Circulating quick-cooling efficient condenser

A condenser, high-efficiency technology, used in evaporators/condensers, refrigerators, refrigeration components, etc., can solve problems such as reduction, and achieve the effect of good heat exchange effect, ingenious structure, and good liquid retention effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

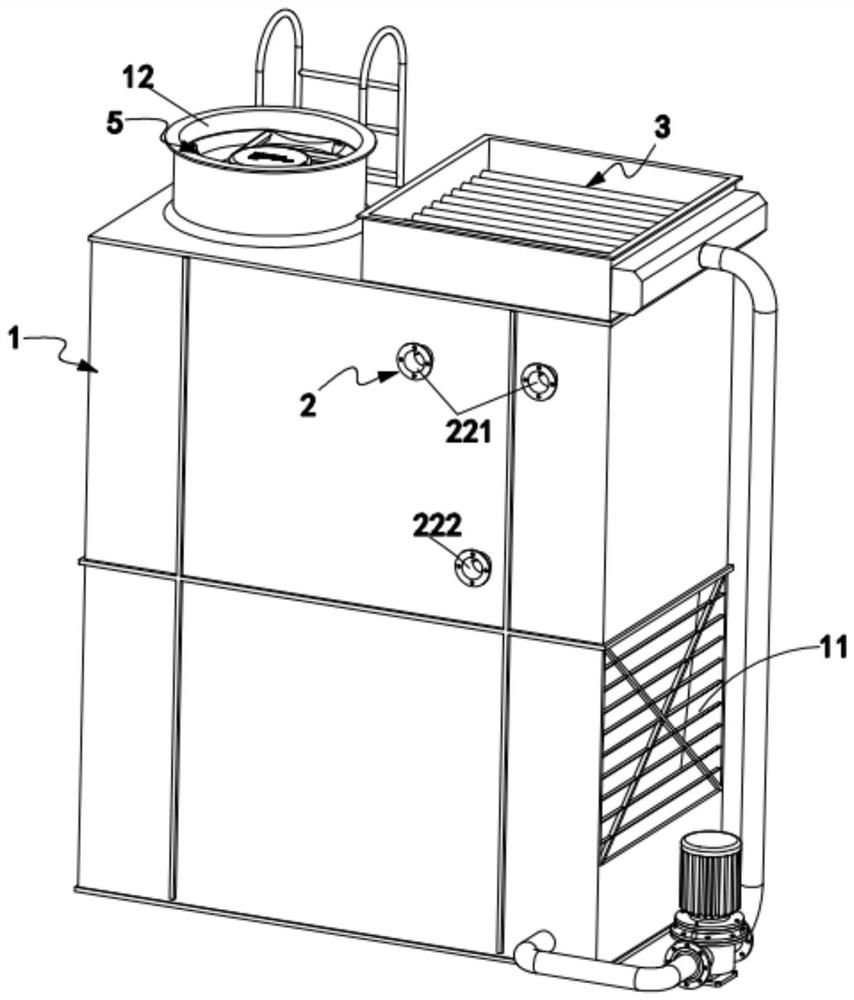

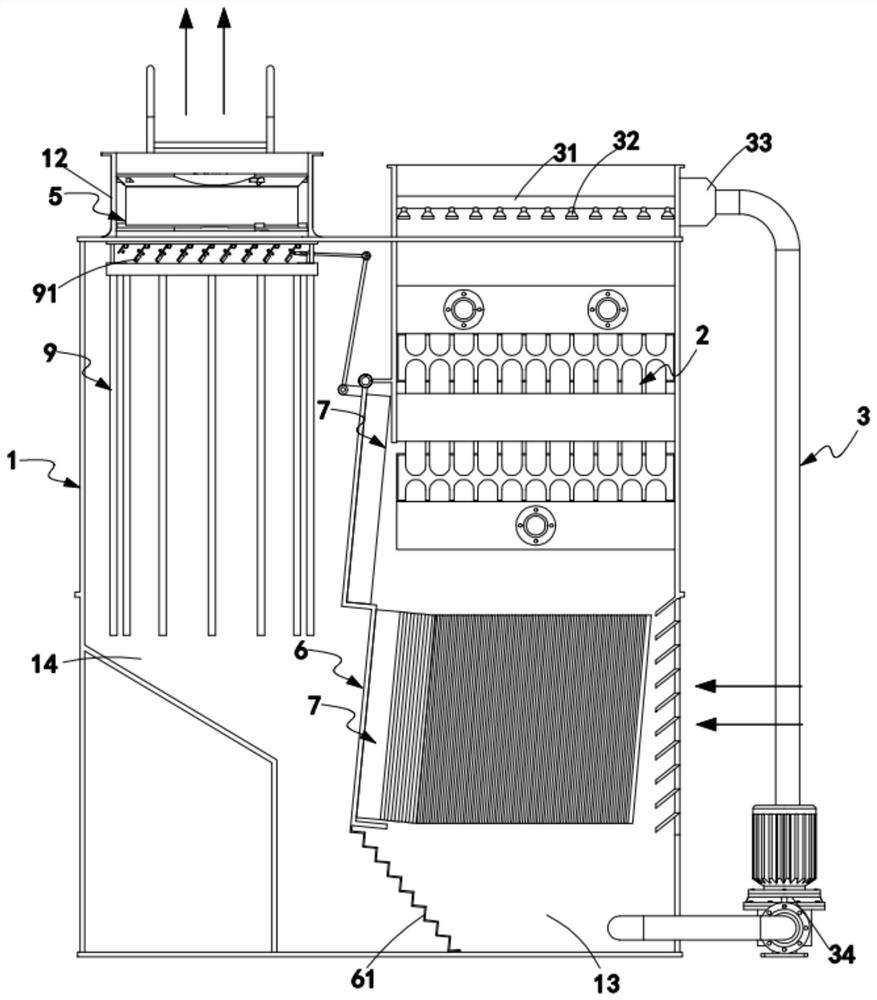

[0065] Such as Figure 1 to 5 As shown, a circulating quick-cooling high-efficiency condenser comprising housings 1, a cooler 2, a sprinkler 5, auxiliary cooler 4, and a fan 5, and the housing 1 is opened, respectively, and the air outlet 11 and the air opening 12, respectively. The cooler 2 is disposed in the housing 1 and the spray mechanism 3 is disposed above, and the cooler 2 is provided with an auxiliary cooler 4, and the fan 5 is disposed at 12 air outlets. It is characterized by:

[0066] The housing 1 is provided with a swing hole 61, and the separator 6 is spaced apart by separating the housing into a heat exchange zone 13 and a drain region 14. The vent 11 is disposed on the heat transfer region 13, which is disposed on the auxiliary cooler 4, and the air outlet 12 is disposed at the top of the exhaust region 14;

[0067] An end lag 9 is provided at the air outlet 12, which includes a plurality of blade 91 rotatably mounted at the air outlet 12, which is swayed by the s...

Embodiment approach

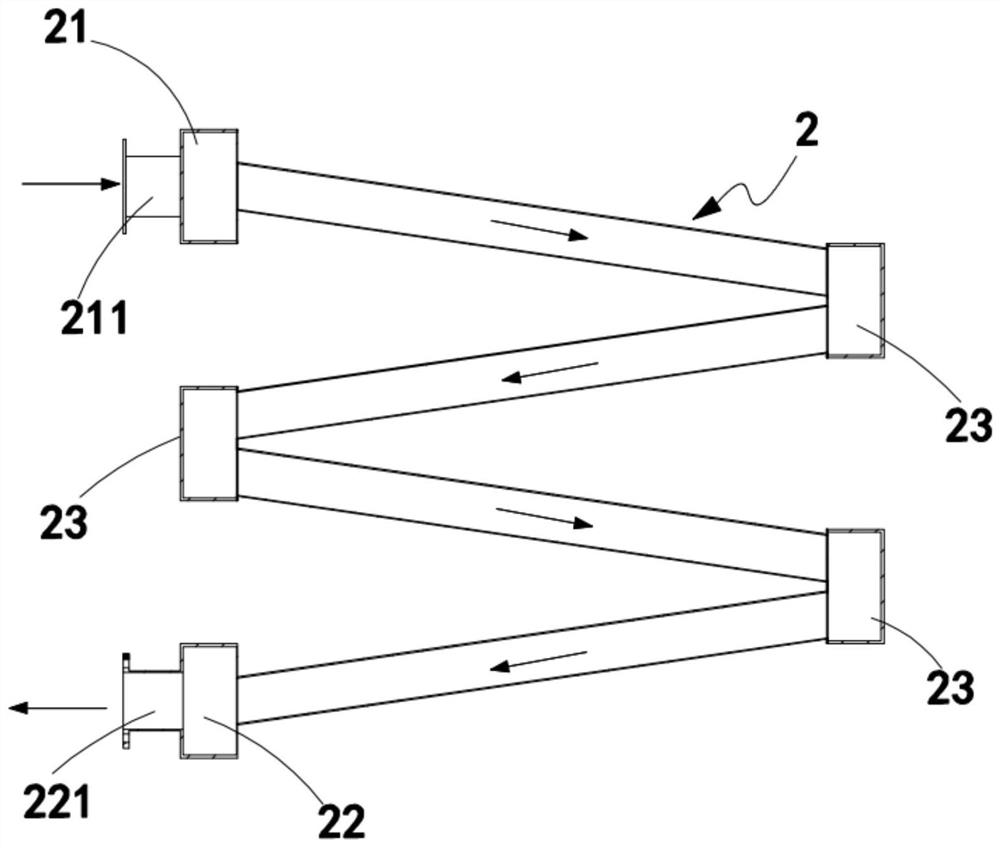

[0078] Such as figure 2 As shown, as a preferred embodiment, the spray mechanism 3 includes:

[0079] The spray tube 31, and several of the spray tubes 31 are mounted to the cooler 2, and the spray tube 31 is provided with nozzle 32 toward the portion of the cooler 2;

[0080] The connecting head 33 is located at one end of the spray tube 31, and the connecting head 33 communicates all of the spray tubes 31; and

[0081] The circulation pump 34 is mounted to the housing 1, and the circulating pump 34 is pumped to the housing 1, and the cooler 4 is switched to the jet liquid after cooling to the connecting head 33. recycle.

[0082] It should be noted that the circulating pump 34 re-inputs the liquid after cooling of the housing 1 through the auxiliary chiller 4, and reaches the purpose of circulating cooling.

[0083] Such as figure 2 As shown, as a preferred embodiment, the top portion of the separator 6 is hinged from the inner wall of the housing 1, and a spring plate 61 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com