Bearing dismounting mechanism

A bearing and sliding machine technology, applied in the field of bearings, can solve problems such as the influence of the internal performance of the bearing, the quality affecting the use of the bearing, and the secondary damage of the bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

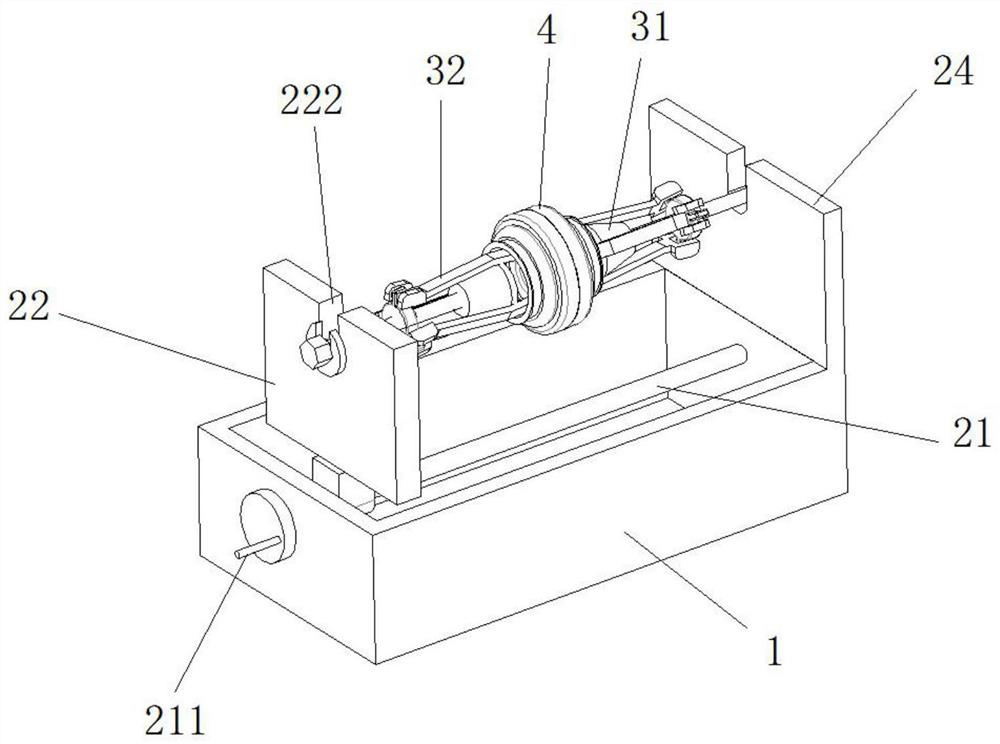

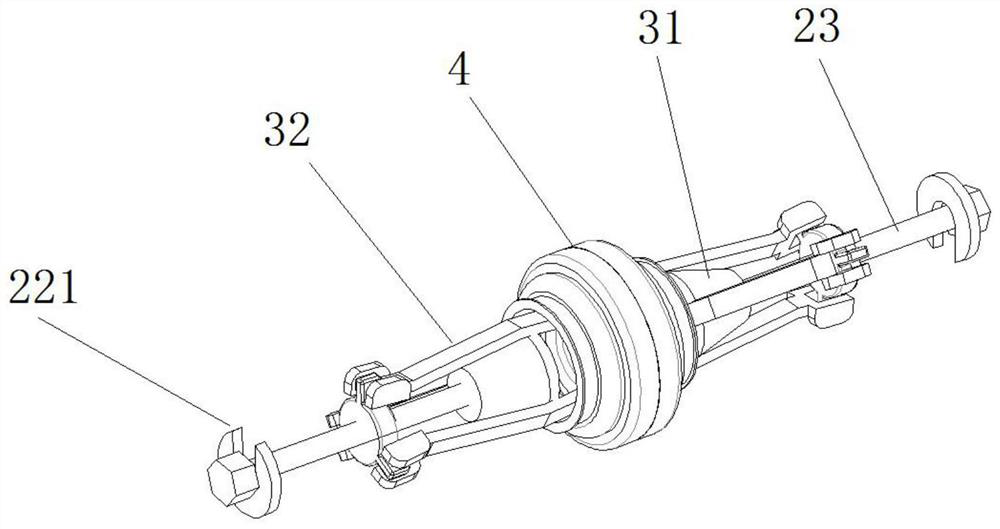

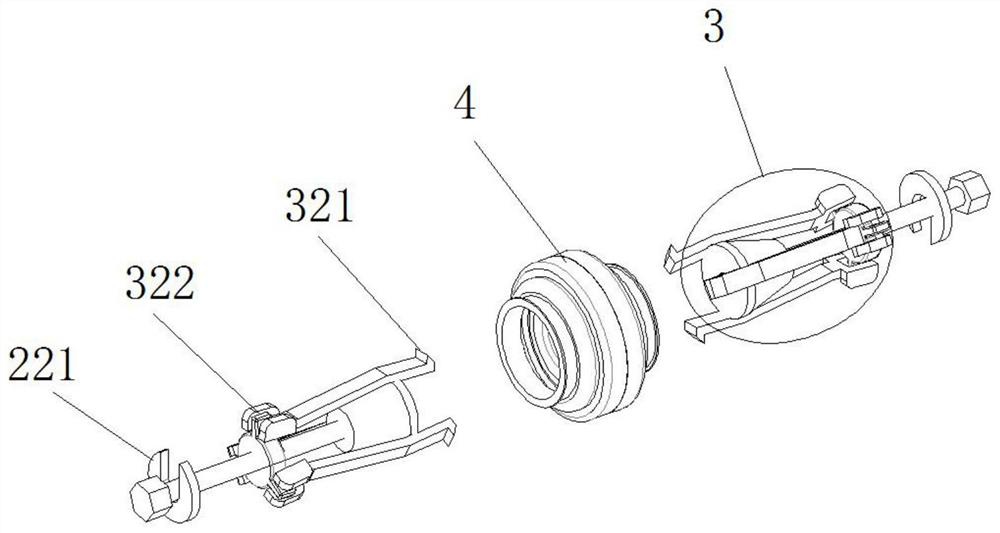

[0028] Depend on Figure 1 to Figure 8 It can be seen that the present invention discloses a bearing removal mechanism, which includes a lead screw sliding frame 1, a lead screw sliding assembly 2, and a pull code removal assembly 3. The lead screw set on the lead screw sliding frame 1 The sliding assembly 2, the screw sliding assembly 2 includes a rotating screw 21, a screw handle 211, an adjustment slide 22, a slide gasket 211, a U-shaped groove 222 of the slide, a beam 23, and a side fixing plate 24. The left side of the rotating screw 21 is fixedly connected with the screw handle 211, the outer surface screw of the rotating screw 21 is connected with the adjusting slide 22, and the upper outer surface of the adjusting slide 22 The U-shaped groove 222 of the sliding table is opened, the outer surface of the U-shaped groove 222 of the sliding table is provided with the gasket 211 of the sliding table, and the crossbeam 23 is placed in the groove of the U-shaped groove 222 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com