A small hand-held laser head for laser cleaning

A laser cleaning and hand-held technology, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as damage, troublesome operation, and affecting equipment quality, so as to improve the cleaning effect and avoid secondary oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

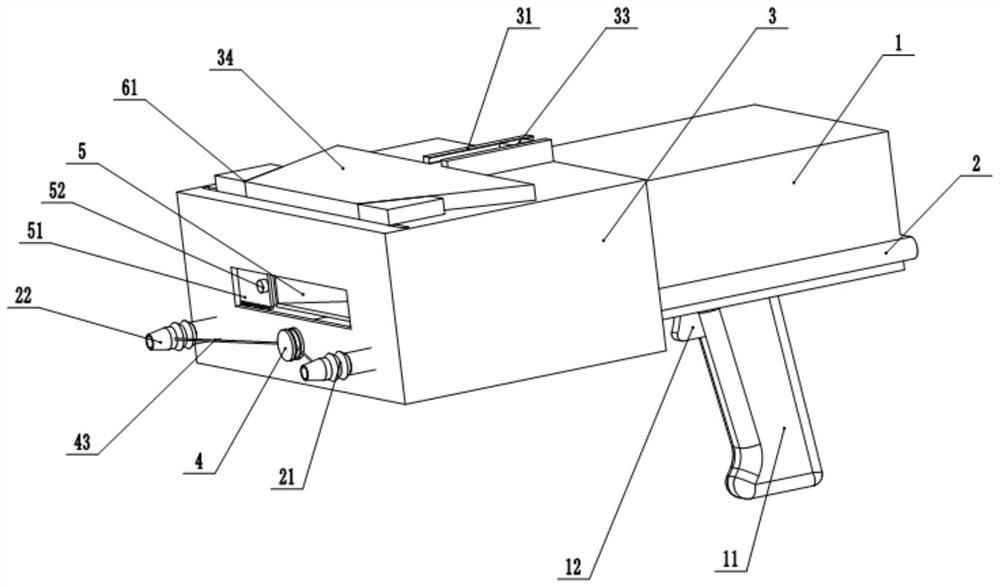

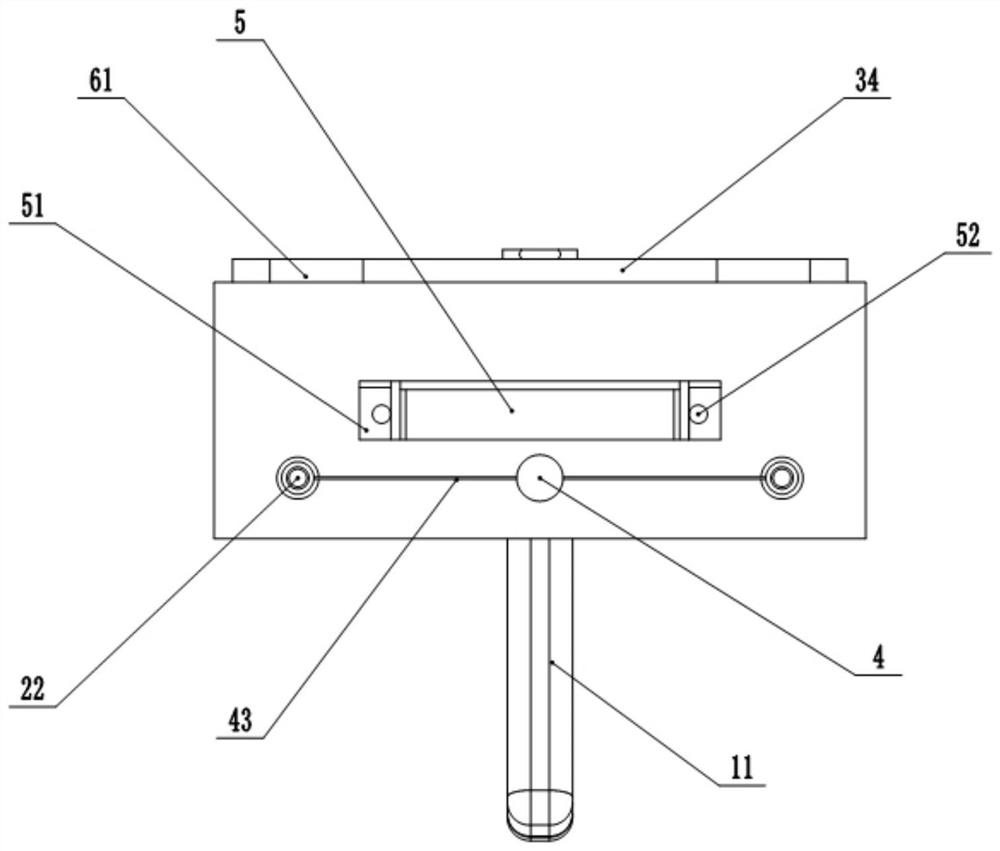

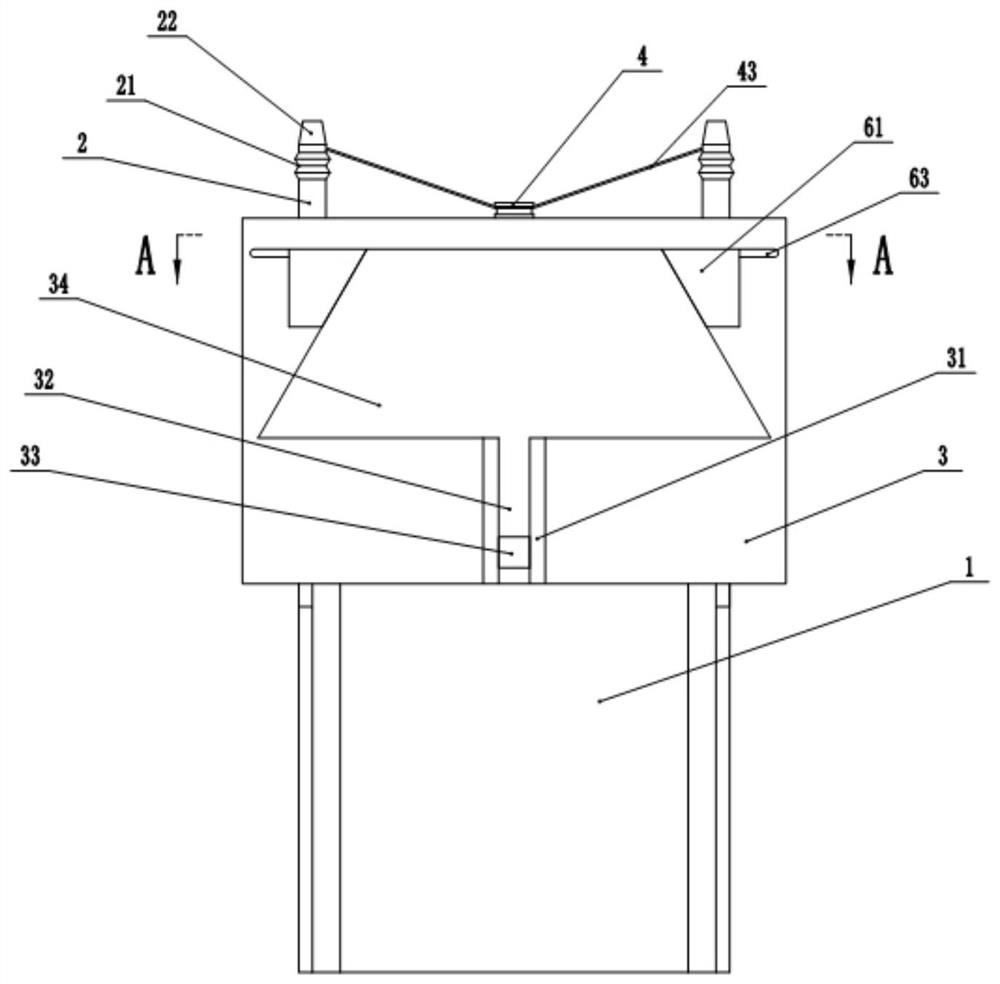

[0028] A small hand-held laser head for laser cleaning, such as Figures 1 to 6 As shown, it includes a housing 1, a control circuit and an optical element (not shown) are arranged in the housing 1, a grip handle 11 is installed at the bottom of the housing 1, and a grip handle 11 is installed on the grip handle 11 for controlling the output of the laser beam The control switch 12 is connected to the control circuit; the optical element is used for laser beam shaping and deflection, and the control circuit is used to control the beam deflection, and the laser beam is irradiated on the object to be cleaned to form a beam with a certain width, the beam Can be used to clean all kinds of stains on the surface of objects.

[0029] The optical elements include a collimating mirror, a focusing mirror, a reflecting mirror, a scanning mirror and a transparent lens. The above-mentioned collimating mirror, focusing mirror, reflecting mirror, scanning mirror and transparent lens are all a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com