Cup material of passive noise reduction earmuffs

A technology of passive noise reduction earmuffs and cups, which is applied in earphones to reduce environmental noise, handset/earphone accessories, earphone manufacturing/assembly, etc. It can solve the problems of low sound insulation performance in the middle and low frequency bands, and achieve improved sound insulation performance, Simple, reliable, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A cup material for passive noise reduction earmuffs, based on the total mass of the cup material as 100%, the composition of the cup material and the mass percentage of each component are as follows: ABS 79%, SIR (damping coefficients greater than 0.2) 17% and PC 4%.

Embodiment 2

[0016] A cup material for passive noise reduction earmuffs, based on the total mass of the cup material as 100%, the composition of the cup material and the mass percentage of each component are as follows: ABS 75%, SIR (damping coefficients greater than 0.2) 18% and PC 7%.

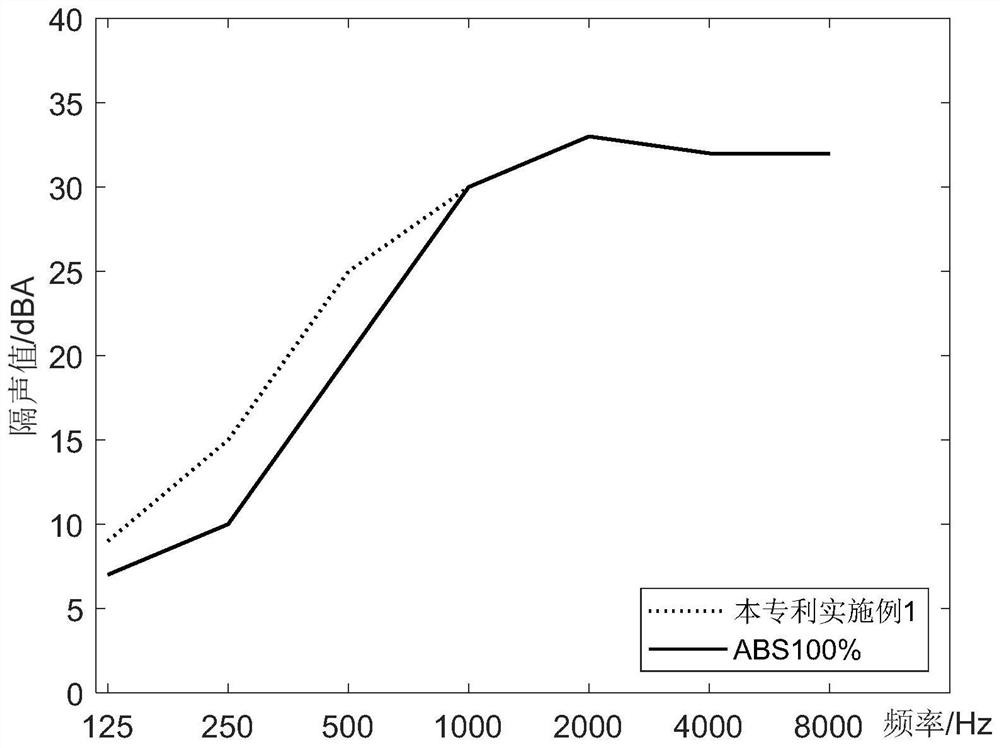

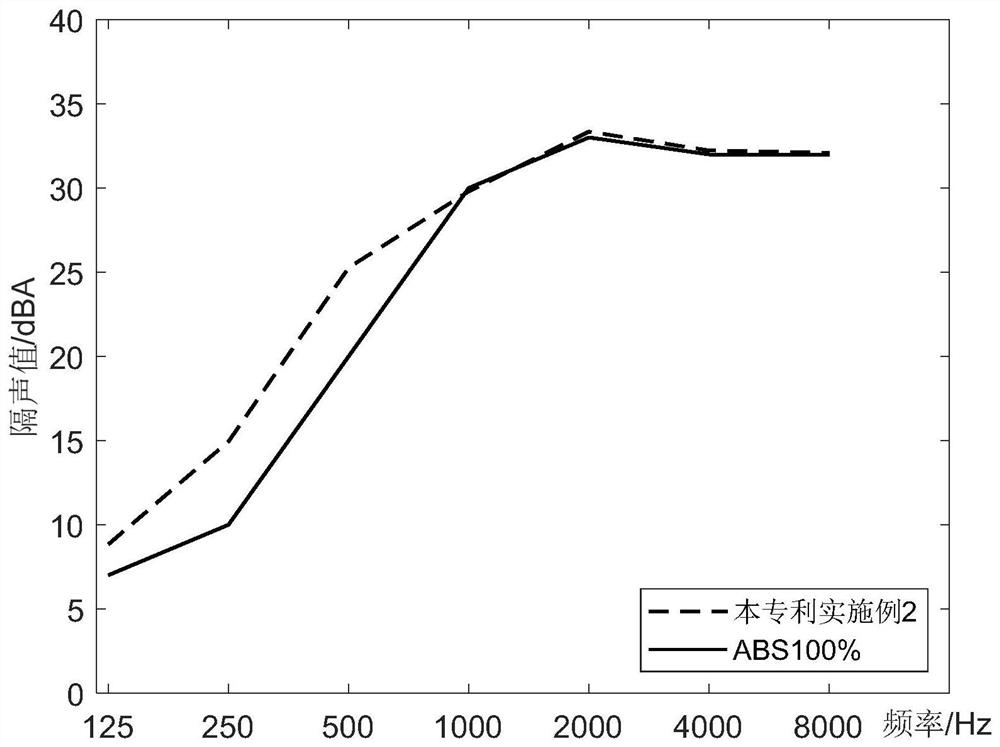

[0017] The cup materials and ABS materials in Examples 1 to 2 were used to prepare three cups with the same size and structure, and the three cups were assembled into three single-cup earmuffs with the same structure, that is, except for the different cup materials, other parameters All are the same, the size of the earmuffs conforms to the M type of the standard GB / T 2428 adult head and face size, and the clamping force of the earmuffs is 9.5N. Three earmuffs were tested for sound insulation frequency performance under the same conditions. For details, see the test results. figure 1 and figure 2 . Among them, the instruments involved in the test include: the sound level meter is Denmark BK22032, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com