A full-suction turning mechanism and the printing device composed of it

A wind-type, air-absorbing board technology, applied in printing devices, printing, typewriters, etc., can solve the problems of unsuitable industrial printing, slow double-sided printing, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

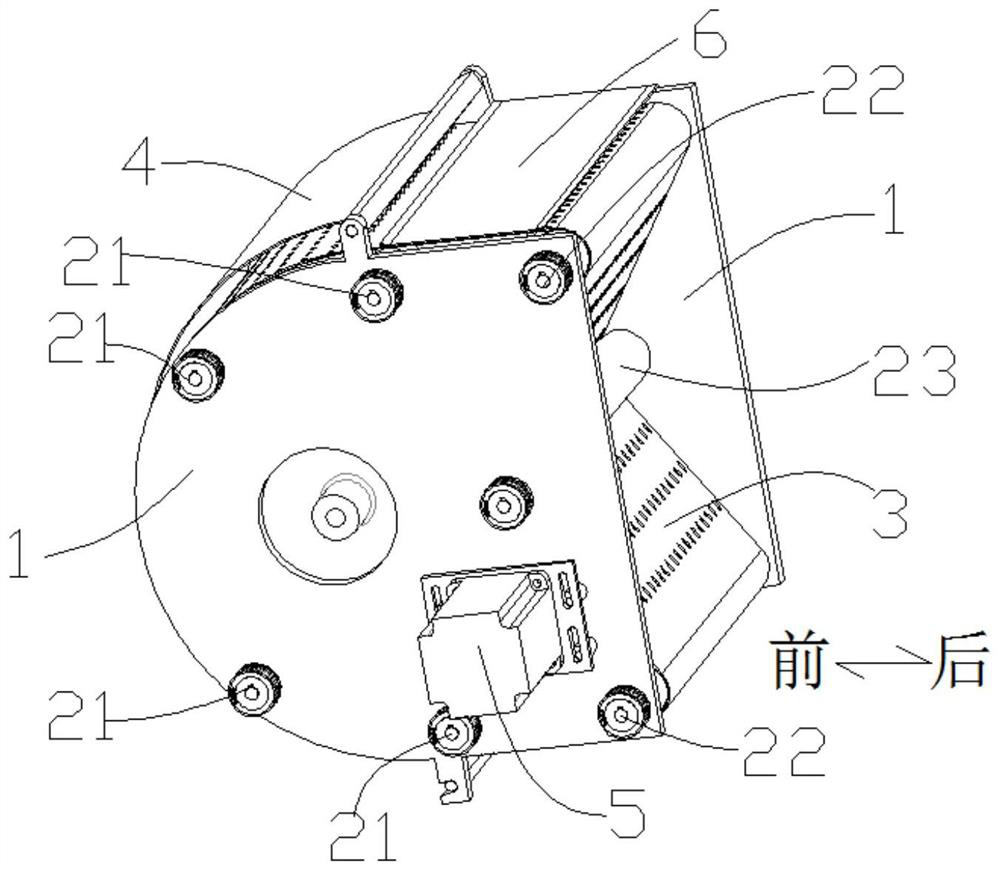

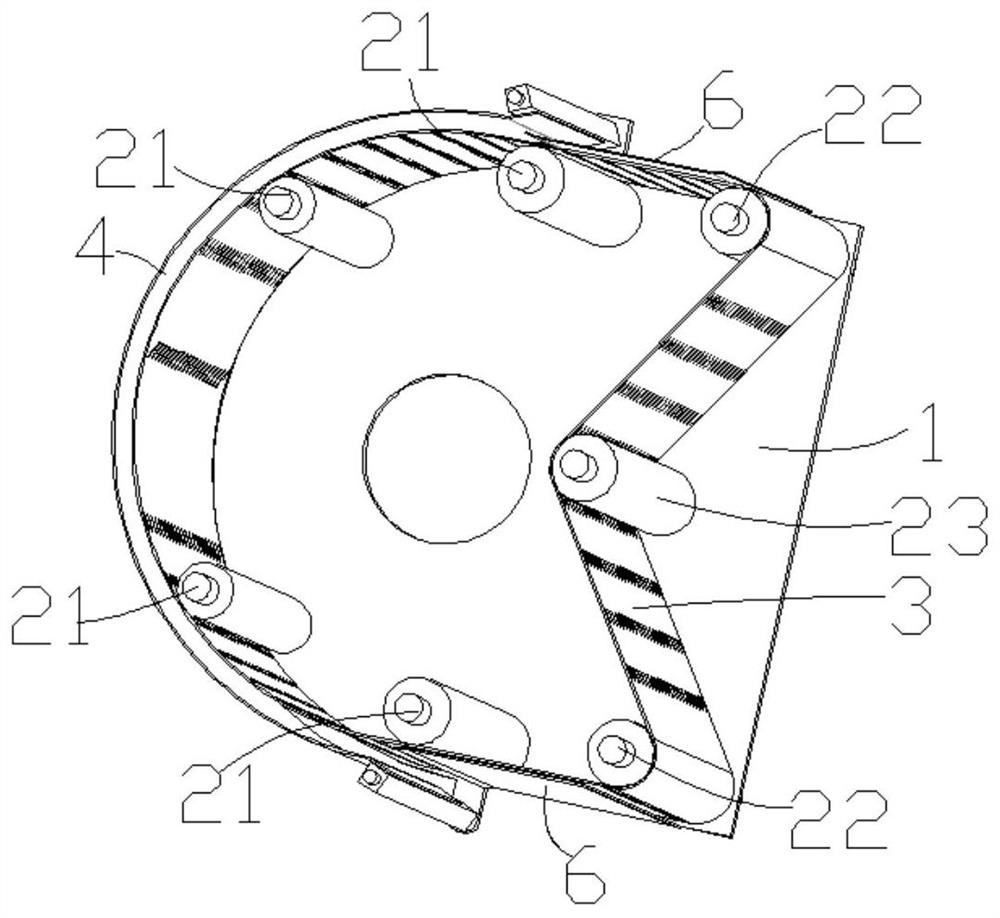

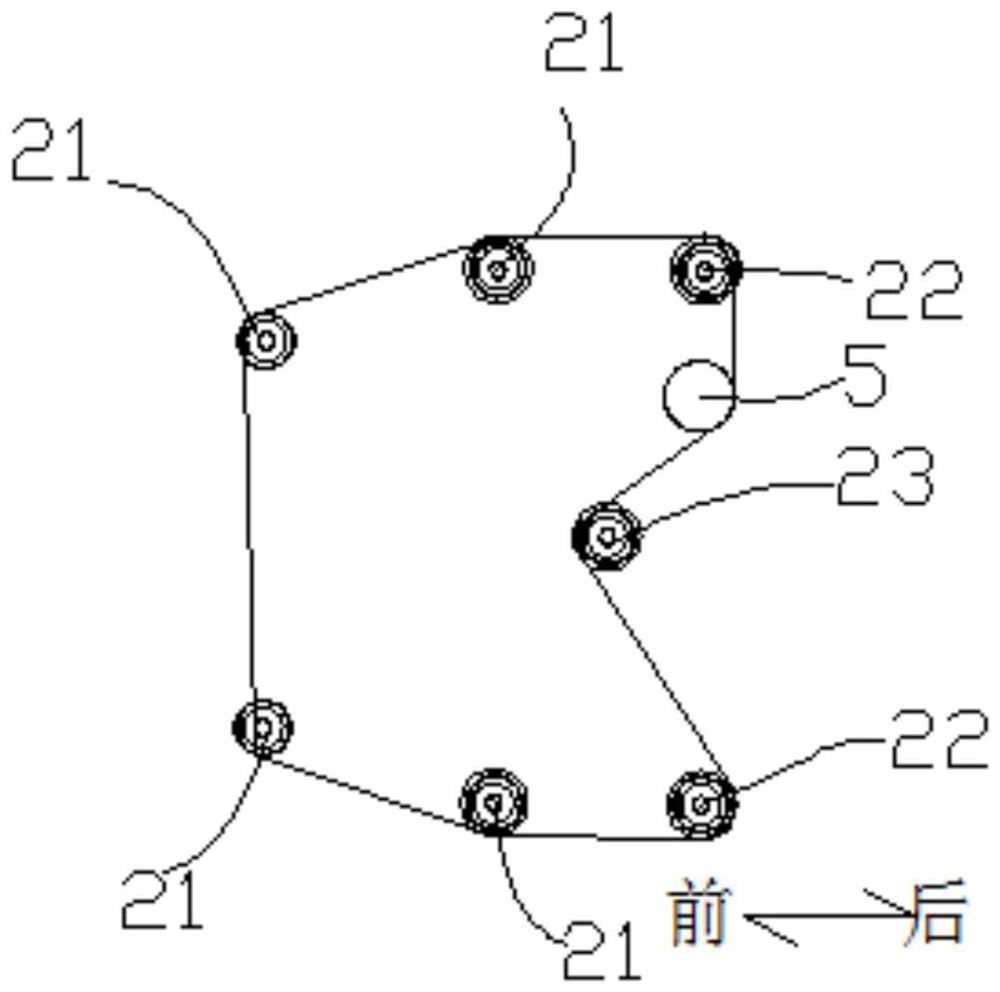

Image

Examples

Embodiment 2

[0035] With embodiment 1, its difference is, as Figure 4-Figure 6 As shown, the above technical solution also includes a casing 7, the casing 7 is arranged in the loop of the conveyor belt 3, and is located in the arc panel 4, the front side of the casing 7 is an arc surface , and the arc surface of the housing 7 is correspondingly provided with a plurality of notches 71 horizontally distributed along the left and right directions and matching with the first roller 21, the front side of the housing 7 is in contact with the conveyor belt 3 fit, and each of the gaps 71 is extended into a first roller 21, the arc surface of the housing 7 is covered with small holes passing through it, and the left and right sides of the housing 7 are It is connected with the two support plates 1, and the interface on the support plate 1 is extended to communicate with the inside of the housing 7, so that the negative pressure adsorption effect of the paper at the position of the arc plate pair i...

Embodiment 3

[0040] This embodiment provides a printing device using a full-suction turning mechanism as in Embodiment 1 or 2, which has a fast turning speed and high printing efficiency. Wherein, the printing device may be a jet printing device or a printing device, and the jet printing device may have a structure similar to that disclosed in CN109334275B, and the full suction type turning mechanism disclosed in Embodiment 2 replaces the one in the document Just turn over the mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com