Acceleration sensor and electronic equipment

An acceleration sensor and density technology, applied in the field of sensors, can solve the problems of large chip area and high production cost, and achieve the effects of reducing chip area, miniaturization, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the application with reference to the drawings in the embodiments of the application. Apparently, the described embodiments are only some, not all, embodiments of the application.

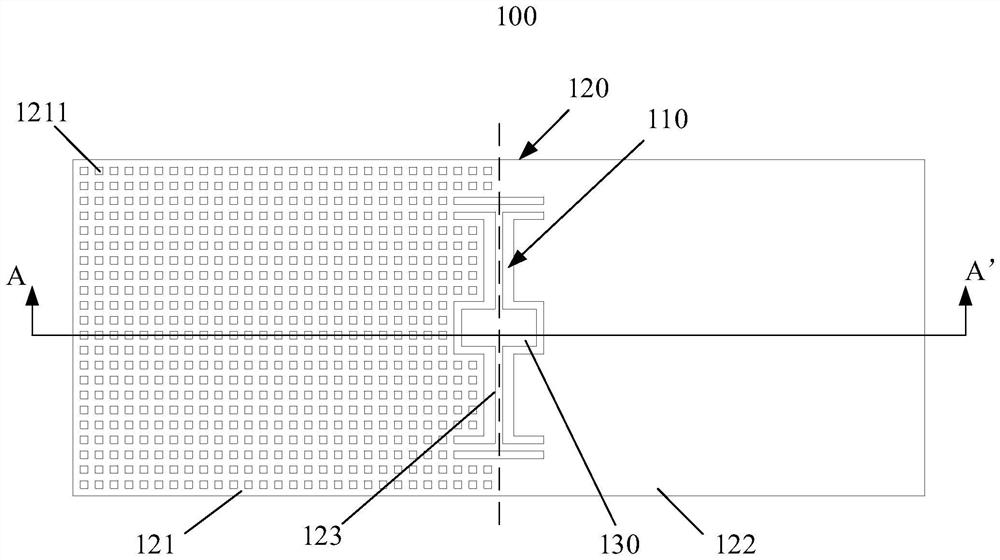

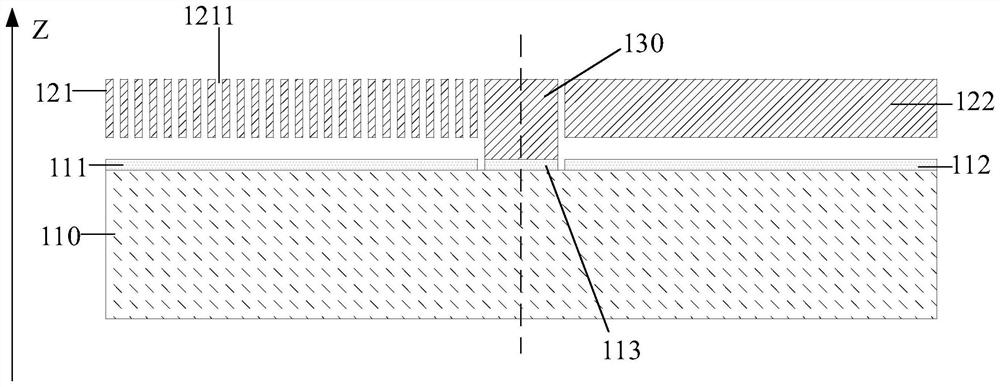

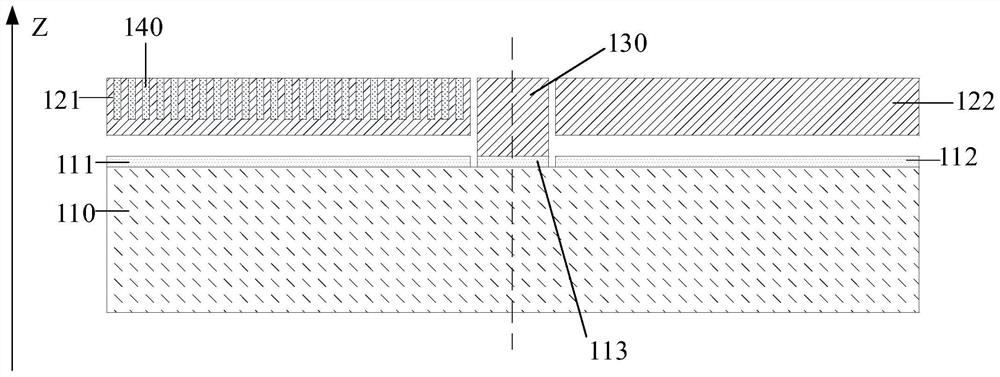

[0025] Existing acceleration sensors generally have the problems of large chip area and high manufacturing cost, especially Z-axis acceleration sensors. A general Z-axis acceleration sensor is provided with a beam, and the two sides of the beam are two parts with the same material but different areas, and the distances from the center of mass of the two parts to the beam are not equal. Using the eccentric mass of one part can cause the two parts to twist about the beam, and based on the twist of the two parts, the acceleration in the Z axis can be detected. This kind of acceleration sensor usually has a large chip area, and due to the asymmetry of the two parts with different areas on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com