Blister tray separating mechanism

A technology of blister trays and trays, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of lack of Tray tray positioning structure, poor separation effect, and single suction cup grabbing Tray trays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

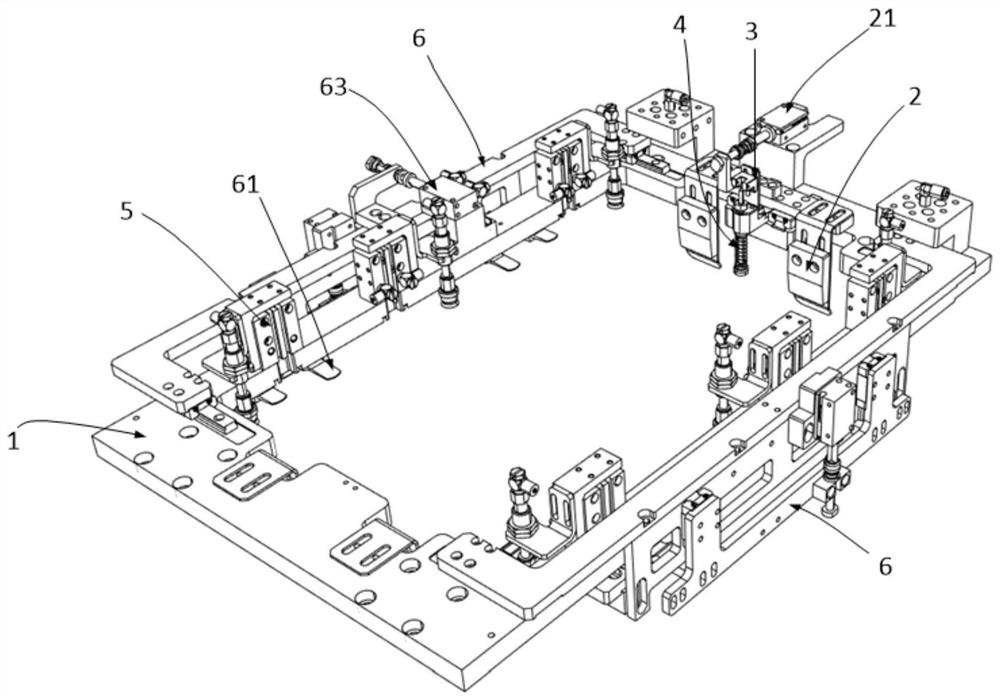

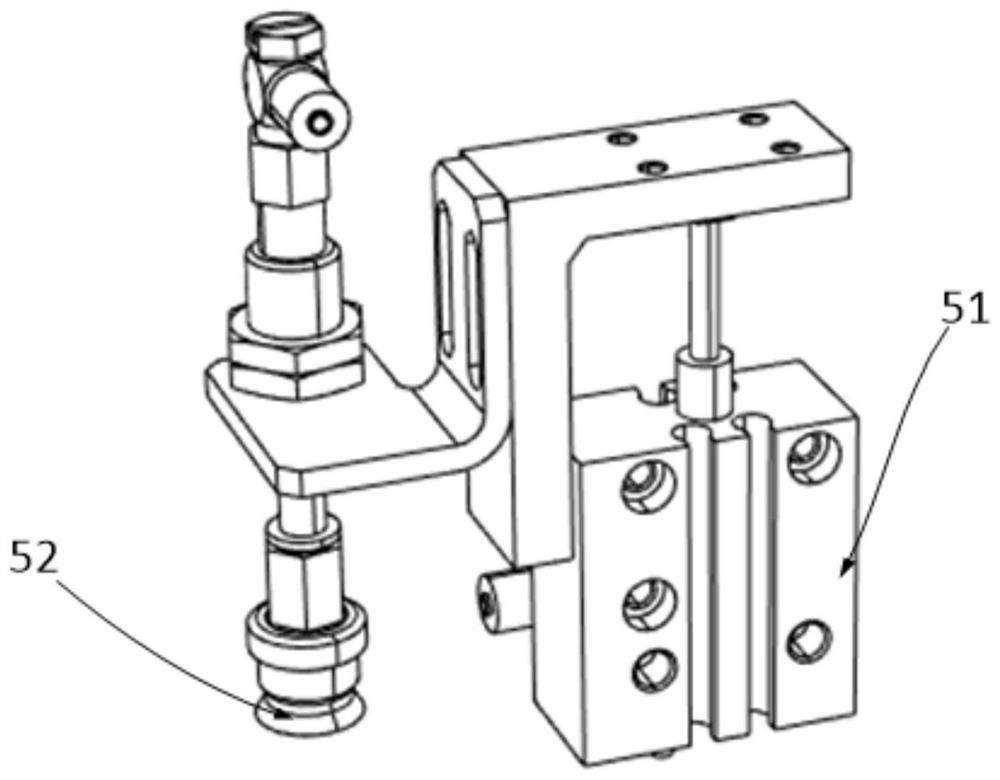

[0062] The present embodiment provides a kind of suction plastic disc dividing mechanism, such as Figure 1-4 shown, including:

[0063] Frame 1, the middle of the frame 1 has a square passage opening through which the feeding tray passes;

[0064] The positioning block 2 is installed on both sides of the frame 1 parallel to the X-axis direction, at least one of the positioning blocks 2 on both sides is connected with a first positioning cylinder 21, and the pushing direction of the first positioning cylinder 21 is Along the Y axis and push towards the inside of the frame 1;

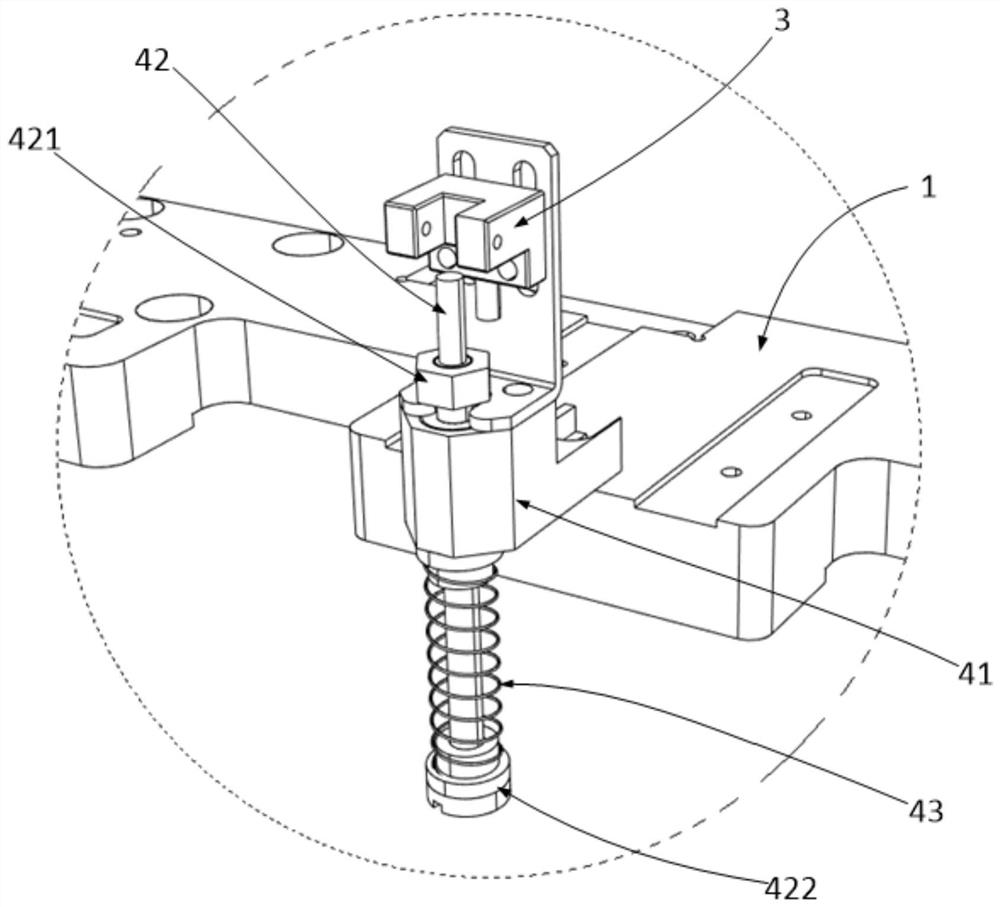

[0065] The sensor assembly 3 is fixed on the edge of the frame 1 and is located above the square passage opening for sensing the telescopic rod 42;

[0066] The gear lever assembly 4 is arranged on the edge of the frame 1, and includes a fixed seat 41 fixed on the frame 1, a telescopic rod 42 and a return spring 43 arranged along the Z axis, and the telescopic rod 42 is installed on the fixed seat 41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com