Light workpiece grabbing device for machining

A grasping device and machining technology, applied in the field of machining, can solve the problems of many linkage mechanisms of the grasping device and complicated grasping devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

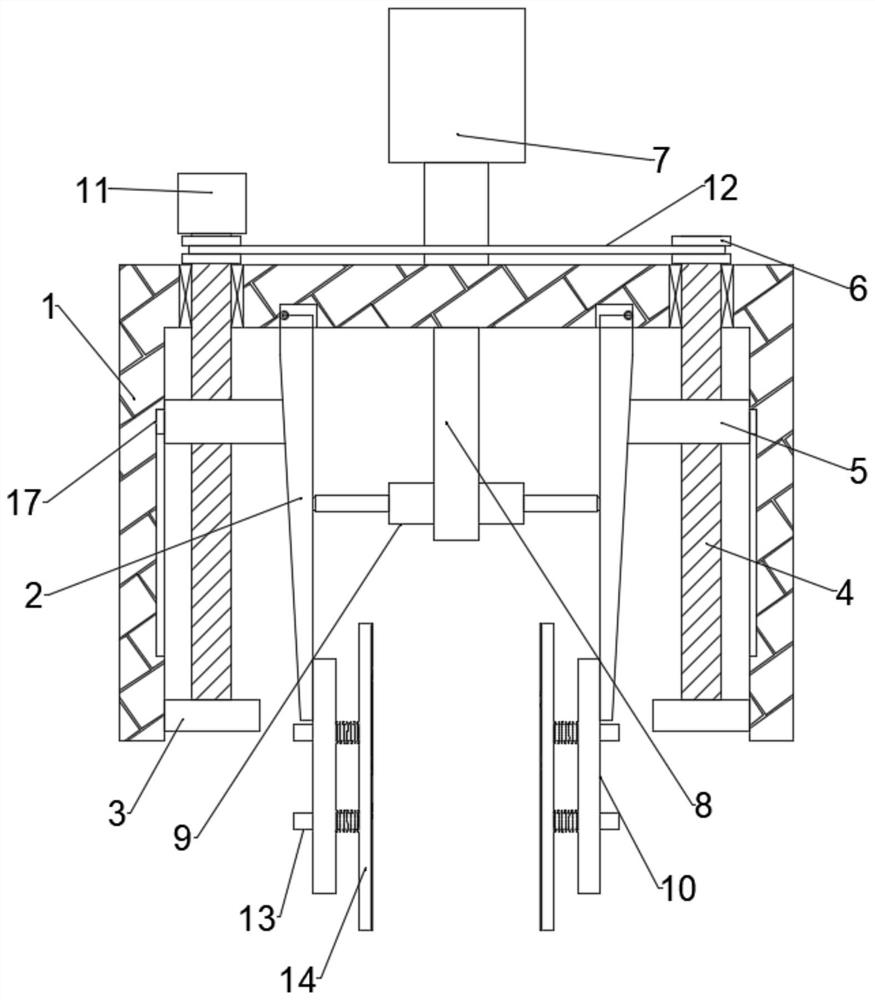

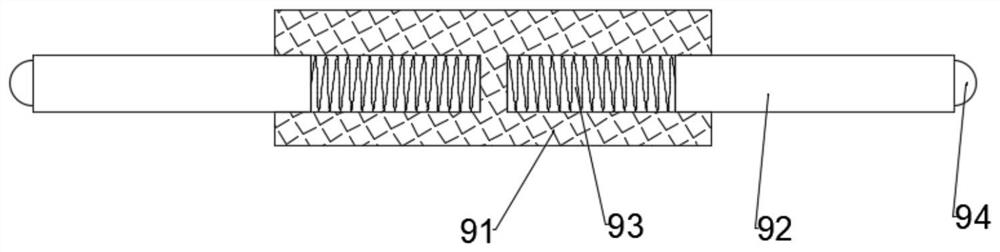

[0022] combine Figure 1-4 , a light-duty workpiece grabbing device for mechanical processing, comprising an electric push rod 7, a mounting frame 1 is installed on the movable end of the electric push rod 7, and two wedge-shaped plates 2 are connected to the inside of the mounting frame 1 for rotation, and The two wedge-shaped plates 2 are arranged symmetrically about the center of the mounting frame 1, and a threaded rod 4 is arranged between the two wedge-shaped plates 2 and the inner wall of the mounting frame 1, and one end of the threaded rod 4 is fixed to the mounting frame. The fixed plate 3 on 1 is connected by rotation, and the other end is connected with the driving mechanism through the upper end of the installation frame 1. The threaded rod 4 is threaded with a threaded block 5, and one end of the threaded block 5 slides with the inner wall of the installation frame 1. connection, the other end is in contact with the slope of the wedge-shaped plate 2, and the midd...

Embodiment 2

[0031] combine Figure 1-2 , a light-duty workpiece grabbing device for mechanical processing. This embodiment further limits the invention on the basis of Embodiment 1.

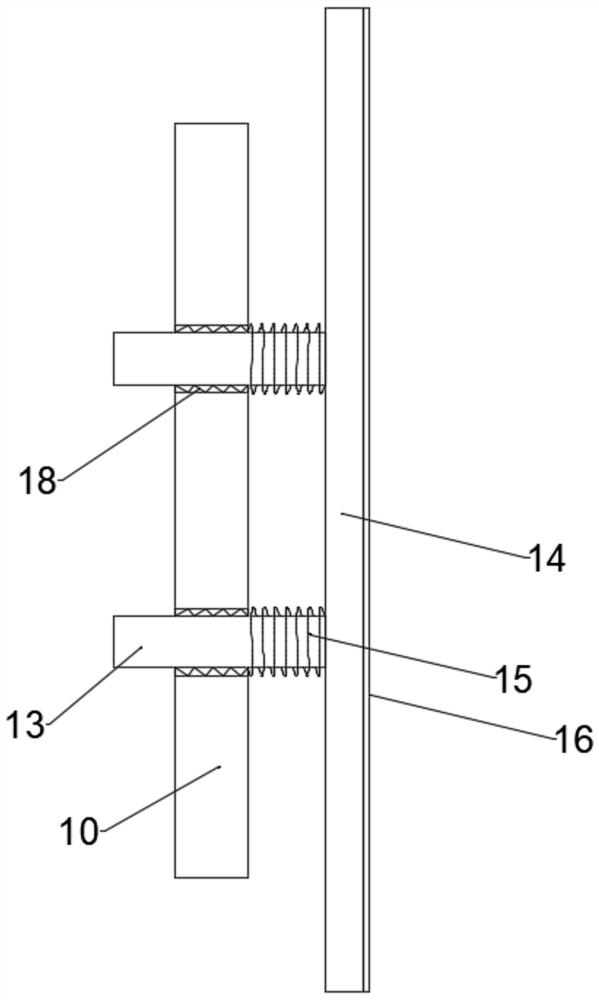

[0032] A plurality of connecting rods 13 all pass through the mounting plate 10 and are slidably connected with the mounting plate 10. A second spring 15 sleeved on the outside of the connecting rod 13 is connected between the mounting plate 10 and the splint 14. 13 all run through the mounting plate 10 and are slidably connected with the mounting plate 10, so that the second spring 15 can be used to achieve buffering when grabbing, and avoid damage to light workpieces caused by large clamping forces.

[0033] The mounting plate 10 and the outer side of the connecting rod 13 are all embedded with a sliding sleeve 18, and the connecting rod 13 is slidably connected with the sliding sleeve 18. The sliding connection between the connecting rod 13 and the sliding sleeve 18 facilitates the smooth and stable opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com