Rotary yoke magnetic circuit structure

A yoke and magnetic circuit technology, applied in the field of the magnetic circuit structure of the rotating yoke, can solve the problems of reduced speed regulation efficiency and increased iron loss, and achieve the effects of improving efficiency, improving efficiency and high magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

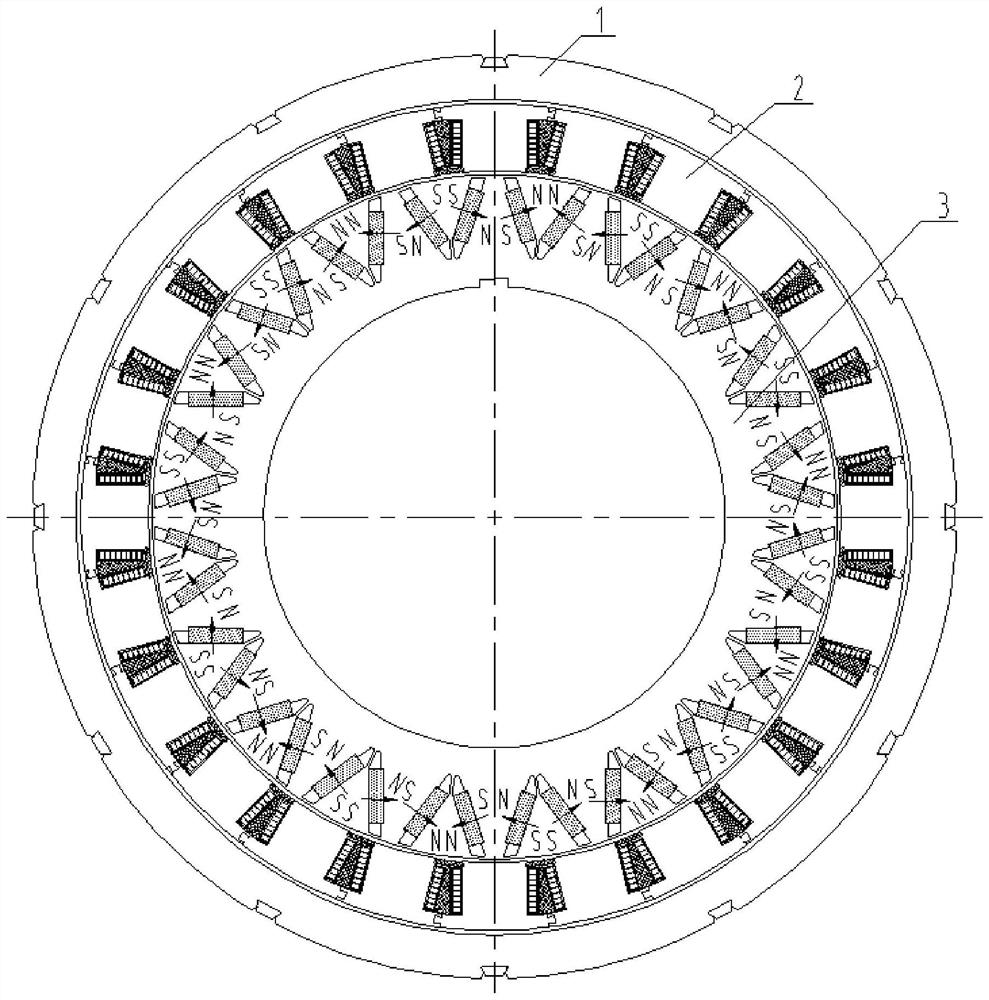

[0038] The magnetic circuit structure of the rotary yoke provided by this embodiment, such as figure 1 As shown, it includes a permanent magnet rotor and a winding rotor; the permanent magnet rotor includes: an inner permanent magnet rotor 3 and an outer rotor yoke 1; the outer rotor yoke 1 and the inner permanent magnet rotor 3 are rigidly connected, rotate synchronously, and have no speed Difference. The permanent magnetic flux starts from one magnetic pole, enters the nearest winding rotor tooth through the air gap, then bypasses the winding rotor winding through the outer rotor yoke, and returns to the original two adjacent magnetization through the adjacent tooth. Magnetic poles in different directions. The permanent magnet rotor rotates around the center, and the permanent magnet magnetic field remains unchanged or changes very little, so iron loss is not easy to occur, and the efficiency is improved.

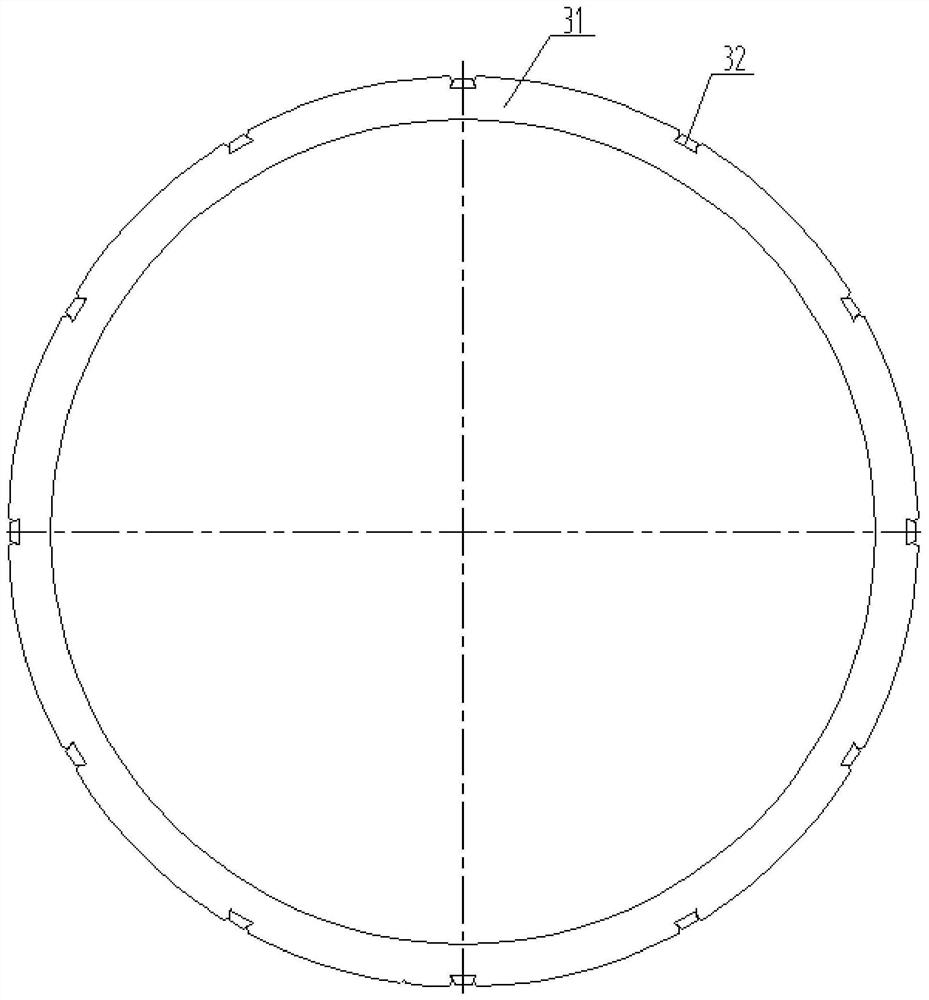

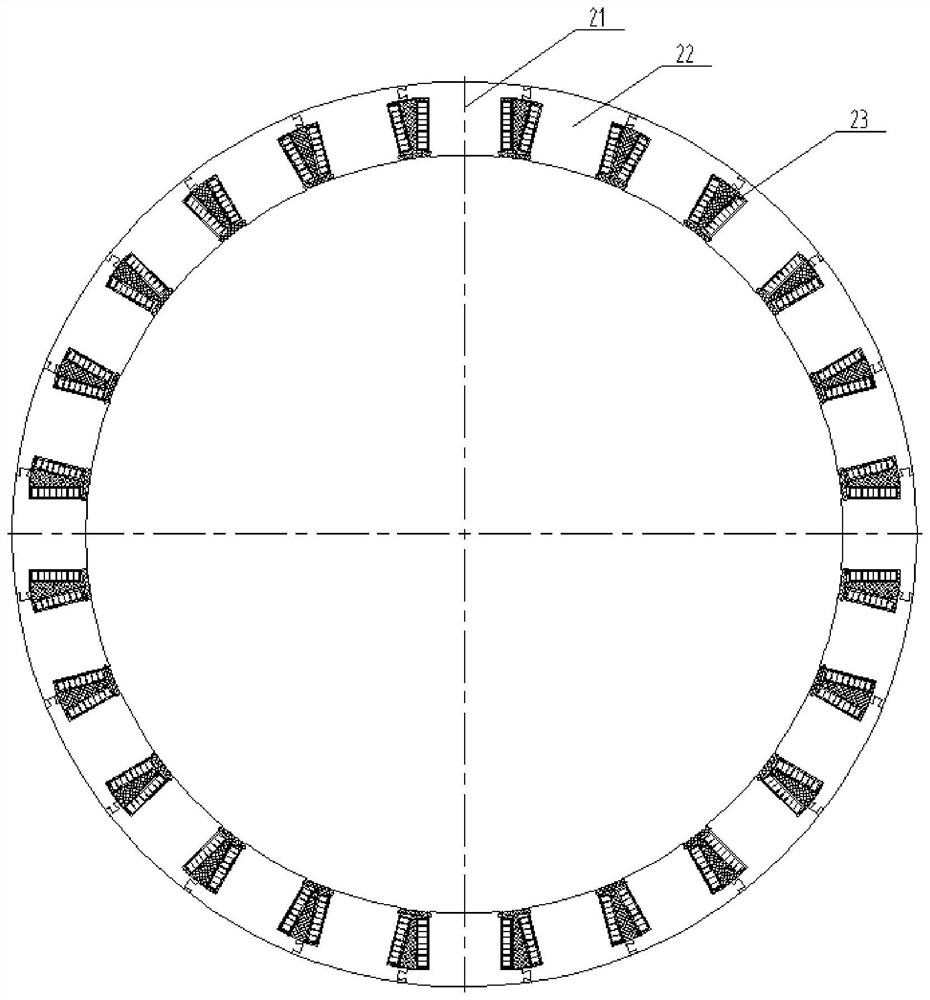

[0039] Such as figure 2 Shown is the outer rotor yoke structure....

Embodiment 2

[0046] The magnetic circuit structure of the rotating yoke provided by Embodiment 2, such as Figure 6 As shown, it includes a permanent magnet rotor and a winding rotor 2. The permanent magnet rotor includes an inner rotor yoke 4 and an outer permanent magnet rotor 5; the outer permanent magnet rotor 5 and the inner rotor yoke 4 are rigidly connected, rotate synchronously, and have no speed difference . The permanent magnetic flux starts from one magnetic pole, enters the nearest winding rotor tooth through the air gap, then bypasses the winding rotor winding through the outer rotor yoke, and returns to the original two adjacent magnetization through the adjacent tooth. Magnetic poles in different directions. The permanent magnet rotor rotates around the center, and the permanent magnet magnetic field remains unchanged or changes very little, so iron loss is not easy to occur, and the efficiency is improved.

[0047] The inner rotor yoke 4 is formed by laminating the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com