Automatic overlapping machine for manufacturing honeycomb materials

A honeycomb material and automatic technology, applied in the field of machinery, can solve the problems of poor product quality, high labor intensity, low efficiency, etc., and achieve the effect of low cost, good product quality and guaranteed stacking position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

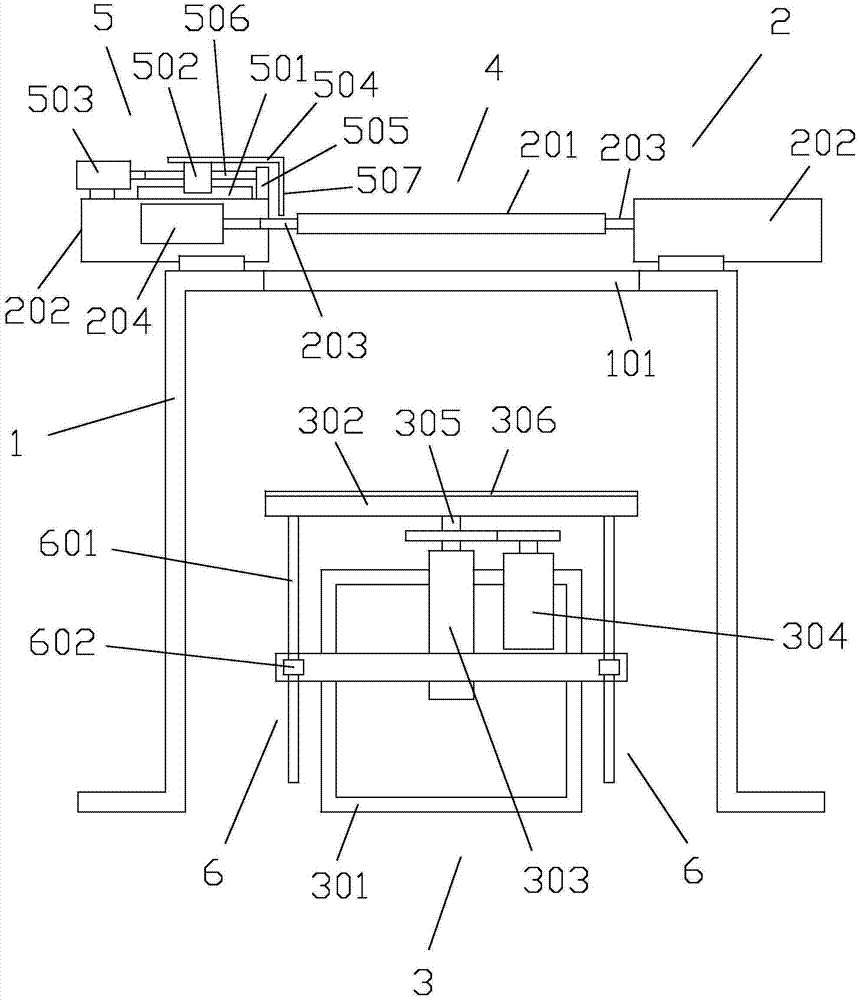

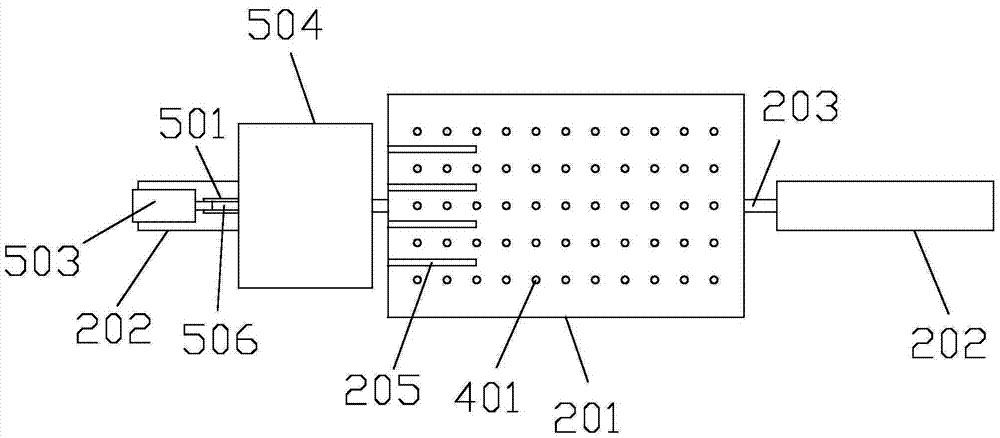

[0026] This is an automatic laminating machine used to make honeycomb materials, such as Figure 1 to 3 As shown, the frame 1 is included. The upper part of the frame 1 is equipped with an overturning and stacking device 2 and the lifting and stacking device 3 is installed under the overturning and stacking device 2.

[0027] An opening 101 is provided in the center of the upper part of the frame 1.

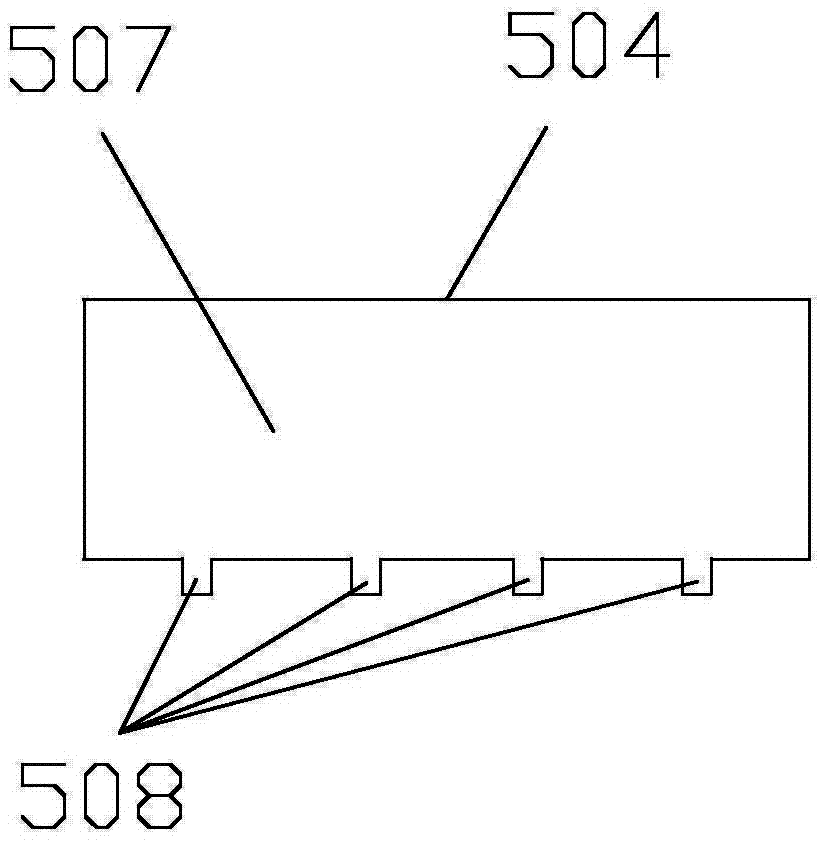

[0028] The turning and stacking device 2 includes a turning board 201, two mounting seats 202, the turning board 201 is installed between the two mounting seats 202, the turning board 201 is located above the opening 101 of the frame 1, and the turning board 201 is horizontally arranged on both sides of the rotating shaft 203 is rotatably mounted on the corresponding mounting base 202. The mounting base 202 is equipped with a turning motor 204. The turning motor 204 turns the turning plate 201 through the driving shaft 203. The turning plate 201 is provided with a fixing device for fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com