Heat insulation structure of gas turbine waste heat conveying pipeline

A technology for delivery pipes and gas turbines, which is applied to combustion engines, engine cooling, internal combustion piston engines, etc. It can solve problems such as inconvenience, waste heat damage of delivery pipes, inability to dissipate and absorb waste heat, and achieve the effect of preventing and avoiding heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

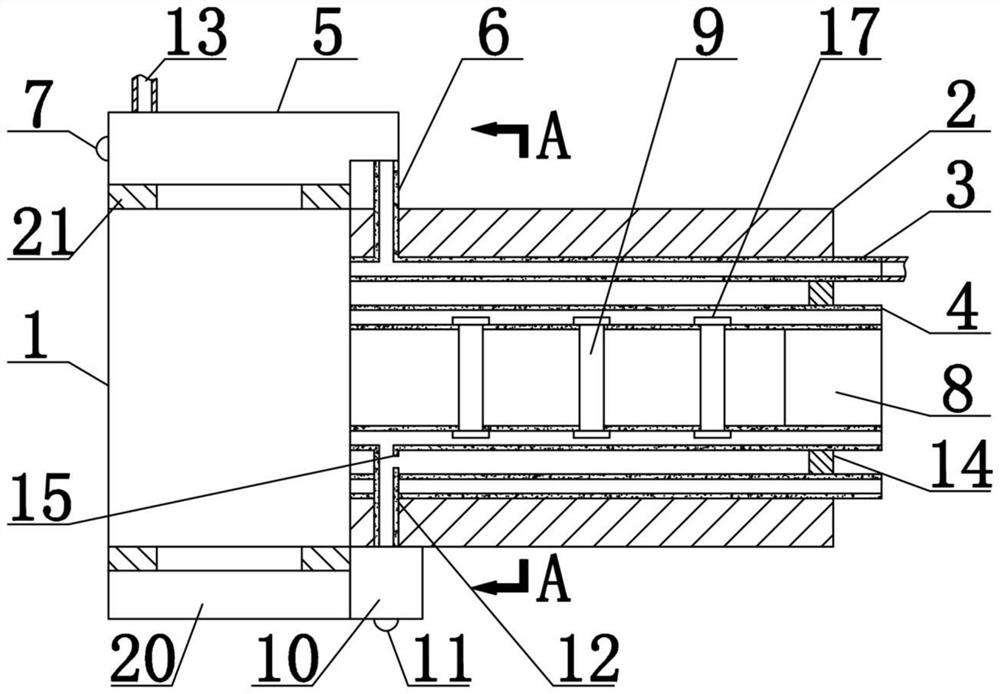

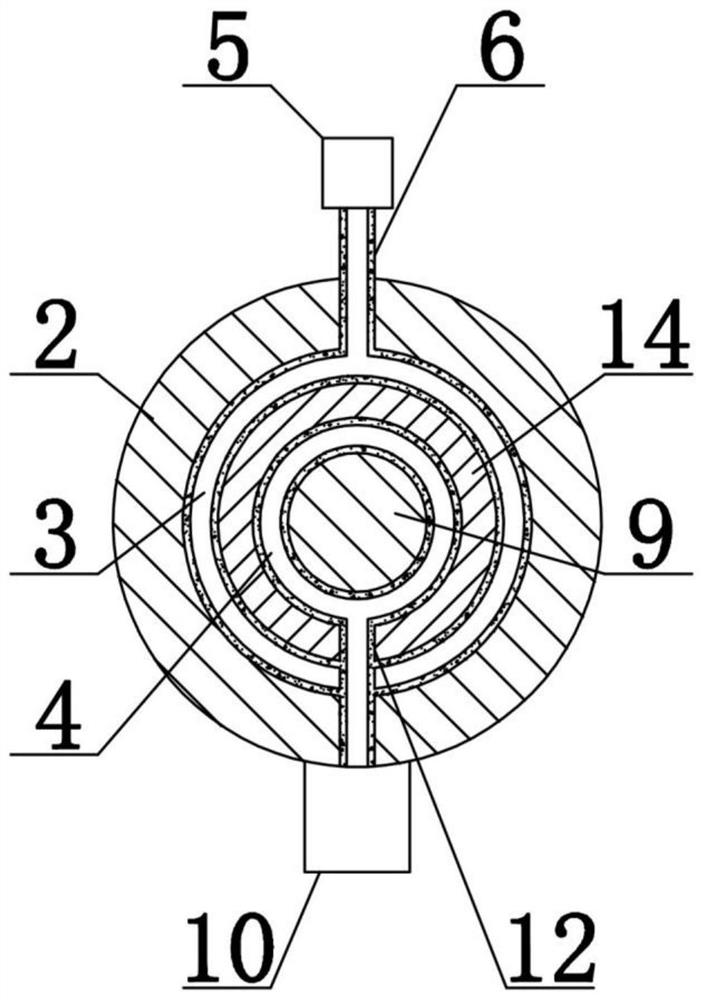

[0023] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

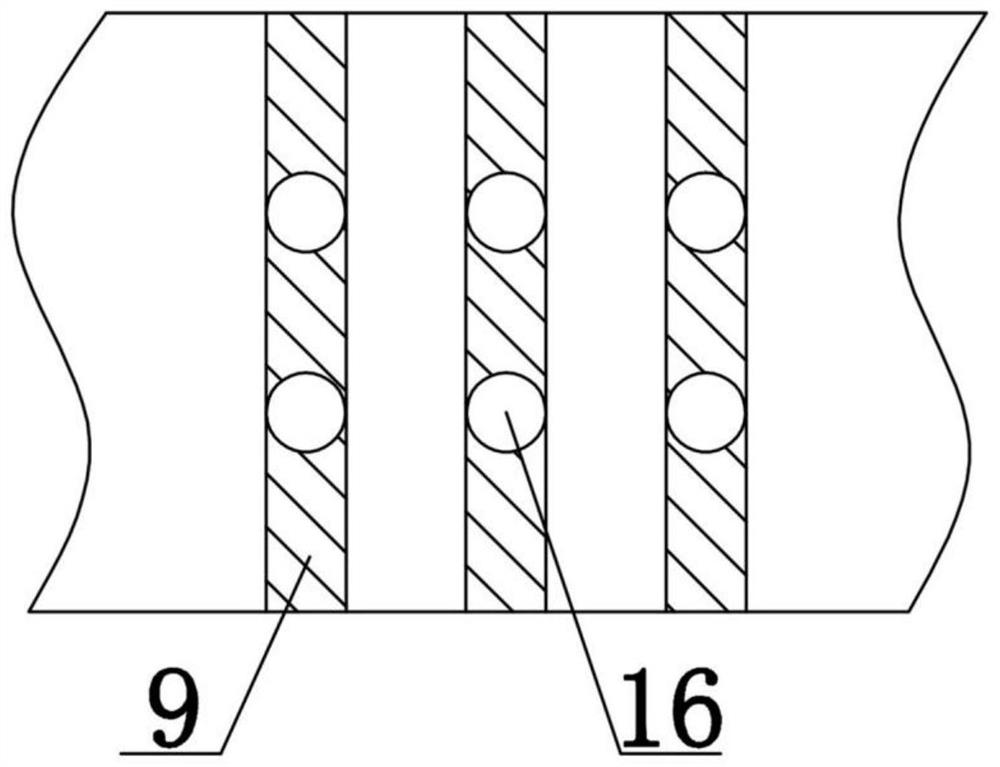

[0024] Such as figure 1 , figure 2 In the example shown, a thermal insulation structure of a gas turbine waste heat transmission pipeline includes a gas turbine 1 and a transmission pipe 2, the gas turbine 1 is connected to the transmission pipe 2, and a drain pipe 3 is installed on the transmission pipe 2, and heat conduction power generation Machine 8 and screen cloth one 9, the outer wall of drainage pipe 3 is connected with the inner side wall of conveying pipe 2, and screen cloth one 9 comprises several, and several screen cloth one 9 are evenly distributed in conveying pipe 2, and screen cloth one 9 and The heat conduction generators 8 are all connected to the inner side wall of the drain pipe 3, the material of the screen 9 is a heat conduction material, the heat conduction generator 8 is connected to the screen 9, and the gas turbine 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com