Dispensing devices and laundry handling equipment

A technology for clothes processing equipment and feeding devices, which is applied in washing devices, other washing machines, textiles and papermaking, etc., and can solve problems such as complex structure, inconvenient use, and expensive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

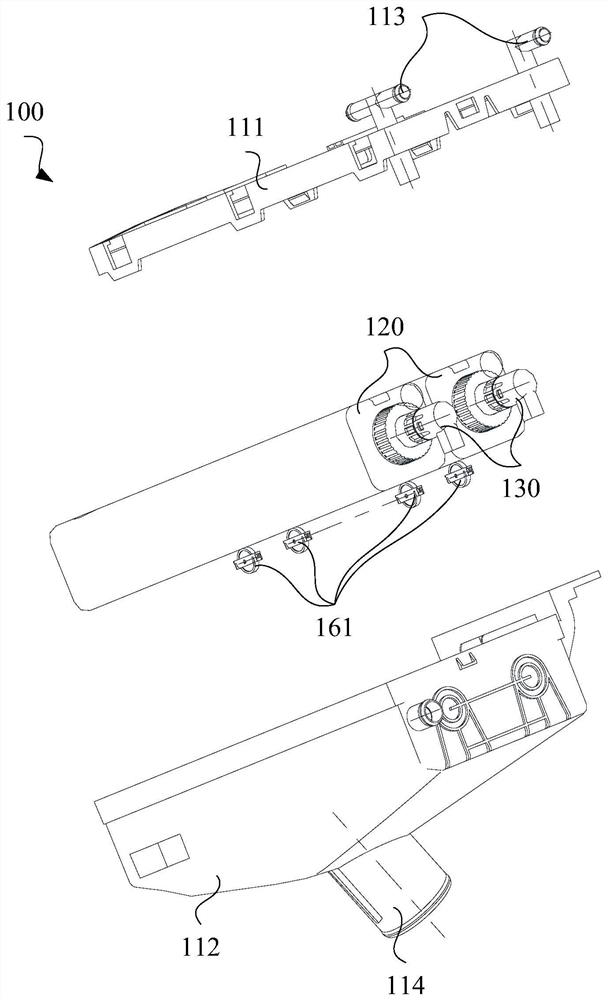

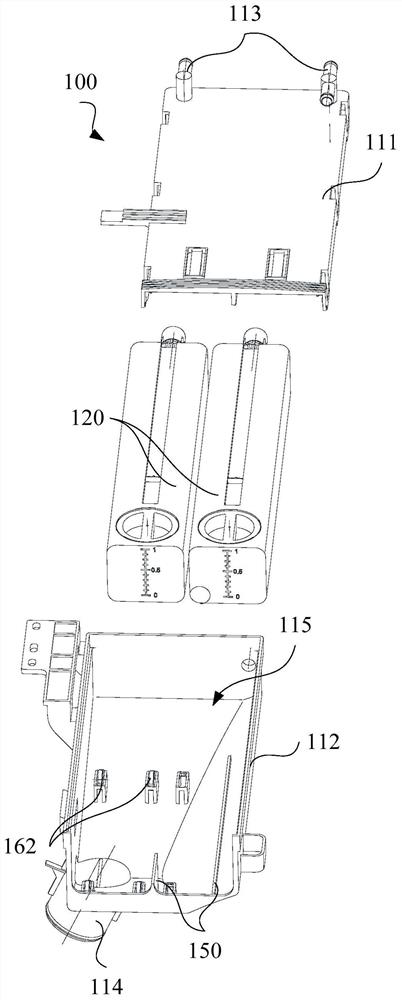

[0069] According to a first aspect of the present invention, a dispensing device 100 is provided, such as figure 1 , figure 2 , Figure 4 and Figure 8As shown, it includes a detergent box 110 , a liquid storage part 120 and a dispensing assembly 130 , and the liquid storage part 120 is detachably arranged in the detergent box 110 . The dispensing assembly 130 is arranged at the end of the liquid storage part 120 and is located in the detergent box 110. The liquid storage part 120 can drive at least a part of the dispensing assembly 130 to move relative to the detergent box 110, so as to guide the liquid from the liquid storage part 120 to be dispensed. The assembly 130 flows into the detergent box 110 .

[0070] The dispensing device 100 provided by the present invention includes a detergent box 110 , a liquid storage part 120 and a dispensing assembly 130 . Specifically, the detergent box 110 has an assembly port, and the assembly port can facilitate the installation an...

Embodiment 2

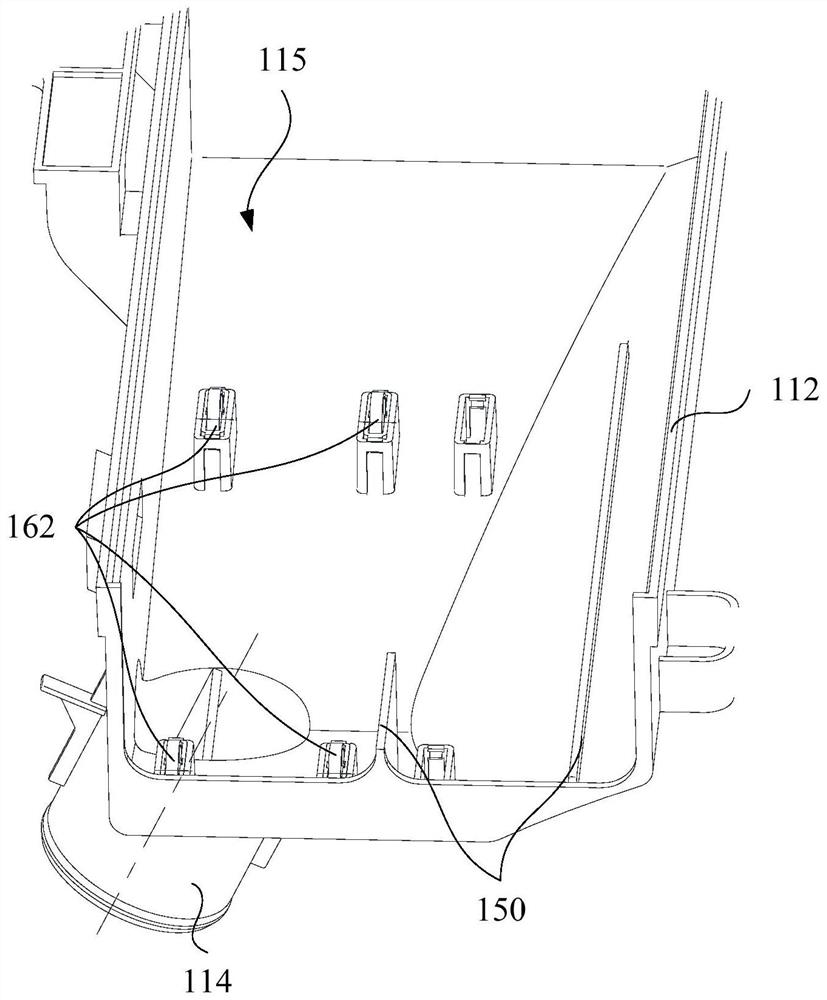

[0087] On the basis of the foregoing embodiments, this embodiment describes a cooperative structure of the detergent box 110 and the liquid storage part 120. Further, the dispensing device 100 also includes a first limiting part and a second limiting part. The limiting portion is disposed on the detergent box 110 . The second limiting portion is disposed on the liquid storage portion 120 , and the liquid storing portion 120 protrudes into the detergent box 110 so that the second limiting portion cooperates with the first limiting portion.

[0088] In this embodiment, the movement process between the liquid storage part 120 and the detergent box 110 is divided into two stages. The first stage includes that the liquid storage part 120 is assembled on the detergent box 110, or due to the addition of the liquid storage part 120 Liquid processing or replacement processing requires separating the liquid storage part 120 from the detergent box 110 , and the aforementioned two operati...

Embodiment 3

[0092] On the basis of the foregoing embodiments, this embodiment describes another cooperative structure of the detergent box 110 and the liquid storage part 120. Furthermore, the first limiting part and the second limiting part can be attracted by magnetic force to prevent the detergent box 110 from being stored. The liquid part 120 falls out of the detergent box 110 .

[0093]In this embodiment, when the liquid storage part 120 moves relative to the detergent box 110, that is, in the pressing stage, the user needs to overcome the gap between the first limiting part and the second limiting part when pressing the liquid storing part 120. The magnetic attraction force between them, so that the two are out of the mutual magnetic attraction range, will not interfere with the liquid conduction between the liquid storage part 120 and the dispensing assembly 130 . When the liquid storage part 120 resets under the active force, the distance between the first limiting part and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com