Manufacturing process of foaming earmuff of integrated seamless structure

A technology of seamless structure and production process, applied in the field of earmuff design, can solve problems such as seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

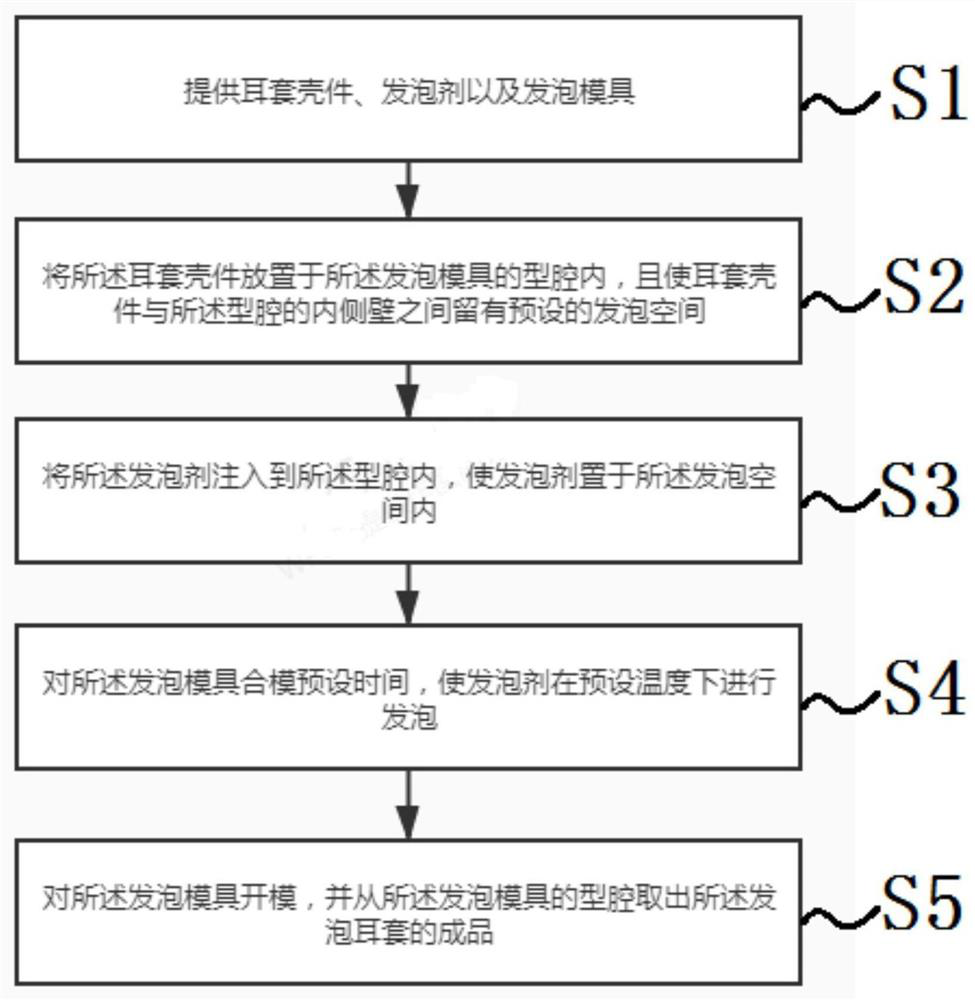

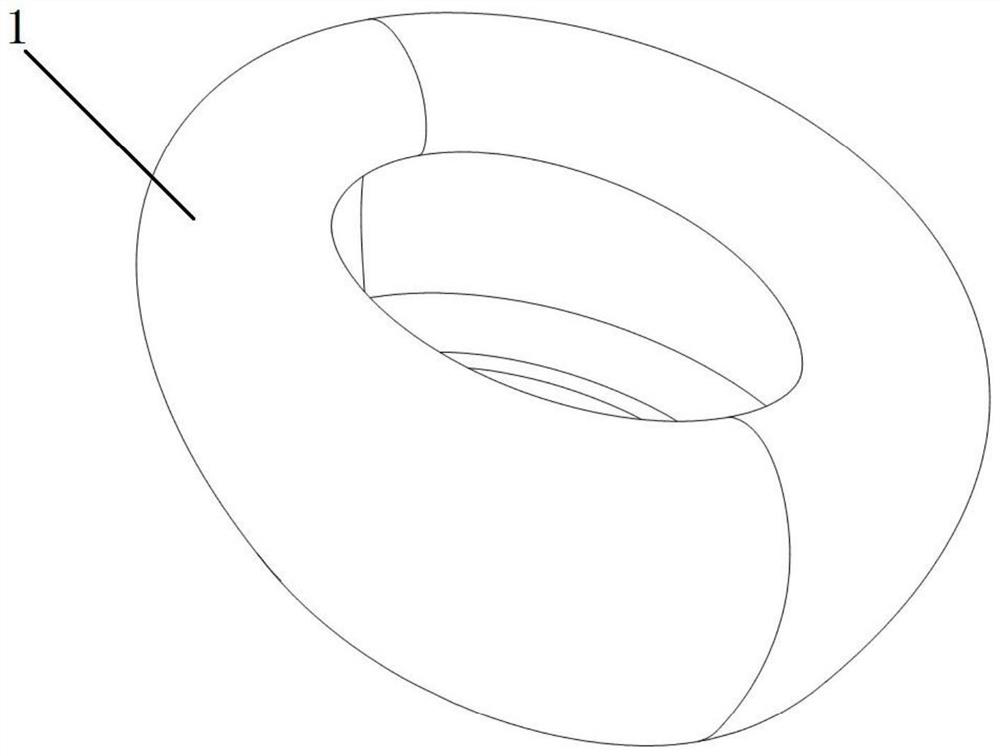

[0047] see Figure 1 to Figure 10 , an integrated seamless structure foam earmuff manufacturing process in the embodiment of the present invention, comprising:

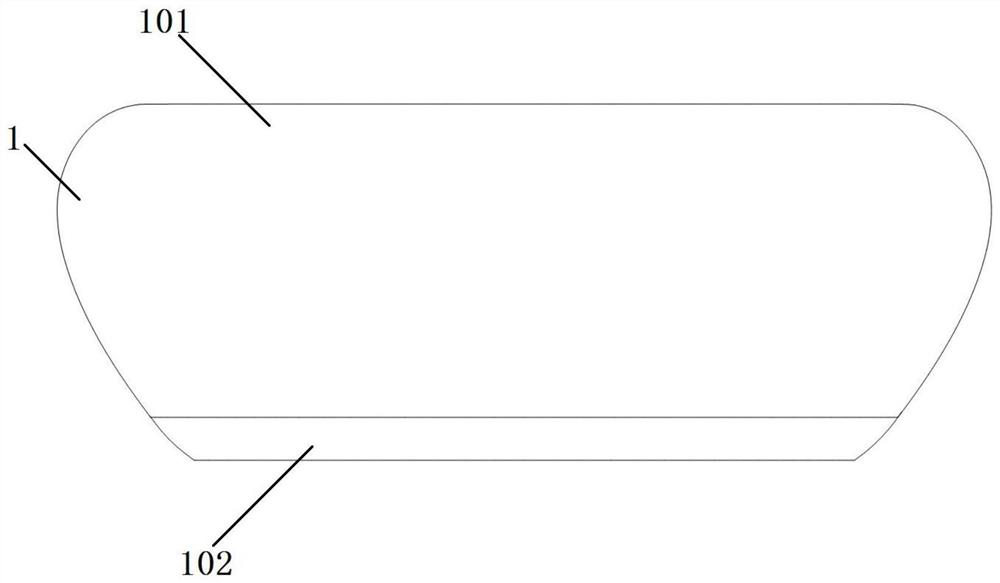

[0048] S1, providing the earmuff shell 102, foaming agent and foaming mold;

[0049] Specifically, the earmuff shell 102 may be in the form of a ring structure, which varies according to different types of earphones, and this embodiment does not limit the shape of the earmuff shell 102;

[0050] S2. Place the earmuff shell 102 in the cavity of the foaming mold, and leave a preset foaming space between the earmuff shell 102 and the inner side wall of the cavity;

[0051] S3, injecting the foaming agent into the mold cavity, placing the foaming agent in the foaming space;

[0052] S4. Clamping the foaming mold for a preset time, so that the foaming agent foams at a preset temperature;

[0053] S5. Open the foaming mold, and take out the finished product 1 of foaming earmuffs from the cavity of the foaming mold.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com