A metal fitting for power lines

A technology for power lines and fittings, applied in the field of fittings, can solve problems such as time-consuming and labor-intensive, and achieve the effects of easy use, firm locking, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

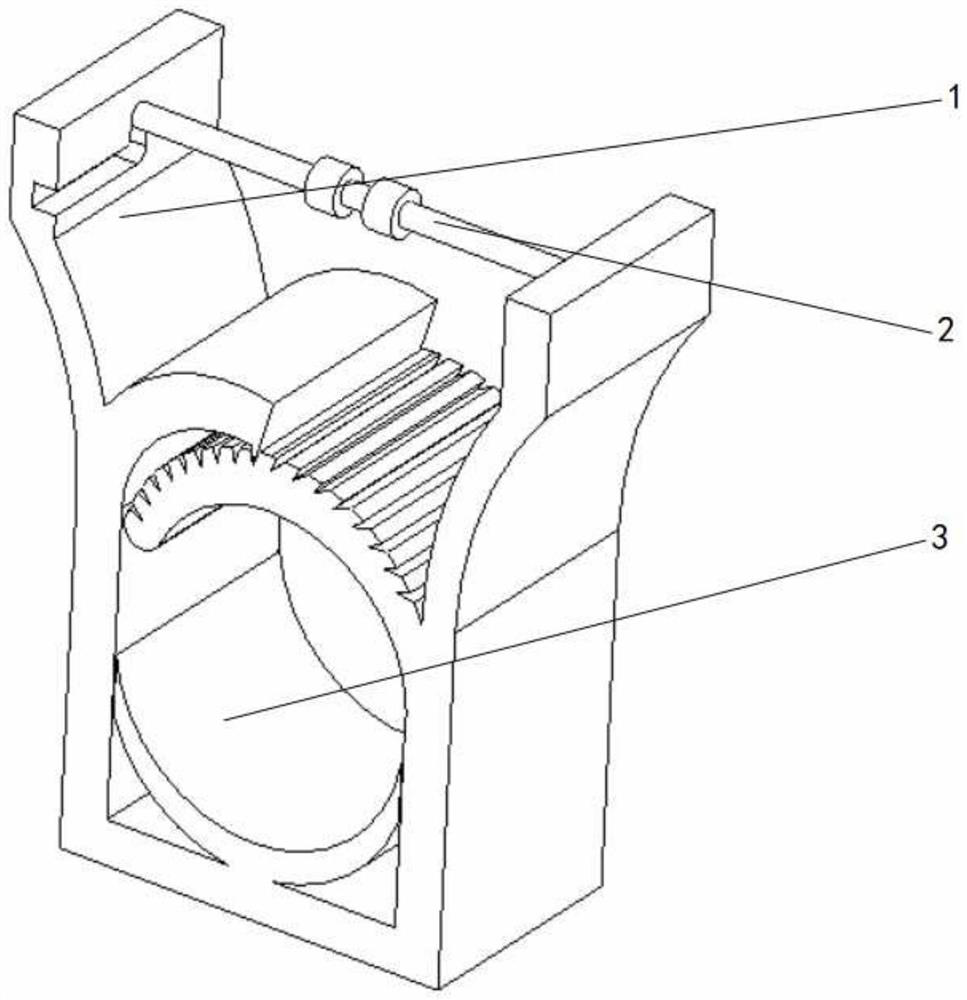

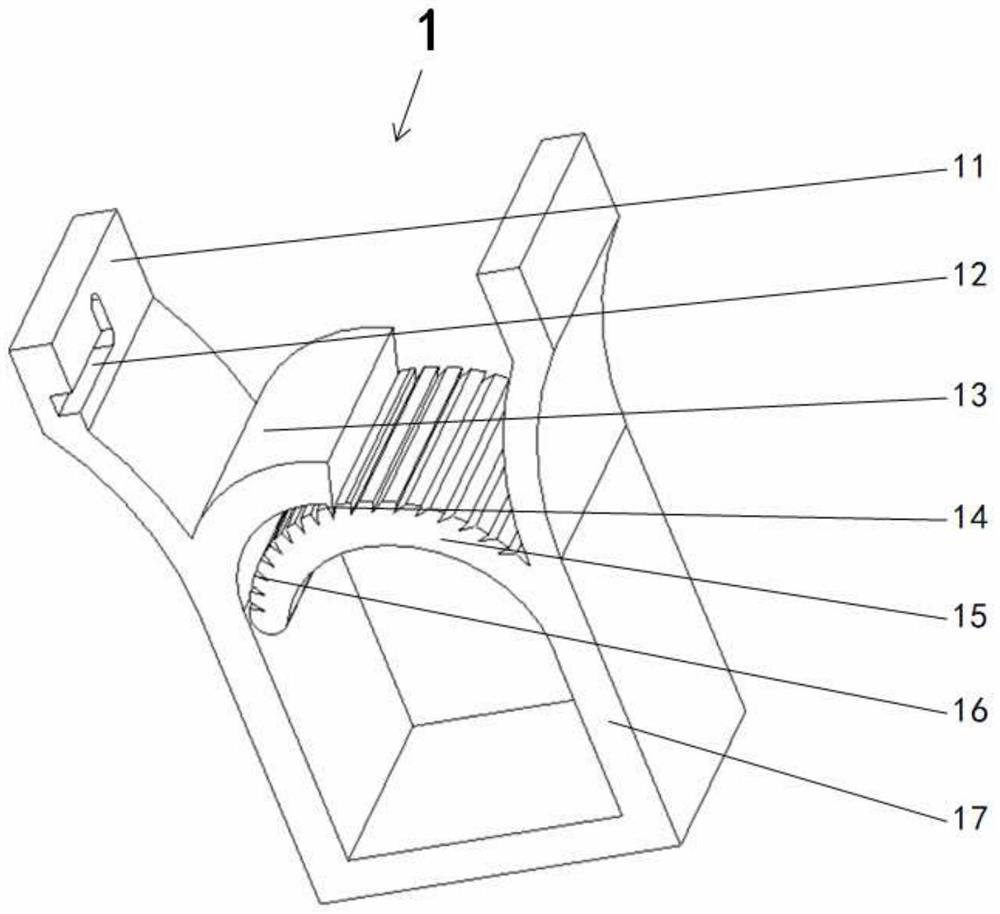

[0033] please see Figure 1 to Figure 4 , a metal fitting for a power line, having a fitting main body 1, characterized in that the fitting main body 1 is composed of a U-shaped wall body 17 and extrusion parts 11 located at both ends of the U-shaped wall body 17, and the U-shaped wall body 17 has two The end is bent to the outside, and the inner wall on the left side of the U-shaped wall body 17 is provided with a first buckle body 13 inwardly, and a locking tooth 14 is arranged below the end of the first buckle body 13, and the inner side of the right side of the U-shaped wall body 17 The wall is provided with an upwardly curved arc-shaped second buckle main body 15 inwardly, and a plurality of buckle grooves 16 are formed along the upper surface of the second buckle main body 15, and the first buckle main body 13 presses the second buckle main body 15 against the Below, the locking tooth 14 is locked in the locking groove 16, the tooth tip of the locking tooth 14 and the lo...

Embodiment 2

[0035]A kind of fittings for power lines, which has a fittings main body 1, characterized in that the fittings main body 1 is composed of a U-shaped wall body 17, extrusion parts 11 located at both ends of the U-shaped wall body 17, and the two ends of the U-shaped wall body 17 Bending outwards, the inner side wall on the left side of the U-shaped wall body 17 is provided with a first buckle body 13 inwardly, and a locking tooth 14 is arranged below the end of the first buckle body 13, and the inner side wall on the right side of the U-shaped wall body 17 An upwardly curved arc-shaped second buckle body 15 is provided inwardly, and a plurality of buckle grooves 16 are formed along the upper surface of the second buckle body 15, and the first buckle body 13 presses the second buckle body 15 below , the locking tooth 14 is stuck in the slot 16, the tip of the locking tooth 14 and the slot 16 and the tip of the slot face to the left, the first buckle main body 13 and the second bu...

Embodiment 3

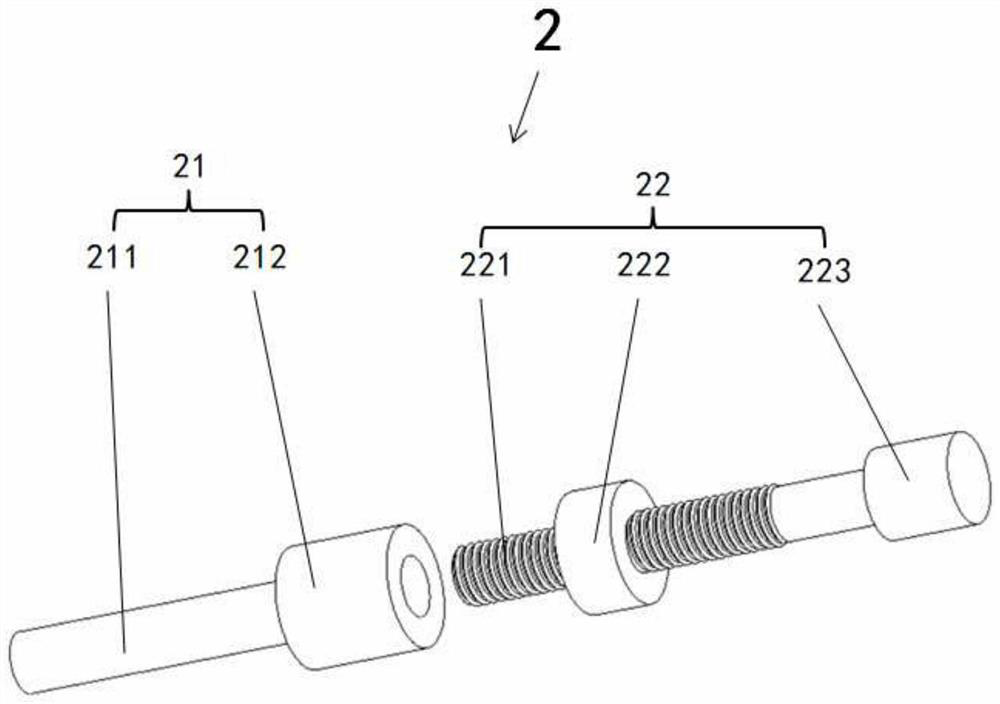

[0038] please see Figure 4 to Figure 7 , a metal fitting for a power line, having a fitting main body 1, characterized in that the fitting main body 1 is composed of a U-shaped wall body 17 and extrusion parts 11 located at both ends of the U-shaped wall body 17, and the U-shaped wall body 17 has two The end is bent to the outside, and the inner wall on the left side of the U-shaped wall body 17 is provided with a first buckle body 13 inwardly, and a locking tooth 14 is arranged below the end of the first buckle body 13, and the inner side of the right side of the U-shaped wall body 17 The wall is provided with an upwardly curved arc-shaped second buckle main body 15 inwardly, and a plurality of buckle grooves 16 are formed along the upper surface of the second buckle main body 15, and the first buckle main body 13 presses the second buckle main body 15 against the Below, the locking tooth 14 is locked in the locking groove 16, the tooth tip of the locking tooth 14 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com