Constant temperature and constant-humidity test box

A constant temperature and humidity test and test cabin technology, applied in the field of constant temperature and humidity test chambers, can solve the problems of inability to stabilize air pressure, high dependence on air pressure sensors, and inability to test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

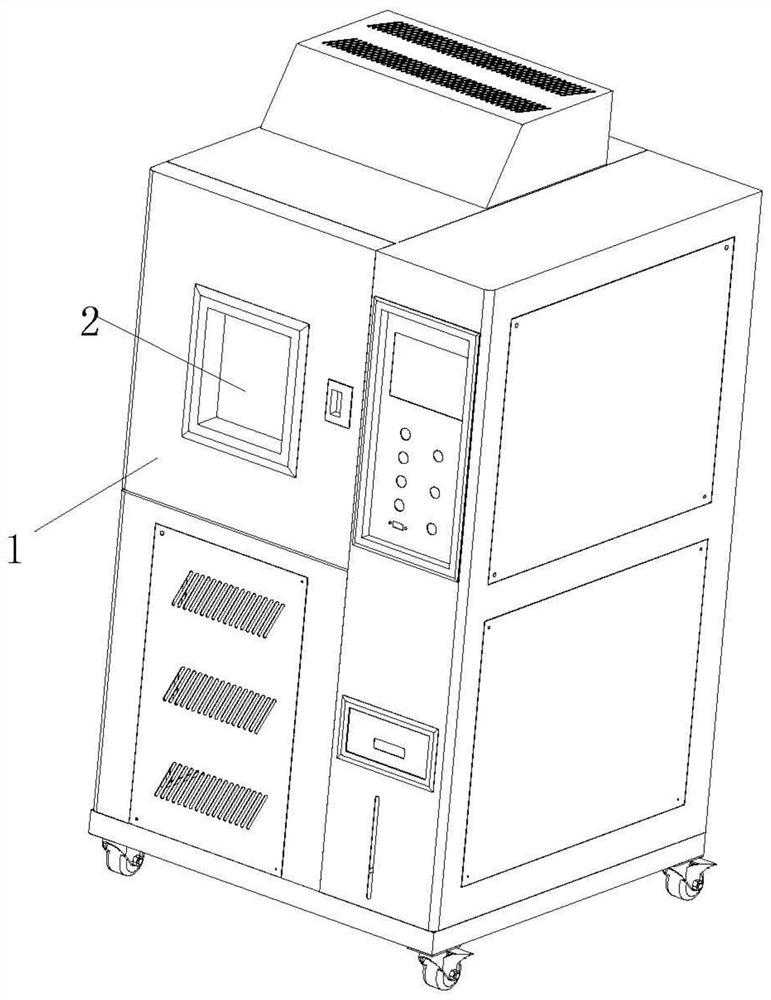

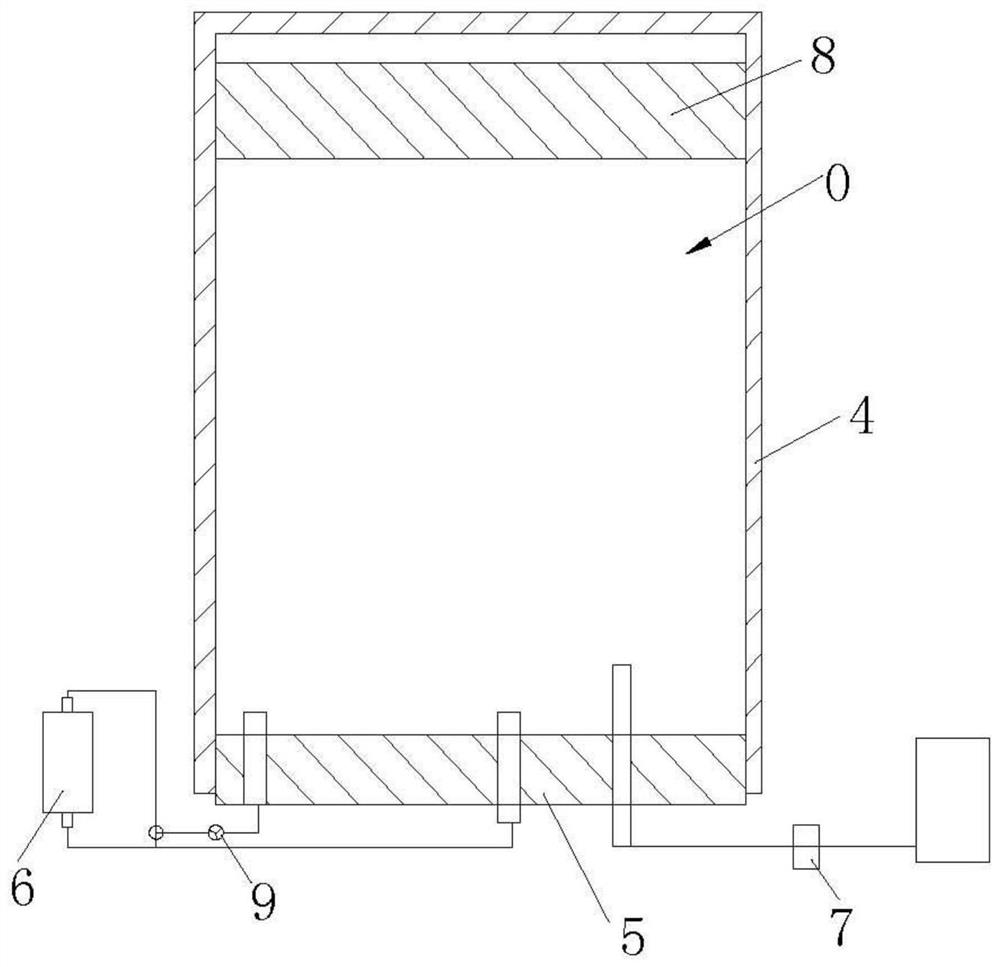

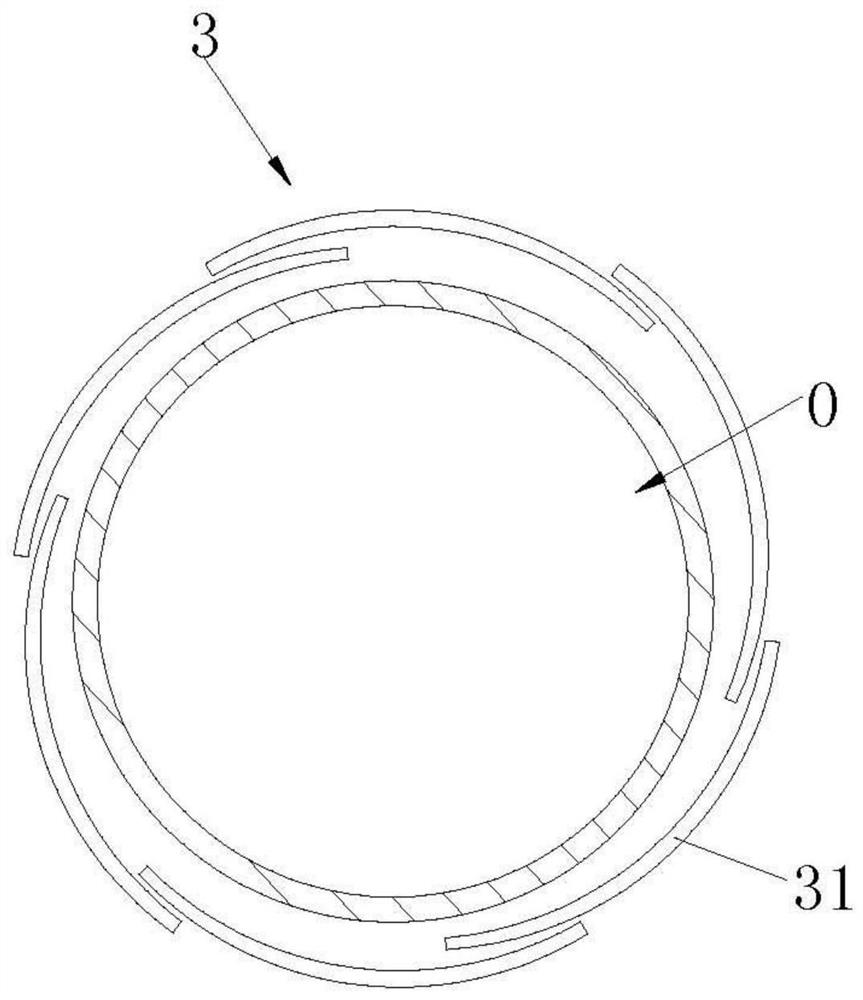

[0022] Such as Figure 1-3 As shown, the constant temperature and humidity test box of the present invention includes a heat insulation box 1 and a water tank, and the heat insulation box 1 is provided with a transparent observation window 2, and also includes a barrel-shaped test chamber 4 and a base 5 placed in a vertical direction. , a heating device, a refrigeration device, a humidifying device 7 and a counterweight piston 8, the base 5 is provided with a bracket for installing the sample; the counterweight piston 8 is freely slidable under the action of gravity and is arranged on the upper end of the barrel-shaped test chamber 4, The air pressure in the test chamber 4 is kept constant; the test chamber 4 is provided with a test space 0, and the test space 0 is located between the counterweight piston 8 and the base 5; the humidifying device 7 is used to add humi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com