A fire-proof and explosion-proof floating plate and fire-proof method

A technology of floating discs and sealing discs, which is applied in the field of fire-proof and explosion-proof floating discs and fire protection, and can solve problems such as increased costs, inability to detect oil storage tanks, and large probe limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

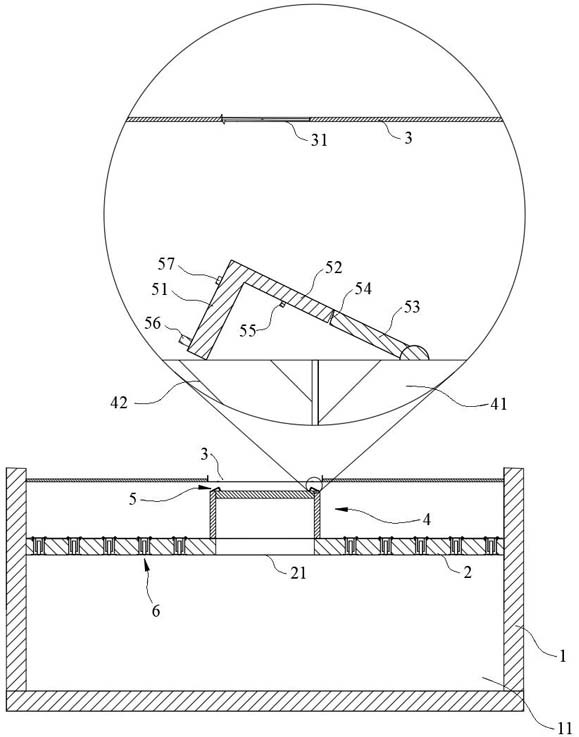

[0029] The traditional storage tank includes a storage tank body 1 and a floating plate body 2 slidingly connected in the storage tank body 1, and a storage tank suitable for filling oil is formed between the storage tank body 1 and the floating plate body 2. The oil cavity 11, through the discharge of the oil in the oil storage cavity 11, makes the floating plate body 2 go up and down, and the floating plate body 2 plays a role in reducing the volatilization loss of the oil in the oil storage cavity 11 As a result, it is usually required that the floating disc body 2 and the inner side wall of the storage tank body 1 be in close contact, so as to realize the sealing between the floating disc body 2 and the inner side wall of the storage tank body 1, and such a design is when the oil storage cavity 11 When an explosion occurs, the entire floating plate body 2 will be damaged due to the seal between the floating plate body 2 and the inner wall of the storage tank body 1. At the ...

Embodiment 2

[0046] On the basis of the first embodiment, the second embodiment also provides a fire prevention method for the fireproof and explosion-proof floating tray, wherein the structure of the fireproof and explosion-proof floating tray is the same as that of the first embodiment, and will not be repeated here.

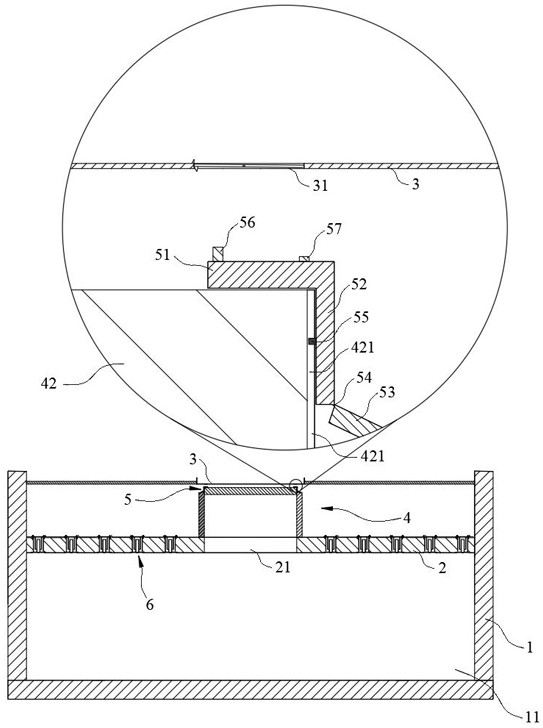

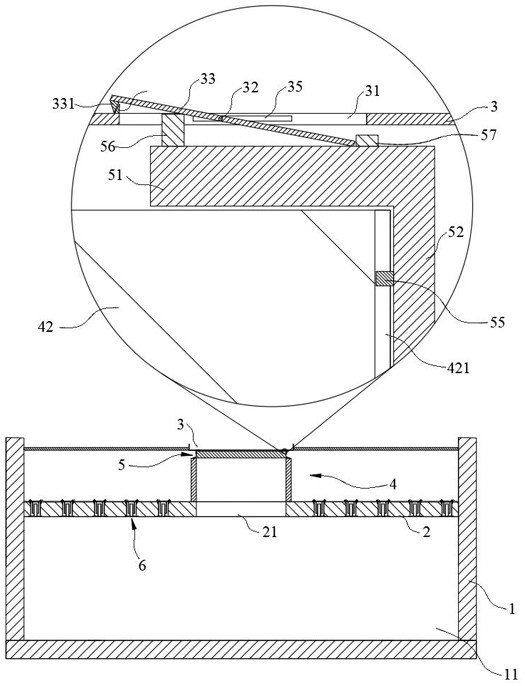

[0047]Specifically, when the pressure in the oil storage cavity 11 increases, the sealing disc 42 is pushed up; the upper blocking piece 51 is pushed up by the sealing disc 42 until the upper blocking piece 51 is attached to the upper end surface of the sealing disc 42 and the middle blocking piece 52 Fit the outer wall of the sealing disc 42 so that the upper stopper 51 blocks the sealing disc 42 from coming out of the sealing sleeve 41; when the pressure in the oil storage cavity 11 continues to increase to exceed the maximum stress of the crease 54, the crease 54 breaks off, and the upper blocking piece 51 continues to be pushed by the sealing disc 42; when the upper blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com