Electric vehicle damping mechanism

A shock absorbing mechanism, a technology for electric vehicles, applied in shock absorbers, engine components, engine lubrication, etc., can solve problems such as difficult replacement, inability to achieve shock absorption, and achieve the effect of avoiding difficult replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]In order to make the techniques, creative features, the purpose and efficacy of the present invention, and the embodiments are further illustrated below, but the invention is further illustrated, but the following examples are merely preferred embodiments of the invention, not all. Based on the embodiments in the embodiment, those skilled in the art will belong to the scope of the invention without making creative labor. The experimental method in the following examples, as not particularly illustrative, all of which are conventional methods, materials, reagents, etc. used in the following examples, such as non-special descriptions, can be obtained from the business pathway.

[0023]Embodiment:

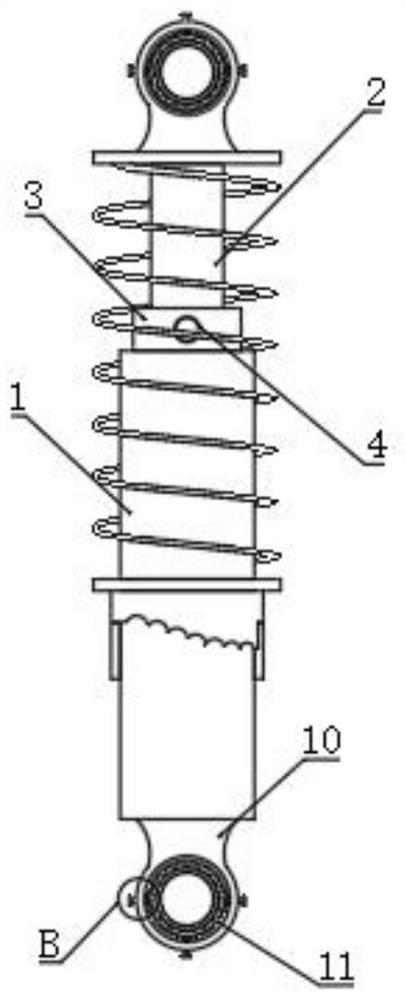

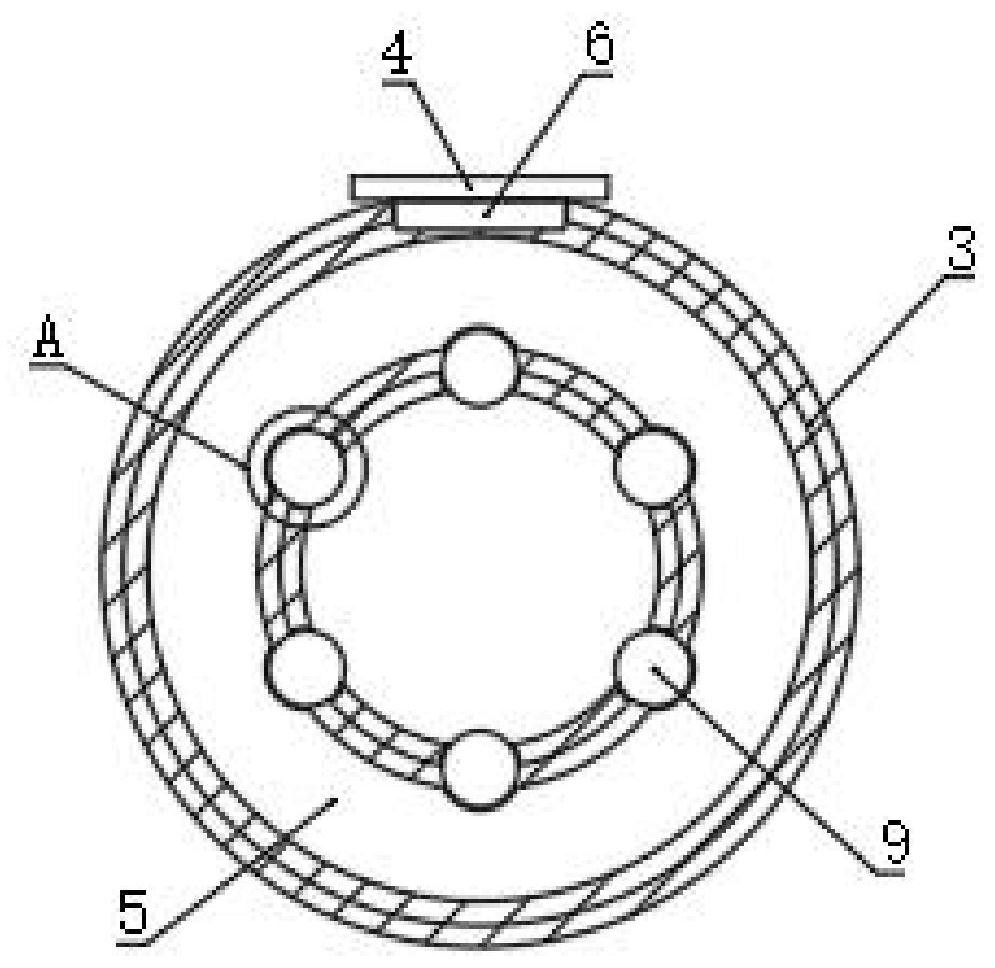

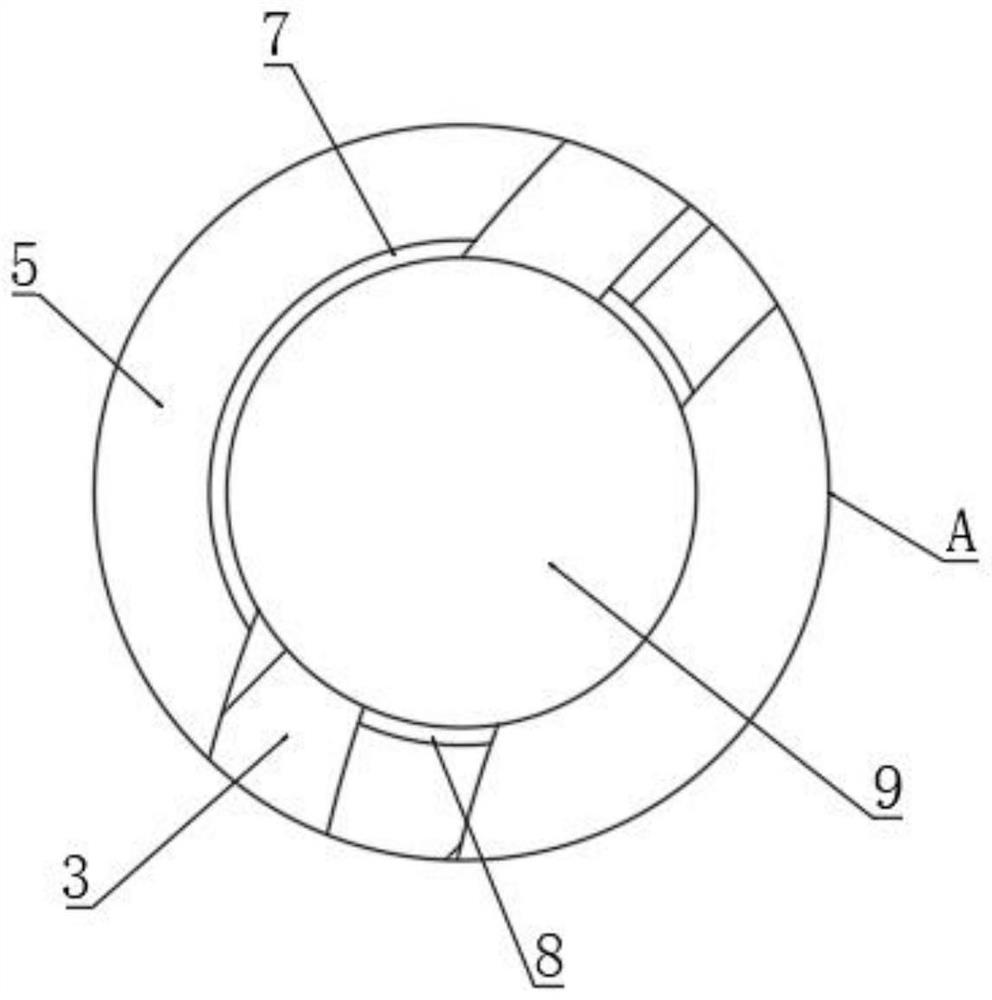

[0024]Such asfigure 1 ,figure 2 ,image 3 As shown, an electric vehicle damping mechanism includes a support rod 1, a telescopic rod 2 having a telescopic rod 2, a surface cover of the telescopic rod 2, and a sponge 5 in the surface of the labore 3, the inside of the lubricating sleeve 3. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com