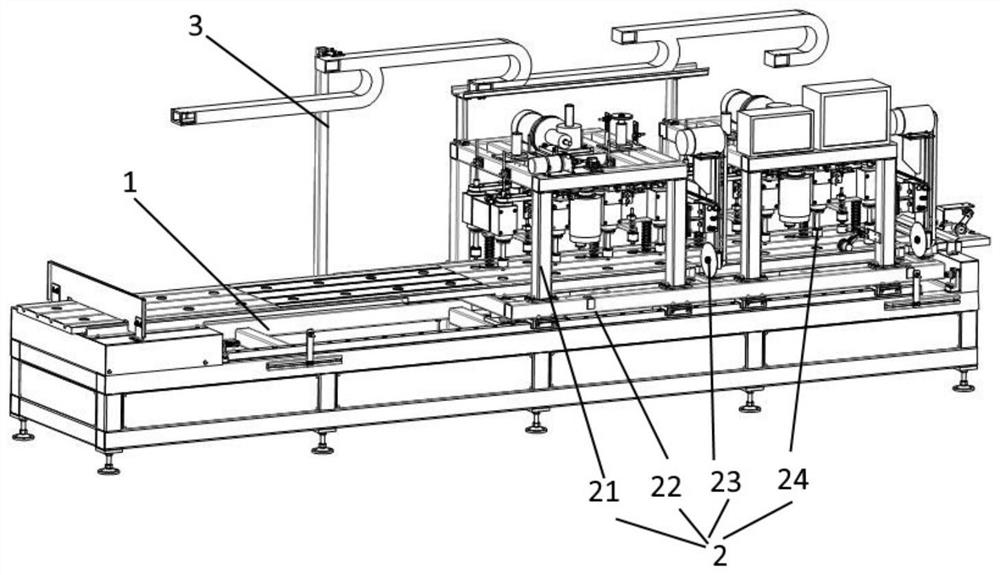

Punching device for floor heating insulation board and punching method of punching device

A punching device and insulation board technology, which is applied in metal processing and other directions, can solve the problems of manual punching, insulation board falling off, low work efficiency, etc., and achieve the effect of increased punching rate and beautiful holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

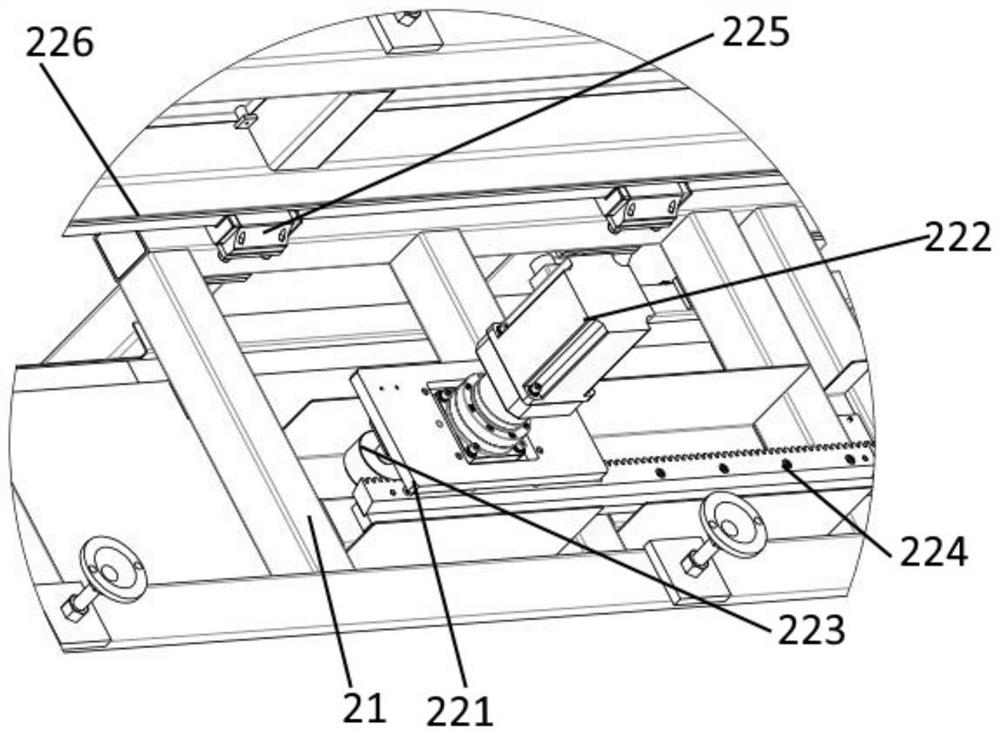

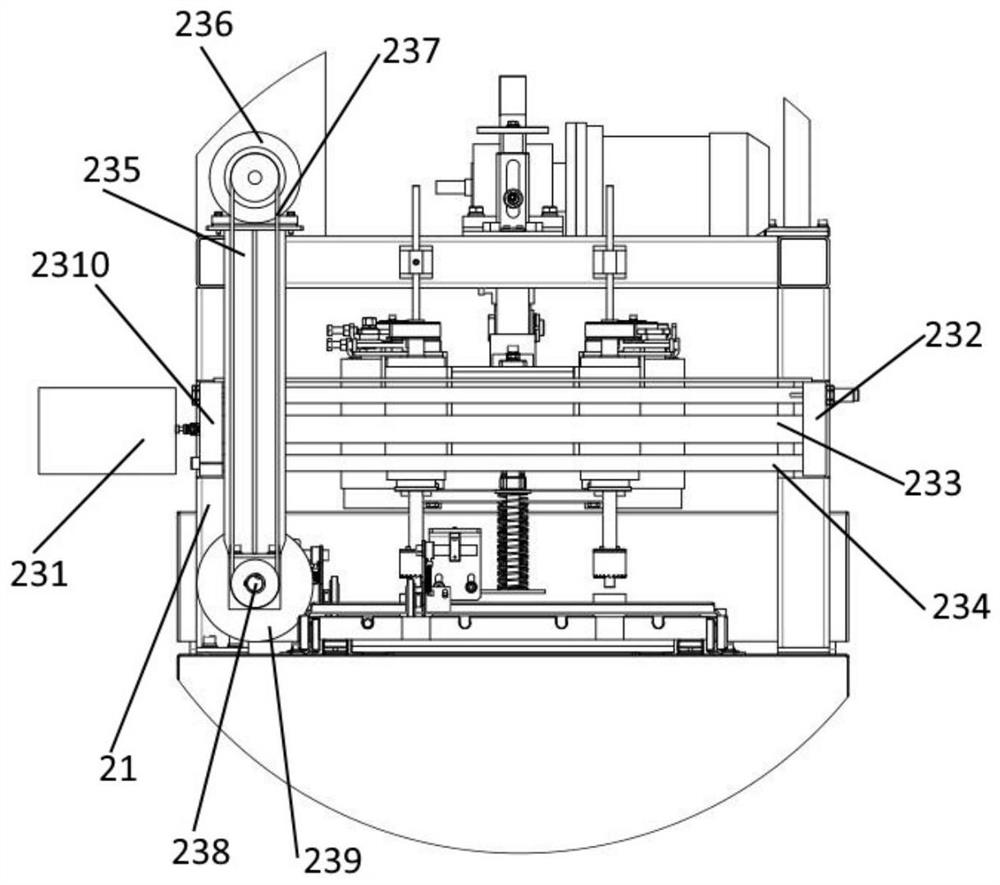

Embodiment Construction

[0040] After the applicant's research and analysis, the reason for this problem (after the floor heating pipe is used for a long time, the deformation between the insulation plate and the aluminum plate or the heat conduction plate is too large, which will cause the insulation plate to fall off) is that the existing Most of the thermal insulation boards spray glue between the aluminum plate and the thermal insulation board, and then complete the connection between the aluminum plate and the thermal insulation board by gluing, but because the thermal expansion coefficient between the thermal insulation board and the heat conduction After the tube has been used for a long time, the deformation between the insulation board and the aluminum plate or the heat conduction plate is too large. In order to avoid the deformation of the insulation board, some enterprises have set round holes on the insulation board. A certain deformation space is reserved to avoid damage to the insulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com