Agricultural three-jaw rake bending equipment

An agricultural and bending technology, which is applied in the field of agricultural three-claw iron rake bending equipment, can solve the problems of low work efficiency, cumbersome operation process, and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

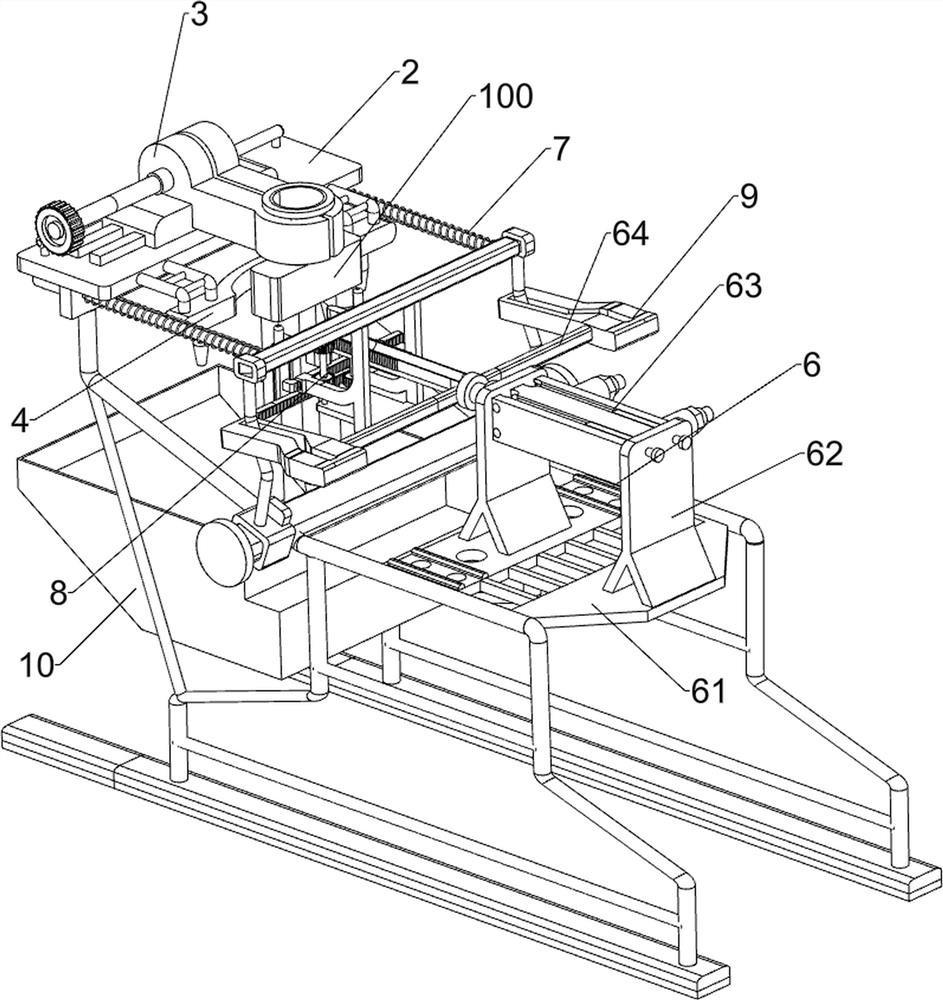

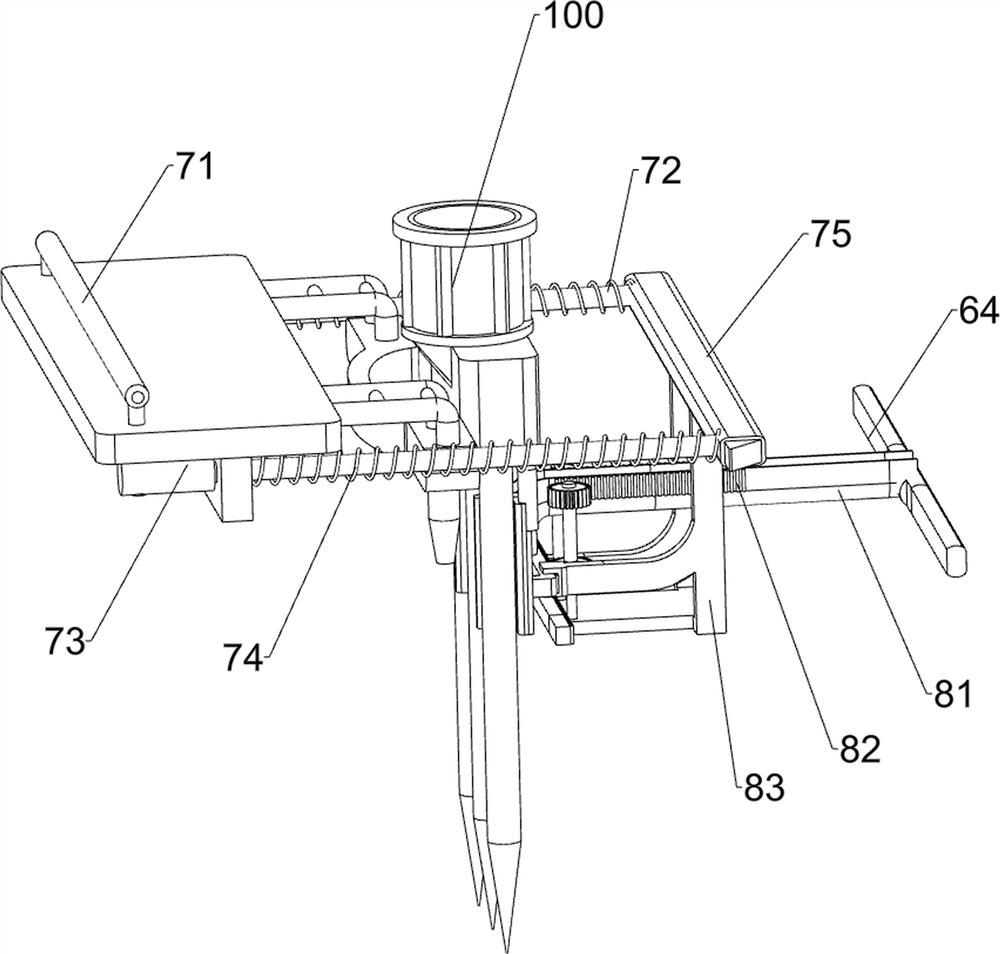

[0026] An agricultural three-claw iron rake bending equipment, such as Figure 1-5 As shown, it includes a frame 1, a fixed plate 2, a clamp table 3, a mounting frame 4 and a positioning rod 5. The left side of the top of the frame 1 is connected with a fixed plate 2, and the fixed plate 2 is equipped with a clamp table 3 and a fixed plate 2. The right side is connected with a mounting frame 4, and both sides of the bottom of the mounting frame 4 are connected with positioning rods 5, and also include an extrusion mechanism 6, a positioning guide assembly 7 and a bending mechanism 8, and the frame 1 is provided with an extrusion mechanism 6, The fixed plate 2 is provided with a positioning guide assembly 7, and a bending mechanism 8 is provided between the positioning guide assembly 7 and the extruding mechanism 6, and the extruding mechanism 6 and the bending mechanism 8 are connected by transmission.

[0027] The extruding mechanism 6 includes a mounting plate 61, a mounting...

Embodiment 2

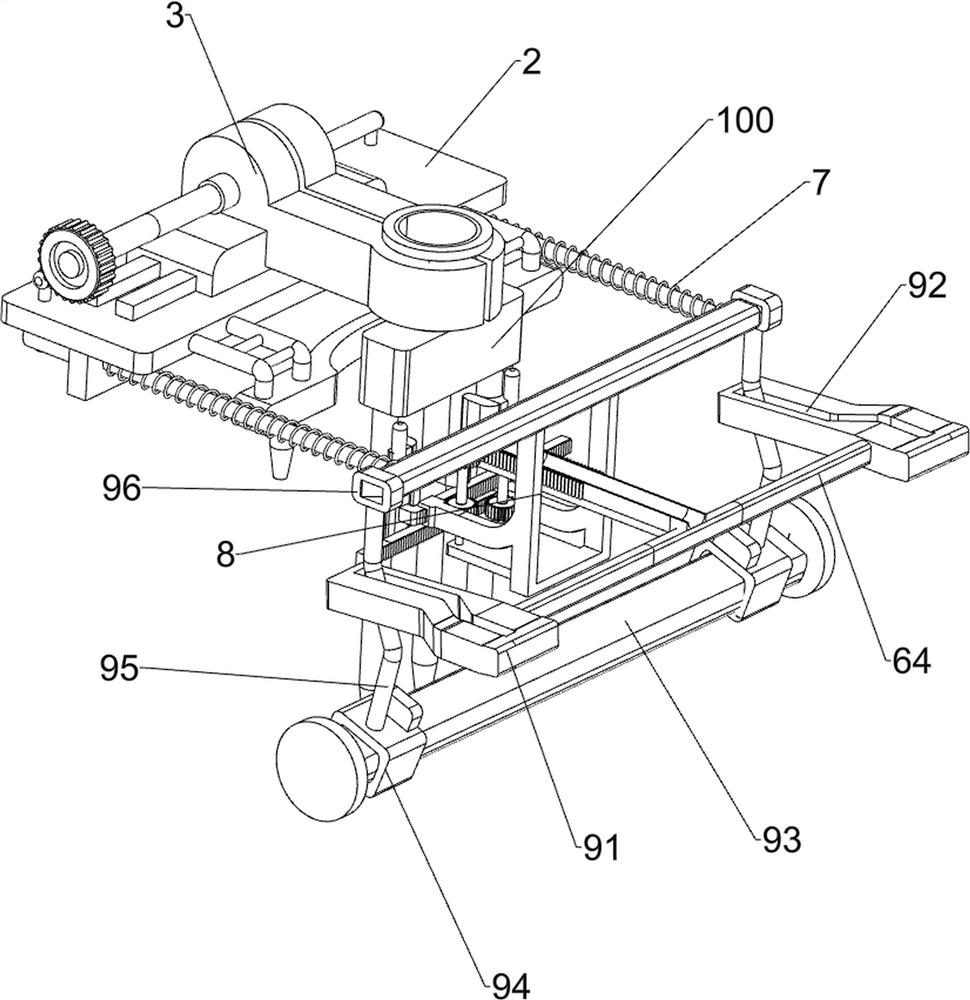

[0032] On the basis of Example 1, such as figure 2 with Figure 5 As shown, an automatic guide mechanism 9 is also included, and the automatic guide mechanism 9 includes a guide plate 91, a guide rail 93, a sliding sleeve 94, a connecting rod 95, a ferrule 96 and a wedge block 97, and both sides of the extruding rod 64 are connected with guides. Plate 91, has guide groove 92 on guide plate 91, and frame 1 middle part is connected with guide rail 93, and guide rail 93 front and rear both sides are all slidably connected with sliding sleeve 94, is connected with connecting rod 95 on the sliding sleeve 94, two connecting rods 95 are slidingly matched with the guide slots 92 on the two guide plates 91 respectively. The top of the connecting rod 95 is connected with a ferrule 96.

[0033]Initially, the n-type clamping rod 71 can be directly extracted, and the extruding rod 64 drives the guide plate 91 to move to the left when moving to the left. Since the wedge-shaped block 97 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com