frame 2 is provided with a supporting frame 2 on the right side. There is a manual stamping mechanism 4 .

[0031] When the user needs to stamp the ceramic bottom, the device can be used. First, the ceramic to be stamped is placed in the clamping mechanism 3 for fixing, and then the ceramic bottom is stamped by the manual stamping mechanism 4. After the printing is completed, the ceramics in the clamping mechanism 3 can be taken out.

Embodiment 2

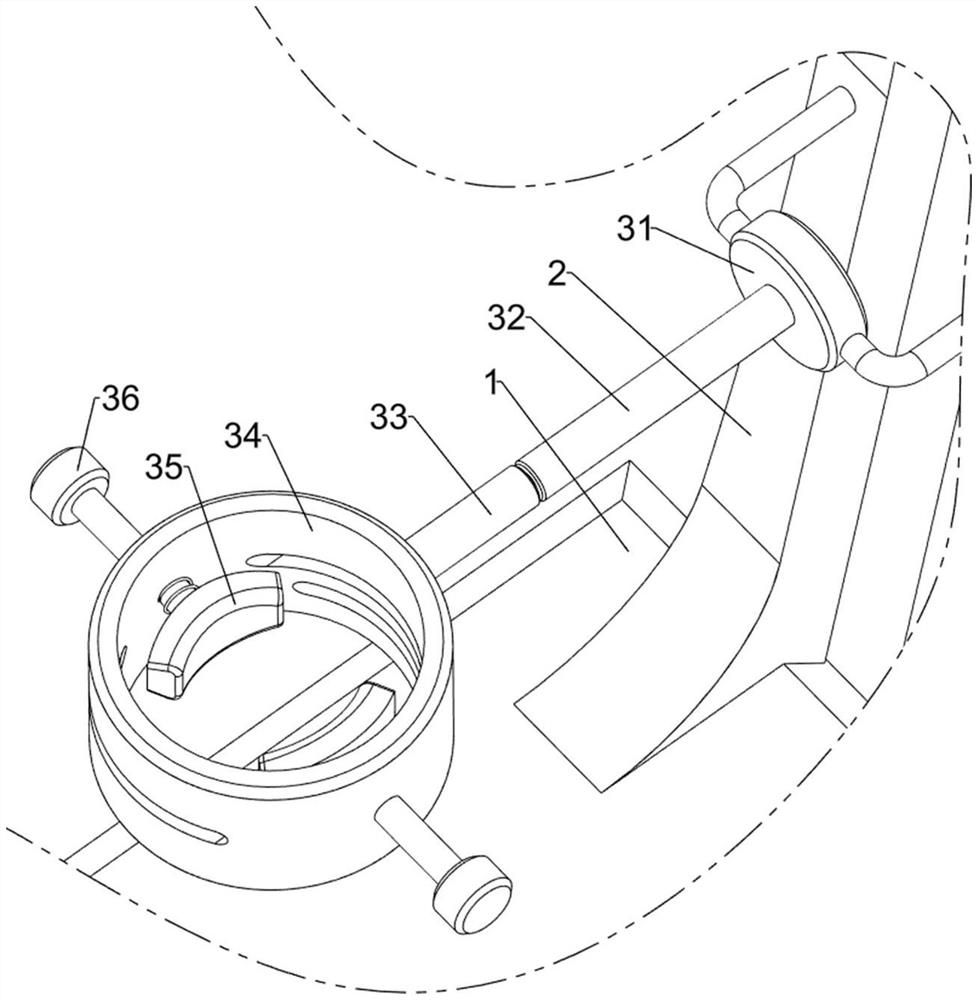

[0033] On the basis of Example 1, as Figure 2-4 As shown, the clamping mechanism 3 includes a first fixing column 31, a connecting rod 32, a first rotating shaft 33, a fixing frame 34, a splint 35 and a first telescopic group 36, and a first fixing column 31 is provided in the middle of the left side of the support frame 2 , a connecting rod 32 is provided on the left side of the first fixing column 31, a first rotating shaft 33 is rotatably provided on the connecting rod 32, a fixed frame 34 is connected on the left side of the first rotating shaft 33, and the fixed frame 34 is symmetrically slid back and forth with a first rotating shaft 33. Both the telescopic group 36 and the inner side of the first telescopic group 36 are provided with a splint 35 .

[0034] The user can manually pull the first telescopic group 36 and the splint 35 on both sides, so that the first telescopic group 36 is compressed, and then the user places the ceramics that need to be stamped in the fixe...

Embodiment 3

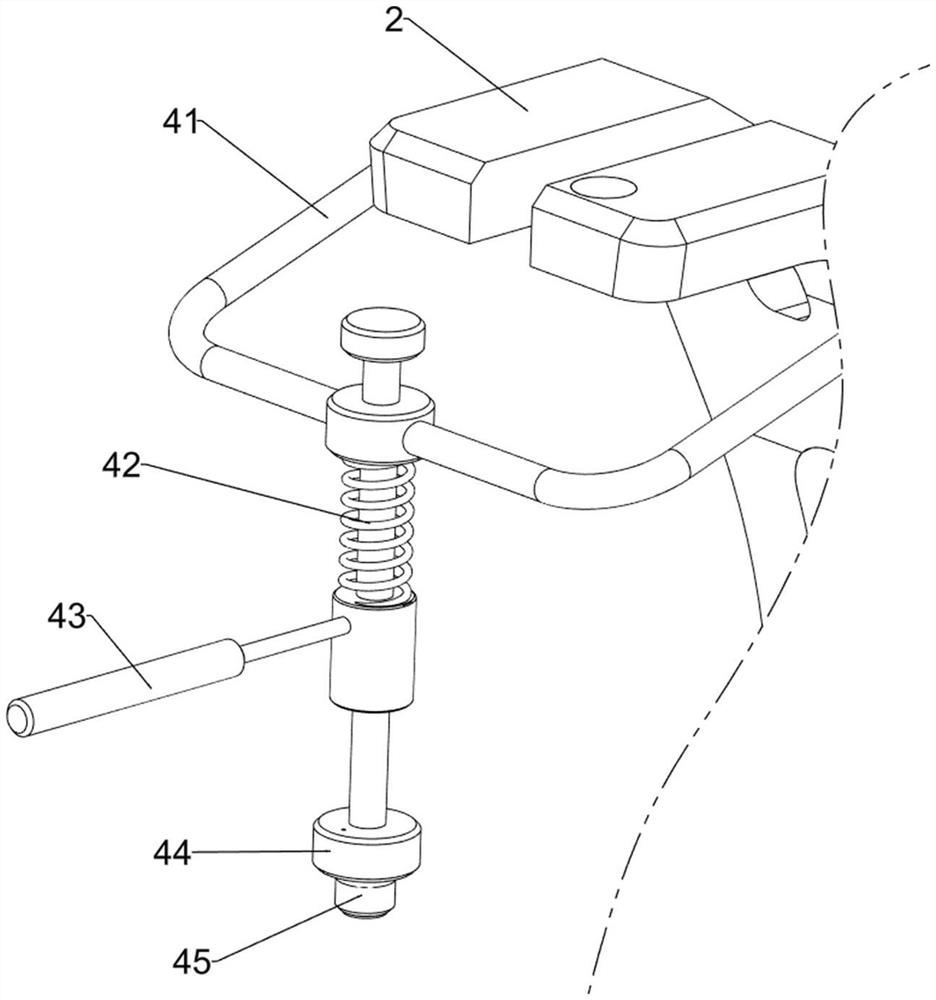

[0038] On the basis of Example 2, as Figure 5-10 As shown, it also includes an overturning mechanism 5, the overturning mechanism 5 includes a cylinder 51, a first rack 52 and a first gear 53, the top of the support frame 2 is provided with a cylinder 51, and the cylinder 51 is connected with a first rack 52, A rotating shaft 33 is provided with a first gear 53 , and the first rack 52 is engaged with the first gear 53 .

[0039] The user opens the air cylinder 51, the air cylinder 51 drives the first rack 52 to move downward, and the first rack 52 engages with the first gear 53, so that the first gear 53 and the first rotating shaft 33 rotate half a circle, thereby making The ceramic rotates for half a turn. When the middle part of the first rack 52 moves to the position of the first gear 53, the first rack 52 no longer engages with the first gear 53. At this time, the ceramic bottom stamping is completed. When the rack 52 moves downward and continues to mesh with the first ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com