Optical filter dust removal device for intelligent manufacturing

A technology of dust removal device and intelligent manufacturing, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of dust residue, labor-intensive, unclean cleaning, etc., and achieve the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

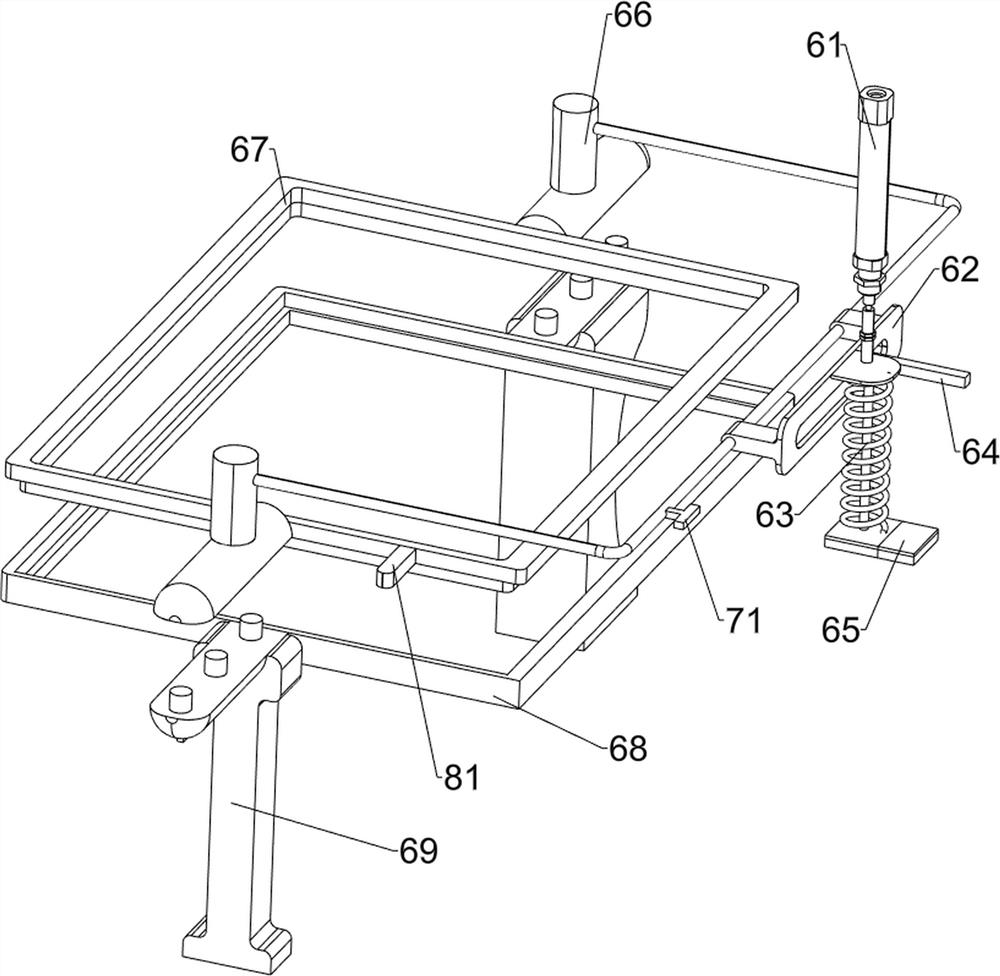

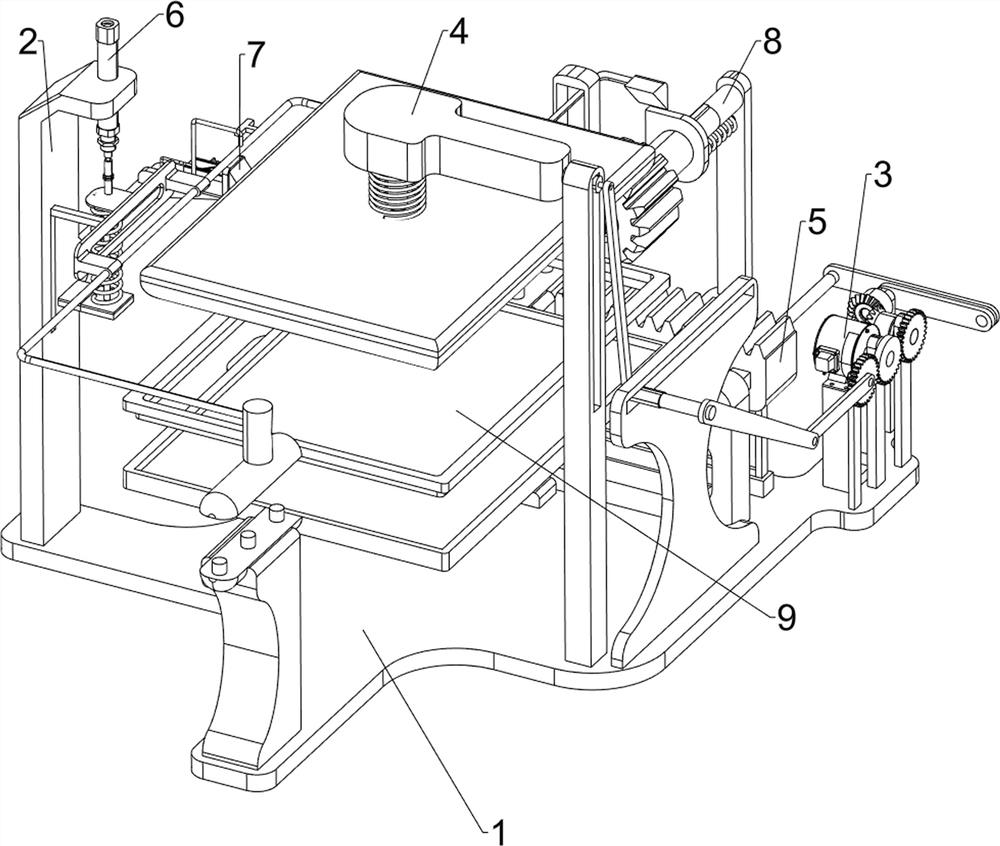

[0071] A filter dust removal device for intelligent manufacturing, such as figure 1 As shown, it includes a base plate 1, a first support frame 2, a driving mechanism 3 and a dust removal mechanism 4. The first support frame 2 is provided on the left side of the top of the base plate 1, and the drive mechanism 3 is provided on the right rear side of the top of the base plate 1. The top of the base plate 1 The right side is provided with dust removal mechanism 4.

[0072] Such as figure 2 As shown, the driving mechanism 3 includes a fixed seat 31, a motor 32, a sector gear 33, a first gear 34, a second support frame 35 and a transmission rod 36, and the right rear side of the top of the bottom plate 1 is provided with a fixed seat 31, and the top of the fixed seat 31 A motor 32 is provided, and a second support frame 35 is provided on the right rear side of the top of the base plate 1. A sector gear 33 is rotatably arranged on the second support frame 35. The drive shaft of t...

Embodiment 2

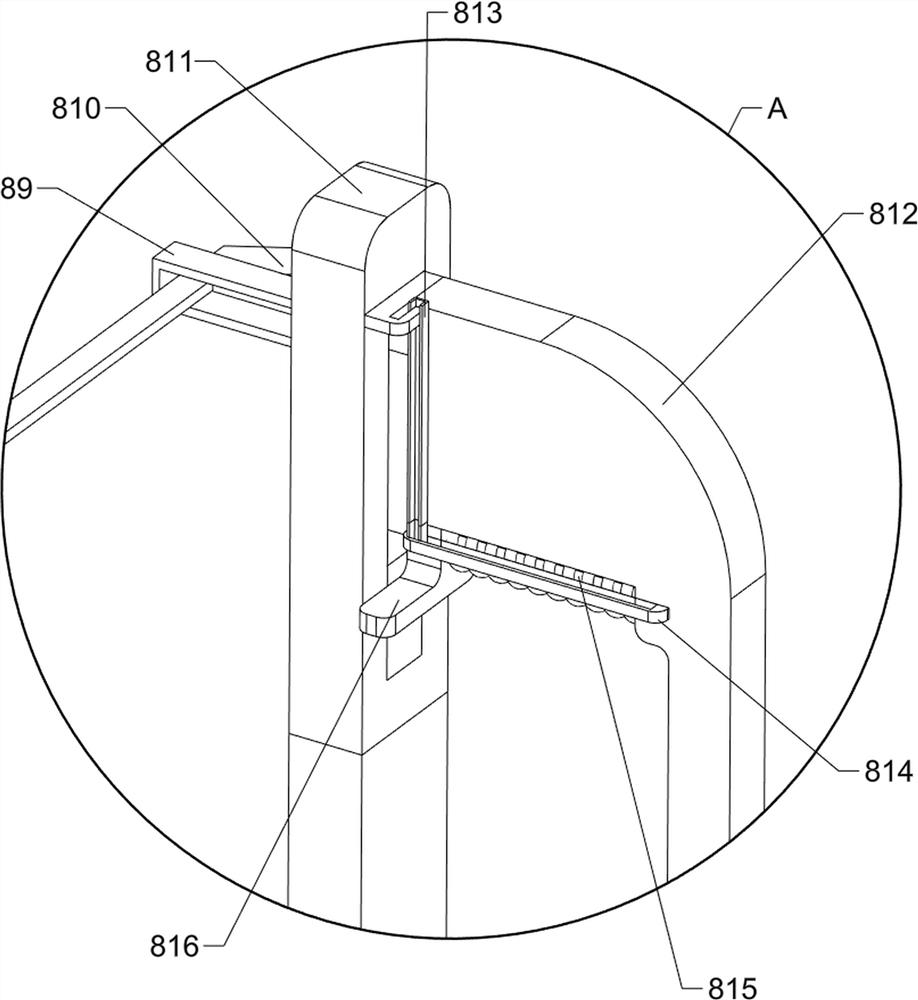

[0076] On the basis of Example 1, such as Figure 4 As shown, a propulsion mechanism 5 is also included, and the propulsion mechanism 5 includes a first fixed frame 51, a second gear 52, a bevel gear set 53, a crank connecting rod set 54, a transmission connecting rod 55, a rack 56, a third opening Slotted sliding frame 57, support bar 510 and first slotted sliding bar 511, base plate 1 top right rear side is provided with two first fixed frames 51, and the first fixed frame 51 on the front side is provided with the second gear 52 in rotation, A bevel gear set 53 is rotatably connected between the transmission shaft of the second gear 52 and the first fixed frame 51 on the rear side. The right side of the top of the base plate 1 is provided with a first slotted slide bar 511, which slides on the first slotted slide bar 511. A support rod 510 is arranged in the formula, a third slotted sliding frame 57 is provided on the right side of the bottom plate 1 top, a rack 56 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com