Parallel-flow water circulation condenser

A water circulation and downstream technology, applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problem of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

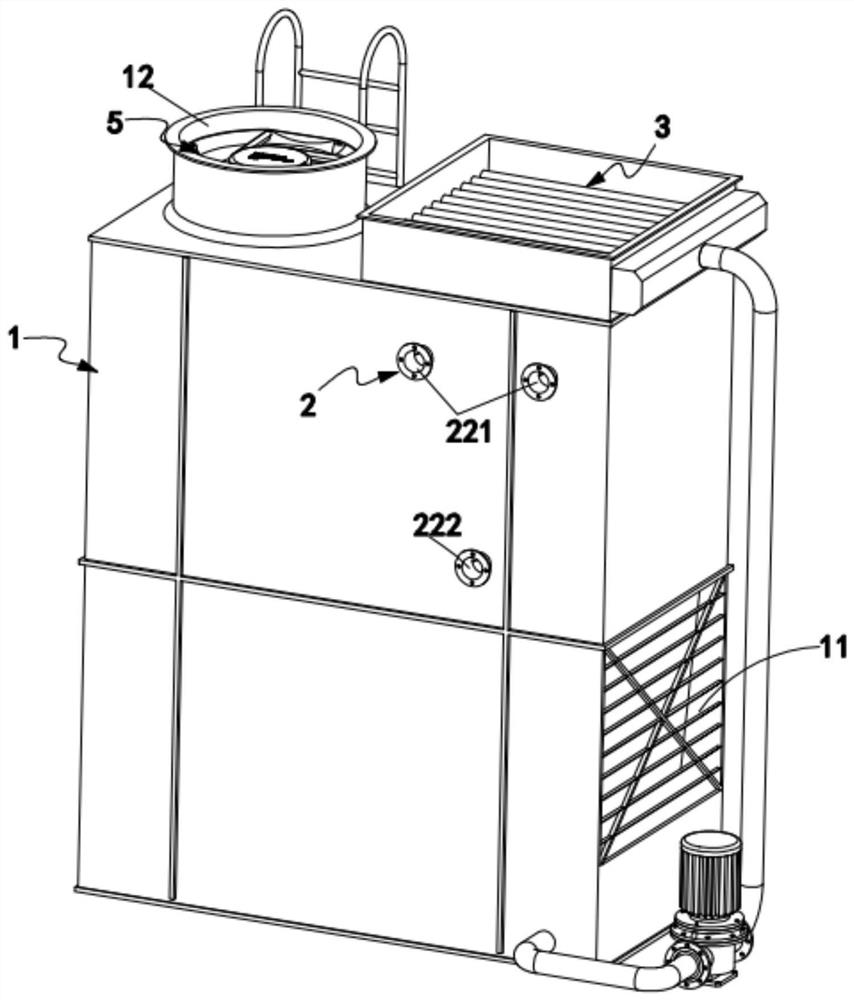

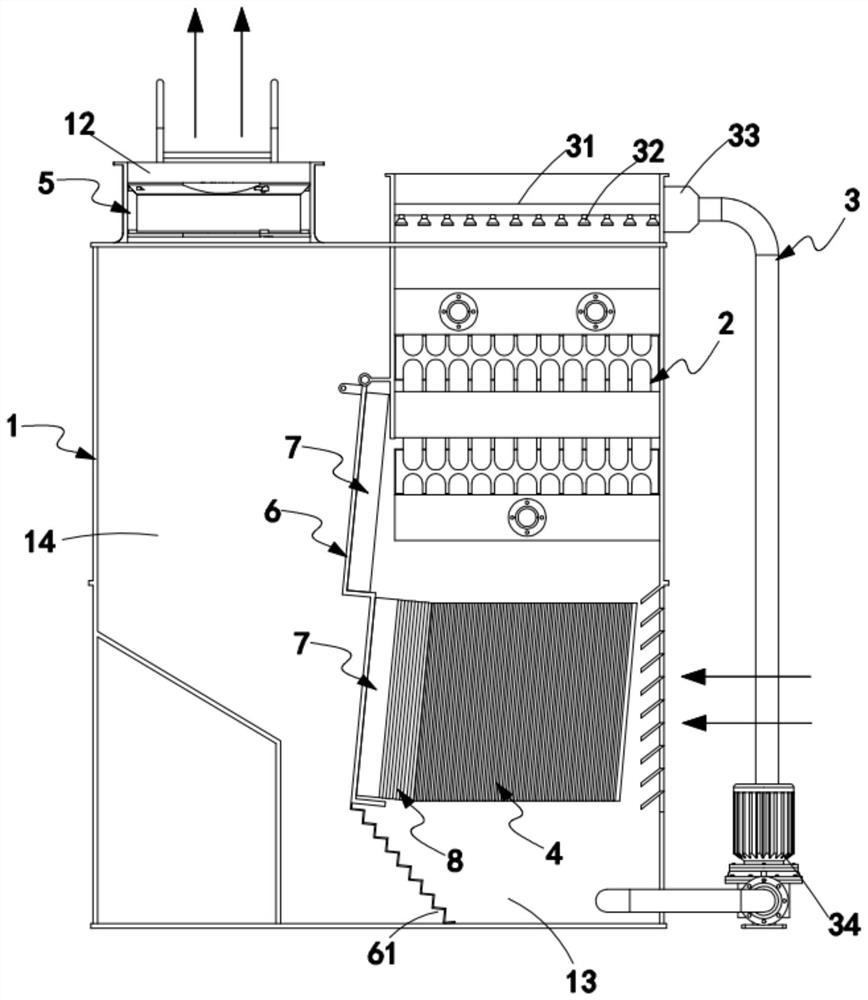

[0059] Such as Figure 1 to Figure 8 As shown, a downstream water circulation condenser includes a housing 1, a cooler 2, a spray mechanism 3, an auxiliary cooler 4 and a fan 5, and the housing 1 is provided with an air inlet 11 and an air outlet 12 respectively. , the cooler 2 is arranged in the housing 1 and the spray mechanism 3 is arranged above, the auxiliary cooler 4 is arranged under the cooler 2, and the fan 5 is arranged at the air outlet 12 :

[0060] A swinging partition 6 is arranged inside the housing 1, and through holes 61 are evenly distributed on the partition 6, and the partition 6 divides the housing 1 into a heat exchange area 13 and an exhaust area 14, so The air inlet 11 is arranged on the heat exchange area 13, the air inlet 11 is arranged facing the auxiliary cooler 4, and the air outlet 12 is arranged on the top of the exhaust area 14;

[0061] A liquid stagnation device 7 is installed on the part of the partition plate 6 facing the cooler 2 and the ...

Embodiment approach

[0070] Such as figure 2 As shown, as a preferred embodiment, the spray mechanism 3 includes:

[0071] Spray pipe 31, a number of said spray pipes 31 are horizontally installed directly above said cooler 2, and said spray pipe 31 is provided with a spray head 32 towards said cooler 2;

[0072] Connecting head 33, described connecting head 33 is positioned at one end of the length direction of described shower pipe 31, and this connecting head 33 communicates with all described shower pipes 31; And

[0073] Circulation pump 34, the circulation pump 34 is installed outside the housing 1, and the circulation pump 34 pumps the spray liquid in the housing 1 cooled by the auxiliary cooler 4 to the connector 33 recycle.

[0074] It should be noted that the circulating pump 34 reintroduces the liquid cooled by the auxiliary refrigerator 4 at the bottom of the housing 1 into the matching spray pipe 31 to achieve the purpose of circulating cooling.

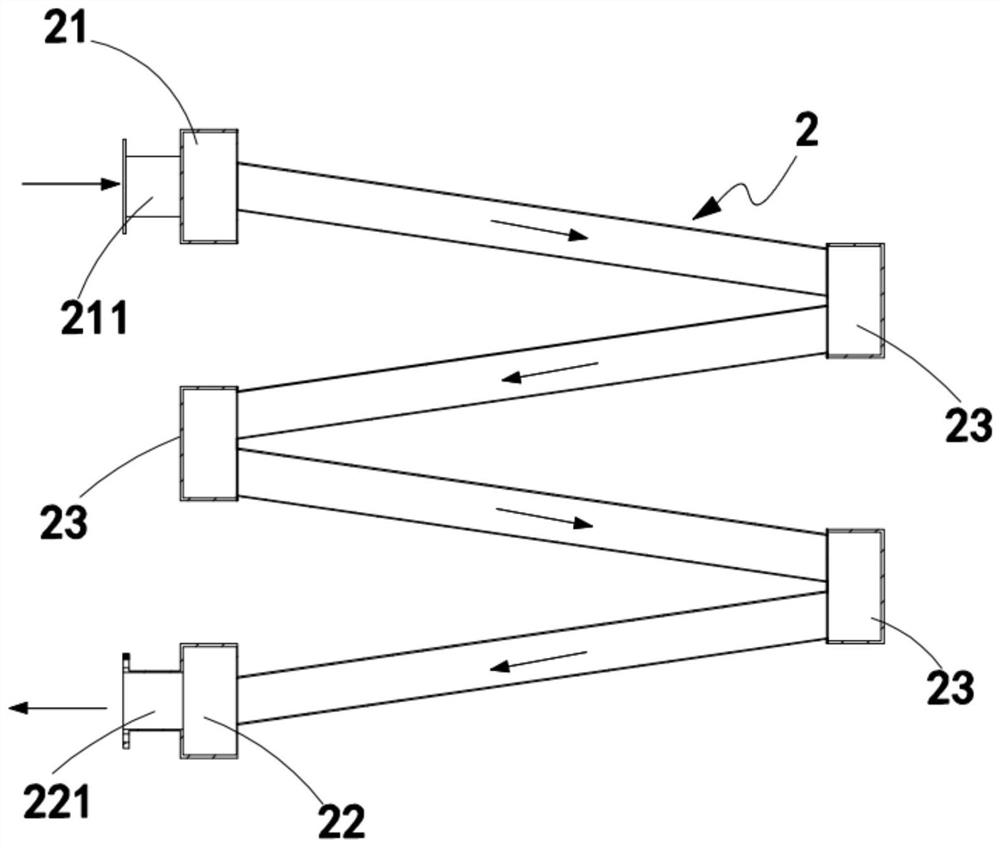

[0075] Such as figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com