A kind of frp bar with reserved bending point and its manufacturing method

A manufacturing method and bending point technology, applied in construction, building reinforcements, building components, etc., can solve problems such as corrosion durability of steel elbows, and achieve the effect of solving corrosion problems and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

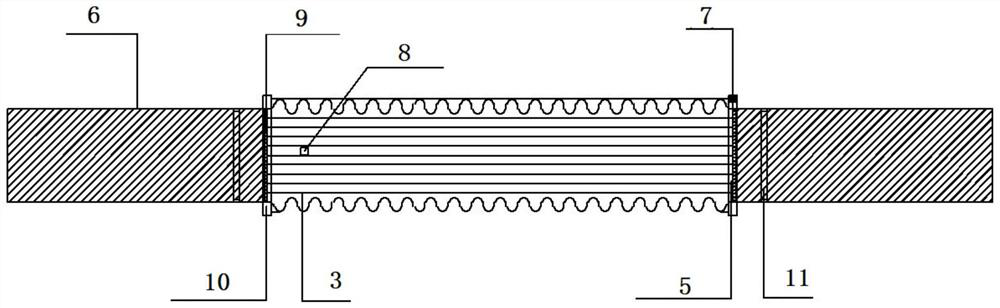

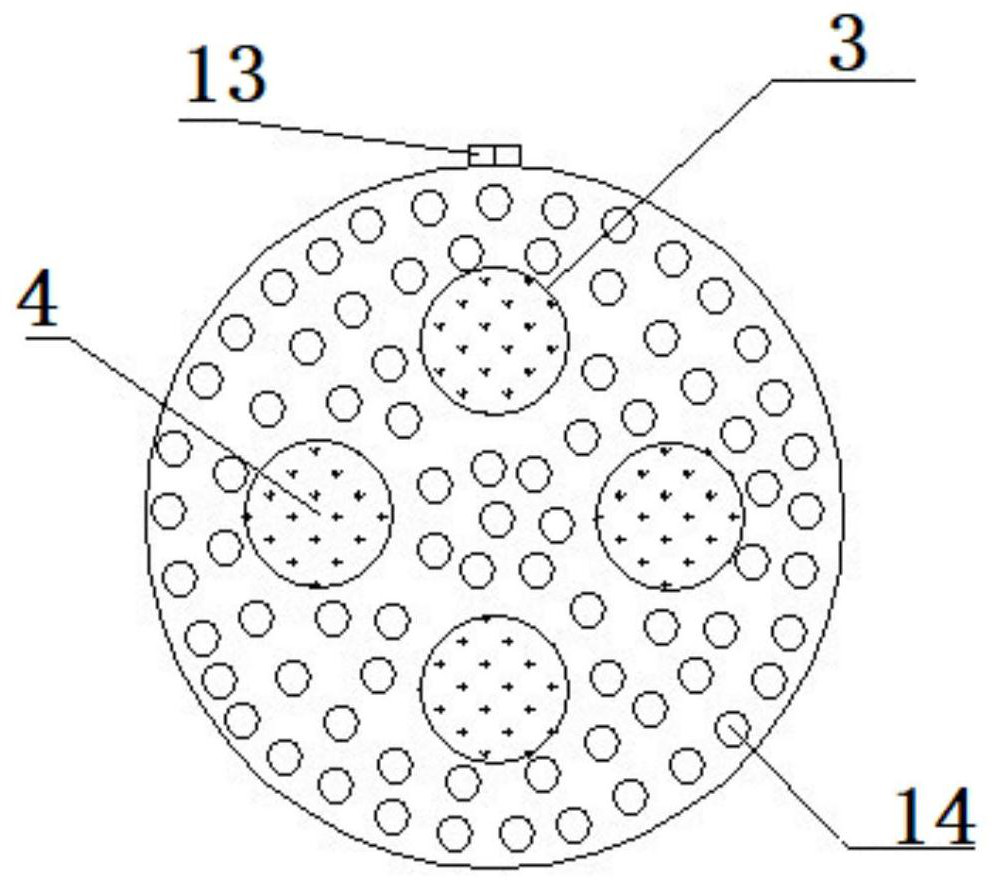

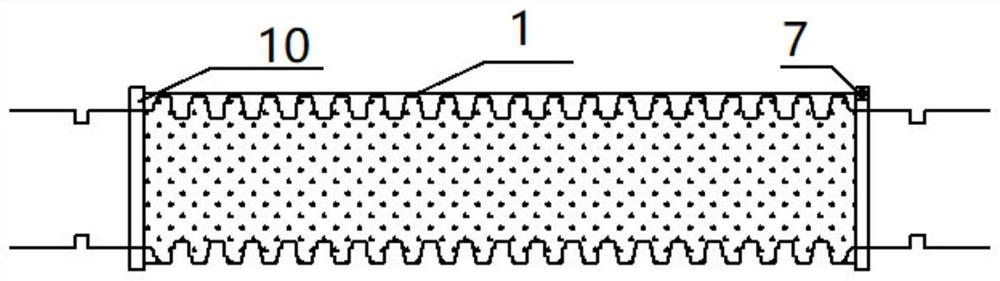

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] see Figure 1 to Figure 10 , an FRP bar with reserved bending points, including a corrugated tube 1, the two ends of the corrugated tube 1 are fixed on the curing section 6, a zipper structure 2 is arranged on the axial surface of the corrugated tube 1 along the axial direction, and the zipper structure 2 Concave-convex buttons 13 are arranged on the top, and a porous ring 5 is arranged in the bellows 1, and the porous ring 5 is fixed on the slider 7. A plurality of carbon fiber tubes 3 are arranged in the bellows 1 along the axial direction, and the spaces between the carbon fiber tubes 3 are filled with Fiber 14, carbon fiber tube 3 is filled with curing agent 4, the inner wall of bellows 1 is coated with epoxy resin, and the inside of bellows 1 is filled with epoxy resin after sealing. The concave-convex buckle 13 is provided with a slider 7 . The bellows 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com