Damping mounting base of electrical equipment for wind power generation

A technology for installing bases and electrical equipment, applied in mechanical equipment, springs/shock absorbers, non-rotational vibration suppression, etc., can solve problems such as large swings and vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

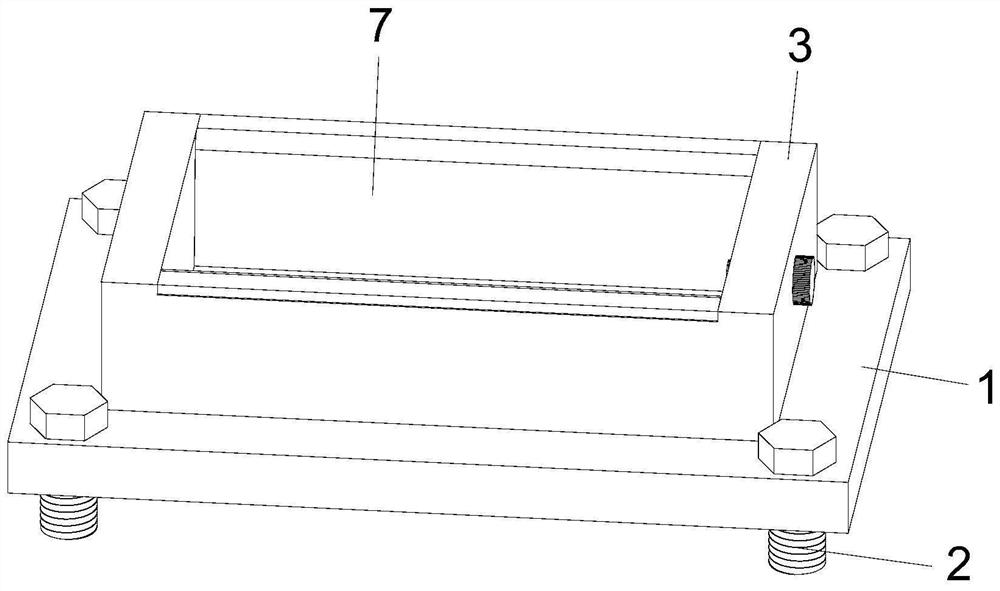

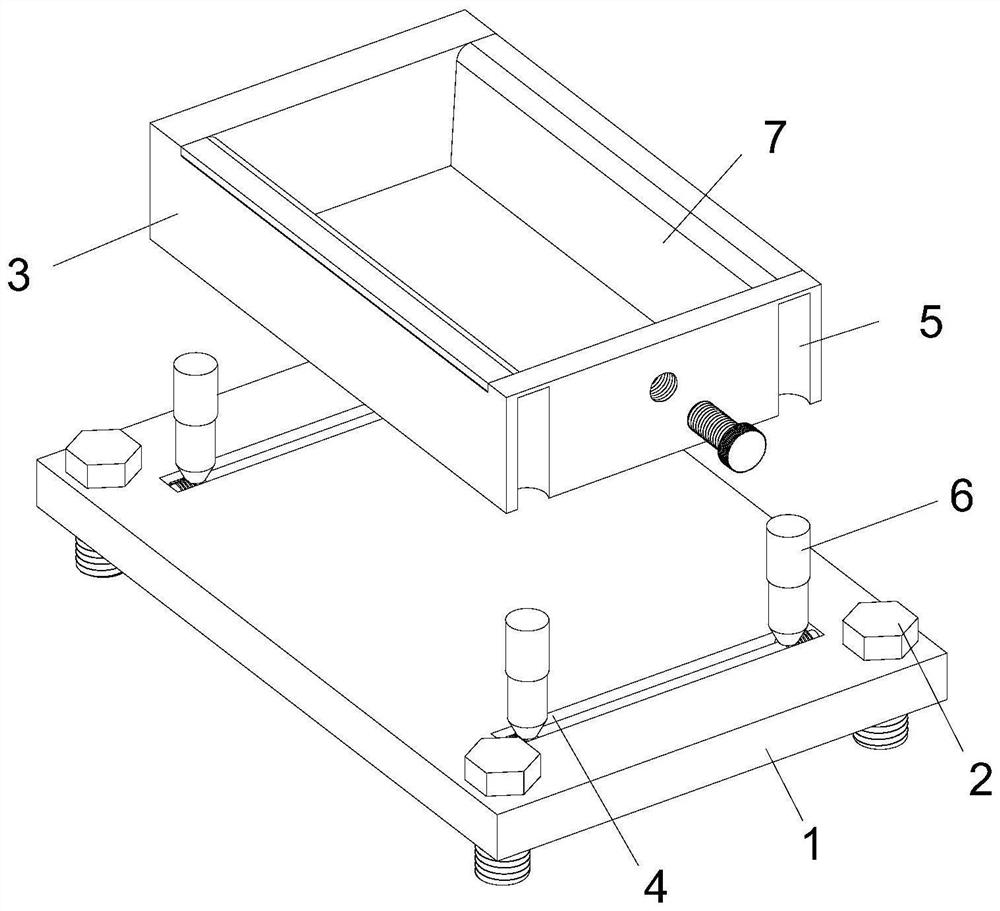

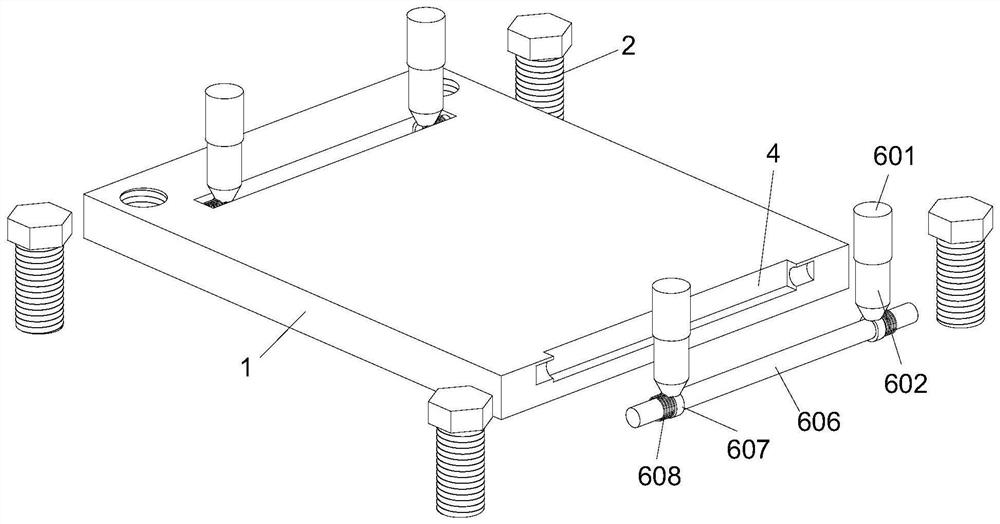

[0028] Please refer to Figures 1-4, a shock-absorbing mounting base for electrical equipment used in wind power generation, including a mounting base 1, with bolts 2 downwards at the four corners of the top surface of the mounting base 1, and a fixing frame 3 in the middle of the top surface of the mounting base 1 , the position of the top surface of the mounting seat 1 relative to the bottom surface of the fixed frame 3 is in a front-rear symmetrical structure, and a chute 4 is provided, and the four corners of the bottom surface of the fixed frame 3 are set up with a limit groove 5 relative to the position of the chute 4, and the inside of the limit groove 5 is provided. Vibration component 6, fixed frame 3 is provided with fixed component 7 inside.

[0029] The bottom surface of the fixing frame 3 is in clearance fit with the top surface of the mounting base 1 .

[0030] The shock absorbing assembly 6 includes a sleeve 601, which is slidably connected to a limit tube 602 in...

Embodiment 2

[0035] Please refer to Figure 5, the difference in the basis of Embodiment 1 is that the fixing assembly 7 includes two fixing plates 701, the fixing plates 701 are symmetrically arranged inside the fixing frame 3, and the fixing plates 701 are arranged in an L-shaped structure, The fixed plate 701 inwall is inclined result setting, and the fixed plate 701 rear end is evenly provided with and is fixed with a plurality of springs B702, and the spring B702 outer end is connected and fixed with the fixed frame 3 inwalls, and the fixed frame 3 right-hand middle part is provided with the fixed bolt 703.

[0036]In the present invention, by setting the inner wall of the fixing plate 701 as an inclined result, the upward opening area of the fixing frame 3 is increased, and it is convenient to place the electrical equipment inside the fixing bracket 3, and at the same time, when the electrical equipment is placed inside the fixing bracket 3, the front and rear end faces are extruded a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com