Device for regulating and controlling low-frequency sound insulation performance of sandwich plate structure and parameter determination method thereof

A technology for determining structural parameters and parameters, applied in chemical instruments and methods, sound-producing instruments, layered products, etc., can solve the problems of low calculation efficiency and large time complexity of the ergodic method, and achieve the effect of improving low-frequency sound insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

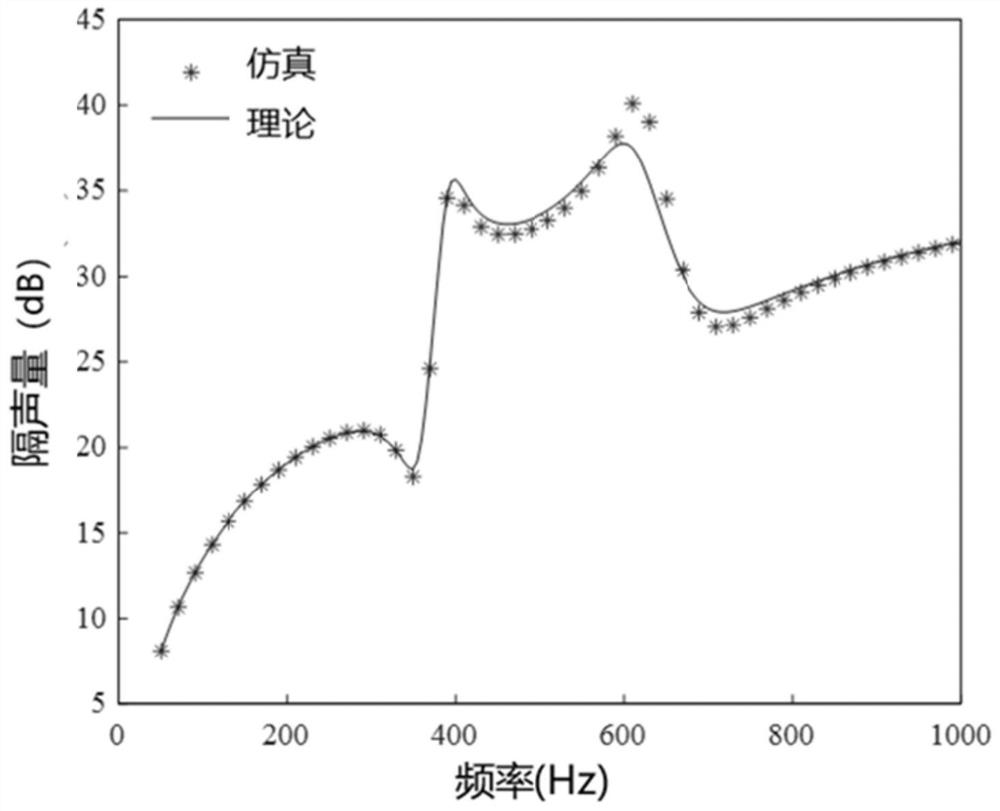

[0052] Taking the UHV converter transformer as an example, the low-frequency components of the noise generated by it are relatively significant and have obvious modulated noise at 100Hz and its high-order harmonics. Conventional sound insulation measures are difficult to achieve a good noise reduction effect. For this reason, for the low-frequency noise radiated by the UHV converter transformer, especially its 3rd harmonic (300Hz) and 4th harmonic (400Hz) noise, the device of this embodiment is designed outside the converter transformer shell, and the The structural parameters of the device are designed in a targeted manner to effectively reduce the 300Hz and 400Hz harmonic noise radiated by it.

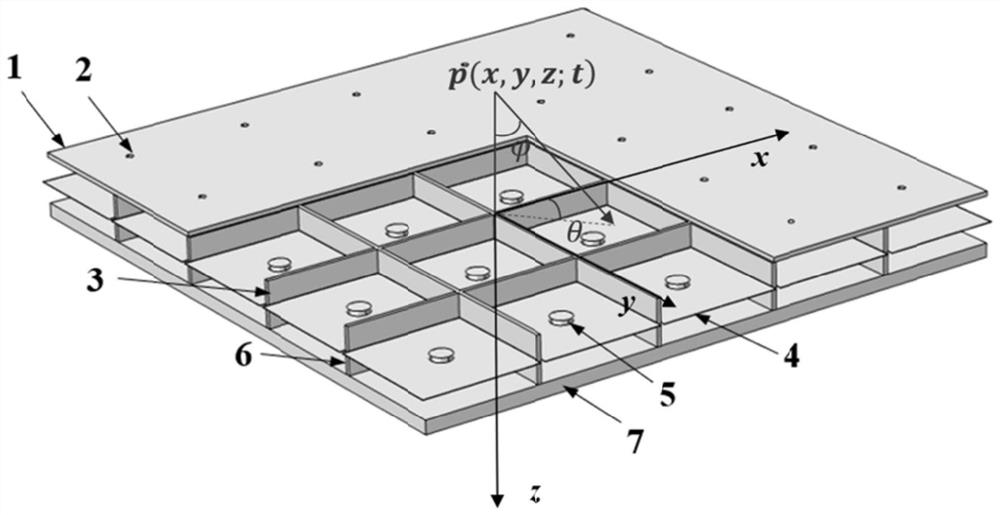

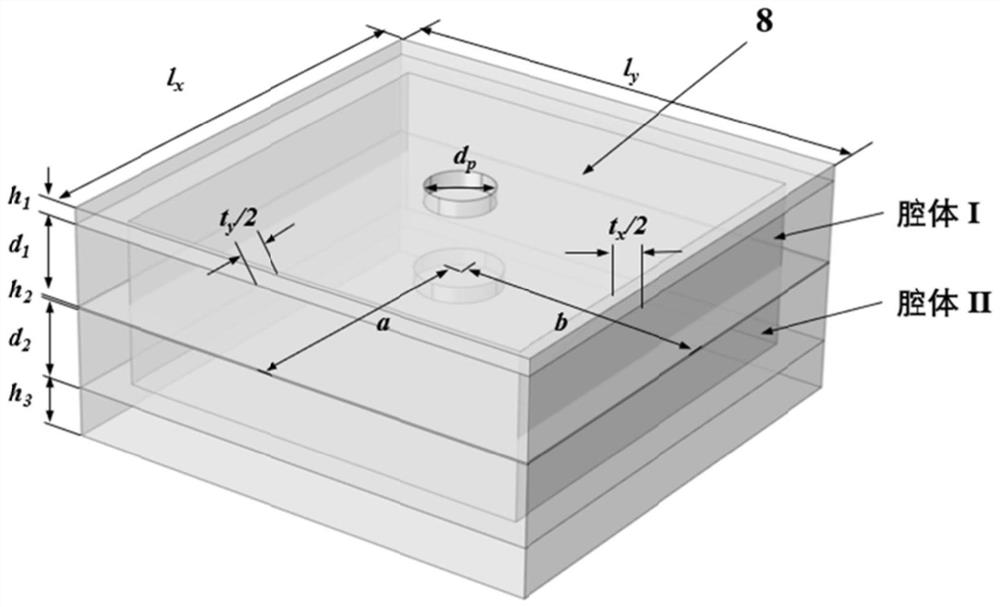

[0053] see figure 1 with figure 2 In this embodiment, the device for controlling the low-frequency sound insulation performance of the sandwich panel structure is a sandwich panel structure composed of periodic units 8, and each periodic unit 8 includes a perforated upper panel 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com