Automatic bending device for two ends of copper wire

A bending device and copper wire technology, which is applied in the field of automatic bending devices at both ends of copper wires, can solve the problems of cumbersome operation process, low work efficiency, and manpower consumption, so as to achieve simple operation, improve work efficiency, and save manpower consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

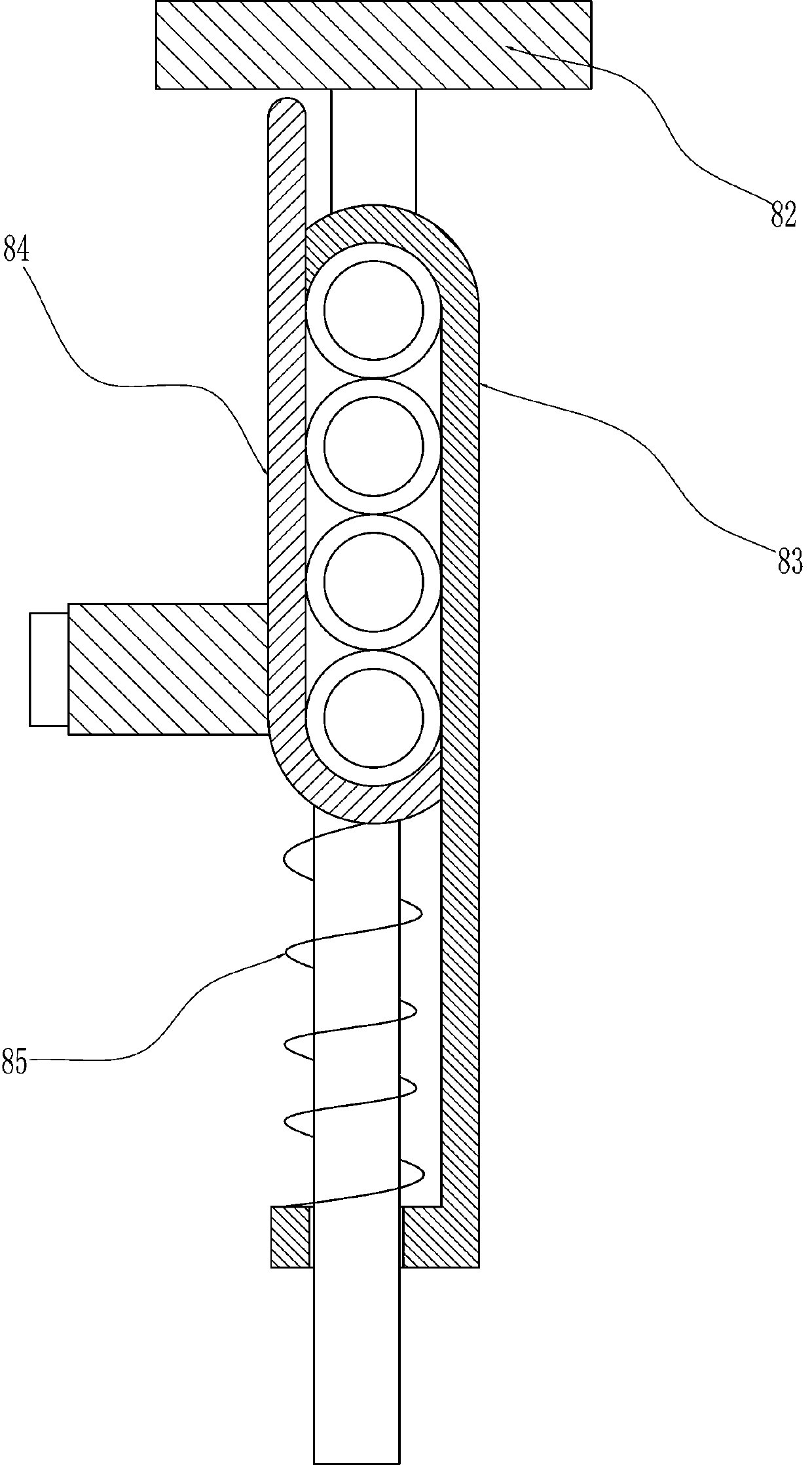

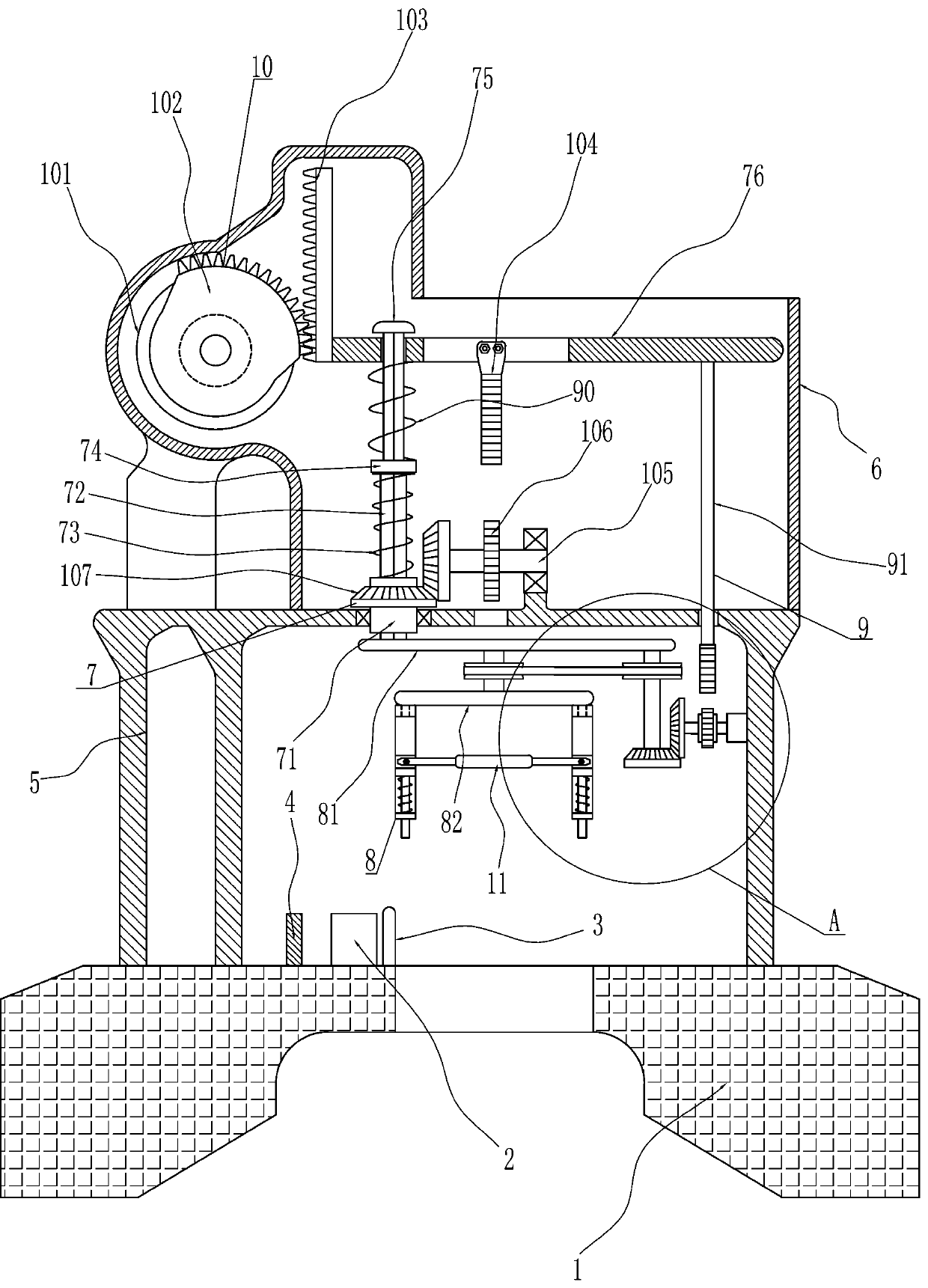

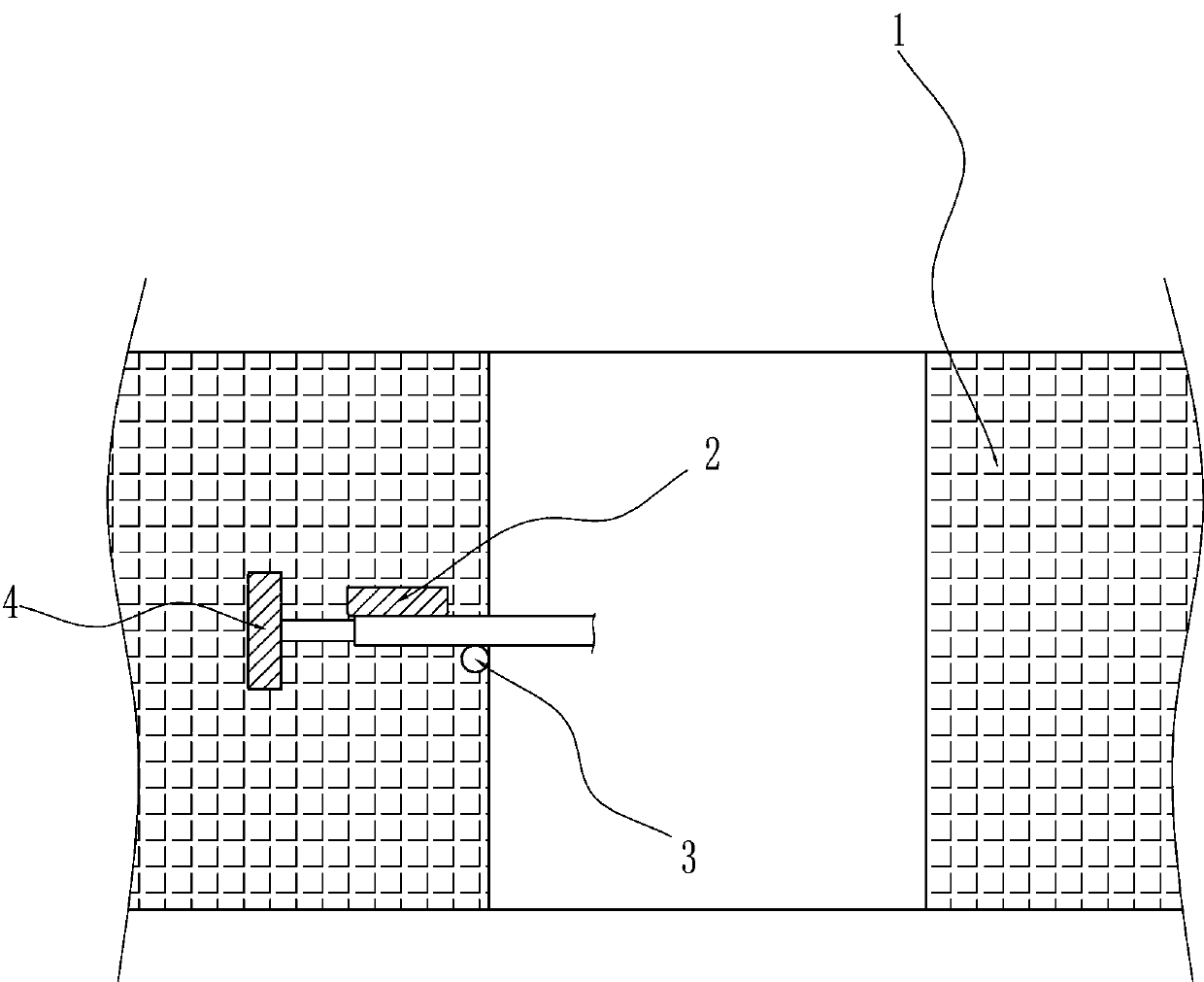

[0022] An automatic bending device at both ends of a copper wire, such as Figure 1-4 As shown, it includes a base 1, a first limiting plate 2, a second limiting plate 3, a torsion bar 4, a workbench 5 and an installation box 6, and the top of the base 1 is connected with the first limiting plate 2, the second limiting plate Plate 3 and torsion bar 4, the first limiting plate 2 is located at the rear side of the second limiting plate 3, the torsion bar 4 is located on the left side of the first limiting plate 2 and the second limiting plate 3, and the top of the base 1 is connected with Workbench 5, installation box 6 is installed on the top of workbench 5, and also includes moving assembly 7 and charging assembly 8, between workbench 5 and installation box 6, there is moving assembly 7, and moving assembly 7 is provided with charging assembly 8 .

[0023] The moving assembly 7 includes an inner diamond sleeve 71, a rhombus rod 72, a first return spring 73, an axle sleeve 74 ...

Embodiment 2

[0027] On the basis of Example 1, such as figure 1 As shown, a diamond-shaped guide rod 75 is also included, and the top of the bushing 74 is connected with a rhombus-shaped guide rod 75 , a sliding plate 76 is slidably matched with the diamond-shaped guide rod 75 , and there is a certain resistance between the sliding plate 76 and the diamond-shaped guide rod 75 .

[0028] When the slide plate 76 moves downward, the diamond-shaped guide rod 75 can play a guiding role.

[0029] Such as figure 1 and Figure 4 As shown, a rotating assembly 9 is also included, and the rotating assembly 9 includes a driving rack 91, a first rotating shaft 92, a one-way clutch 93, a driving gear 94, a second rotating shaft 95, a first bevel gear 96 and a compression spring 90, sliding The right side of the bottom of the plate 76 is connected with a driving rack 91, and the driving rack 91 is slidingly matched with the workbench 5. The inner right wall of the workbench 5 is rotatably connected wit...

Embodiment 3

[0032] Such as figure 1 As shown, a drive assembly 10 is also included, and the drive assembly 10 includes a motor 101, a sector gear 102, a first spur rack 103, a second spur rack 104, a mounting shaft 105, a cylindrical gear 106 and a second bevel gear 107, Mounting box 6 top left side is equipped with motor 101, is connected with sector gear 102 on the output shaft of motor 101, is connected with the first spur rack 103 that can mesh with sector gear 102 on the left side of slide plate 76, is connected with on slide plate 76 The second spur rack 104, the top of the workbench 5 is rotatably connected with the mounting shaft 105, the mounting shaft 105 is connected with a cylindrical gear 106, the cylindrical gear 106 will mesh with the second spur rack 104, and the end of the mounting shaft 105 is connected to the inner diamond sleeve Both the pipes 71 are connected with second bevel gears 107, and the two second bevel gears 107 mesh with each other.

[0033] The starter mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com