Workpiece grabbing device with three-axis compensation mechanism

A compensation mechanism and grasping device technology, applied in the directions of manipulators, manufacturing tools, chucks, etc., can solve the problems that the mechanical gripper cannot successfully complete the work of grasping the workpiece on the chassis, the unevenness of the platform on which the chassis is placed, and the operating frequency and quantity are large. Achieve the effect of improving grabbing efficiency, saving beats and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

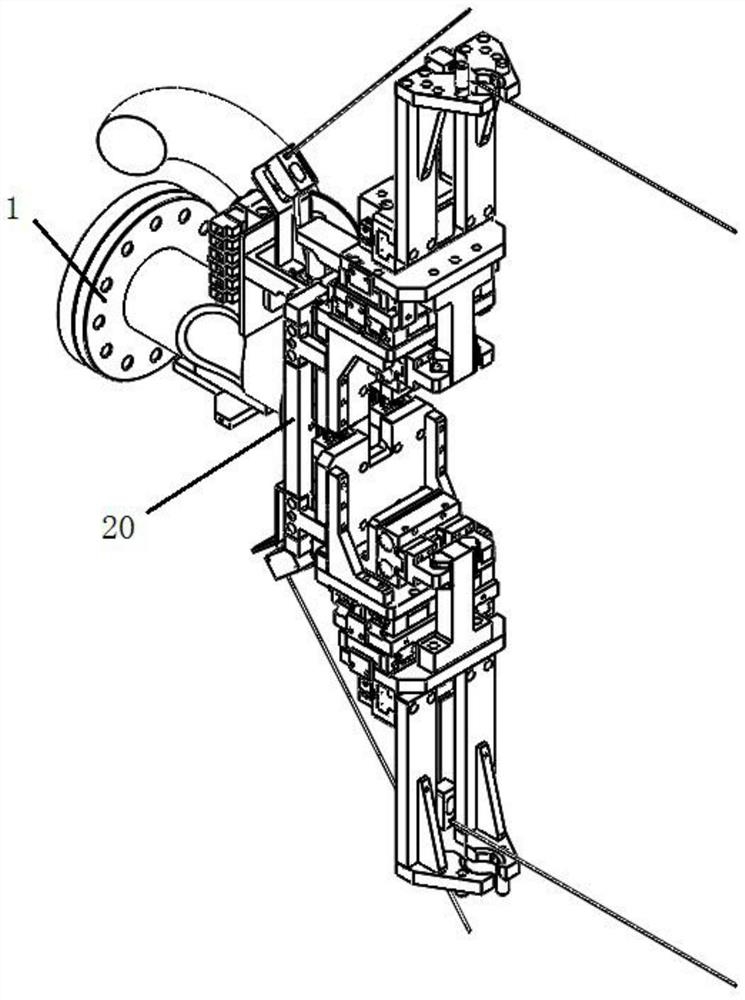

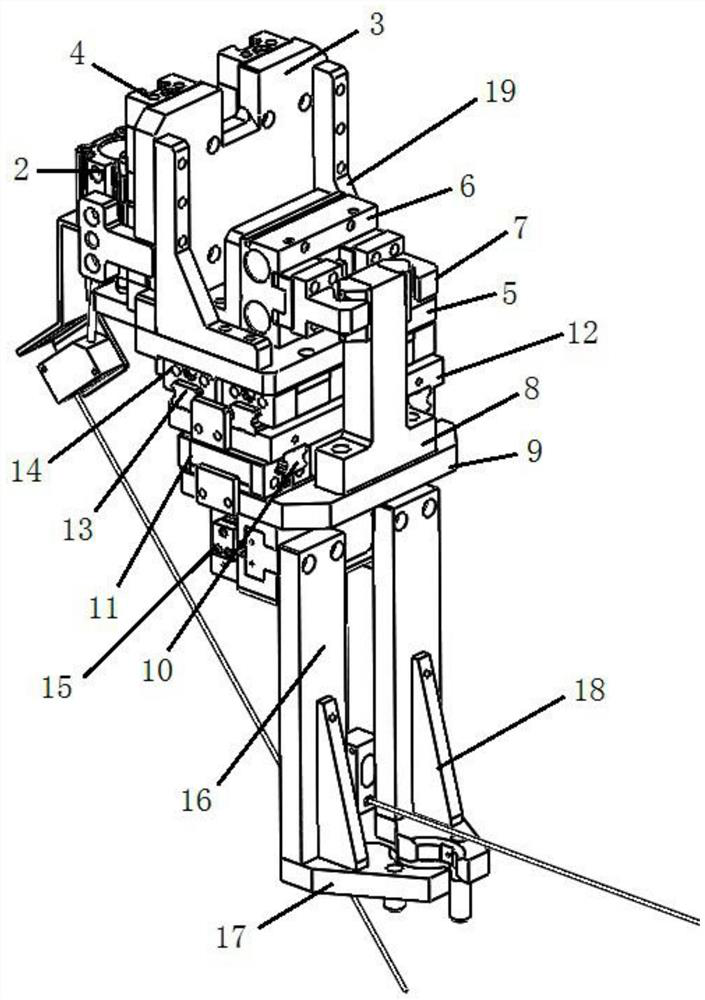

[0014] Attached below Figure 1-2 The present invention is described further:

[0015] A workpiece grabbing device with a three-axis compensation mechanism, the connecting flange 1 is connected to the mechanism connecting plate 20, the Z-axis floating compensation cylinder 2 is connected to the mechanism connecting plate 20, and the output end of the Z-axis floating compensation cylinder 2 is connected to the slider a. The slider a is slidably connected to the guide rail a4 on the vertical plate 3, the bottom of the vertical plate 3 is connected to the upper plate 5, the upper plate 5 is provided with a clamping cylinder a6, and the clamping cylinder a6 is connected to two opposing jaws 7, T The top of the T-shaped connector 8 is located between the two jaws 7, and the T-shaped connector 8 is connected to the lower plate 9. The lower plate 9 is provided with a slider b11 that is slidably connected to the guide rail b10, and the guide rail b10 is located on the middle plate. 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap