Shaping equipment

An equipment and plate technology, applied in the field of plastic forming equipment that can elastically reshape plates, can solve the problems of lowering the overall yield, lack of plate elasticity, damage to the plate by the contact area, etc., to increase the convenience of operation, improve the quality rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

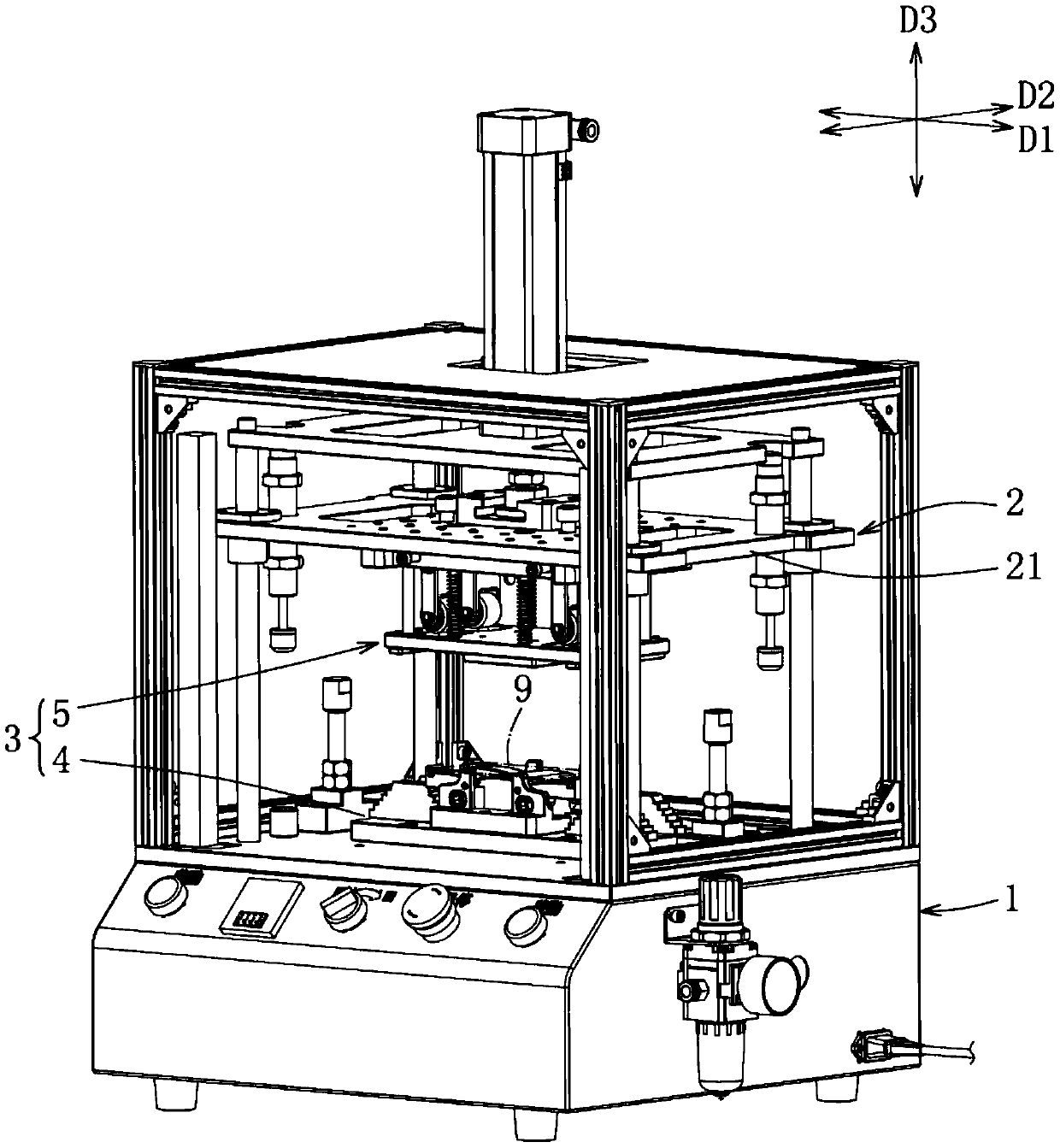

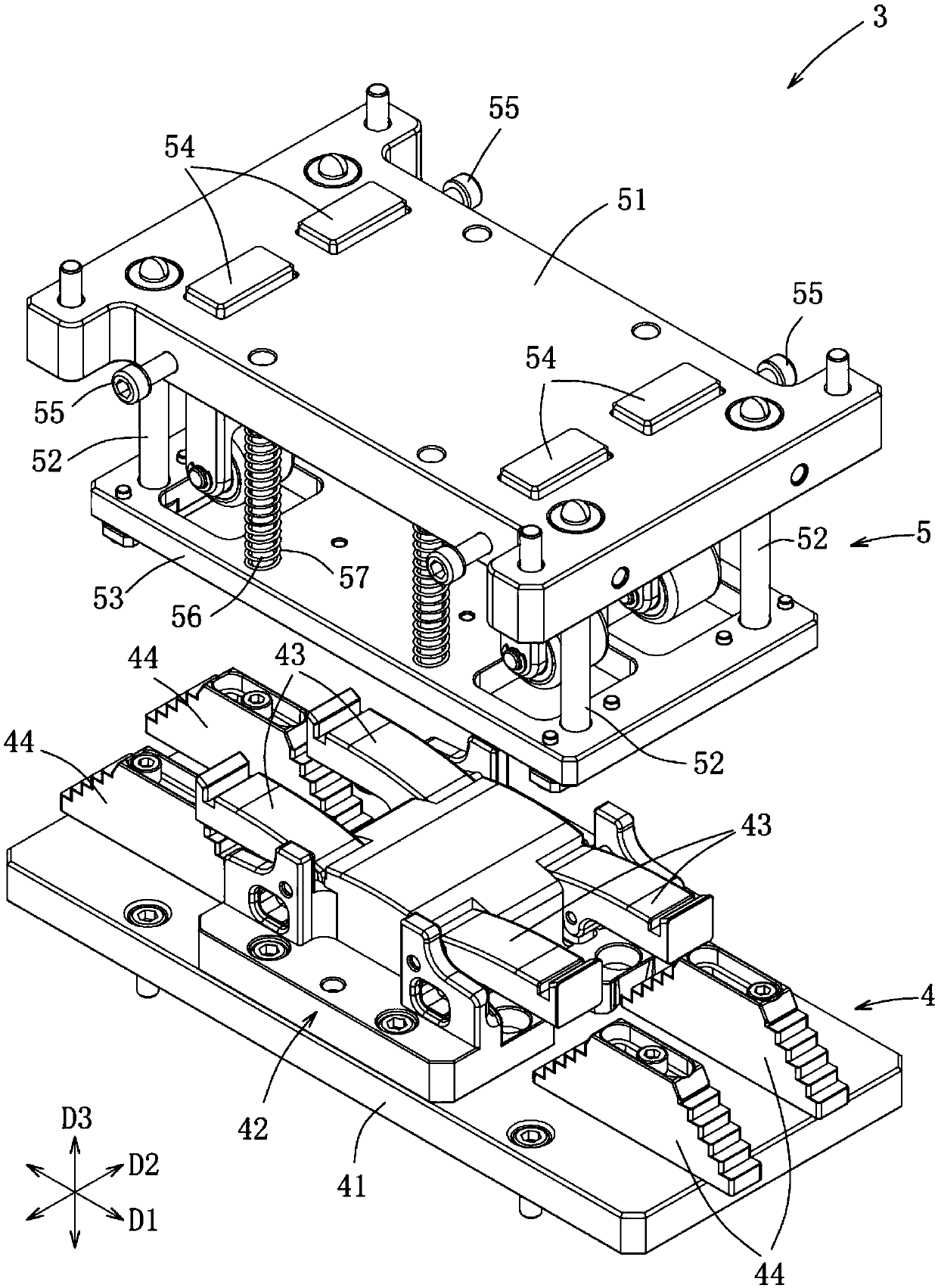

[0038] refer to figure 1 , an embodiment of the molding equipment of the present invention for molding a plate 9 , the molding equipment includes a carrier 1 , a driving device 2 and a pressing device 3 . In this embodiment, the plate 9 is, for example, a mobile phone case, but not limited to the mobile phone case, as long as the plate 9 is made of ductile material, it can be processed by shaping equipment.

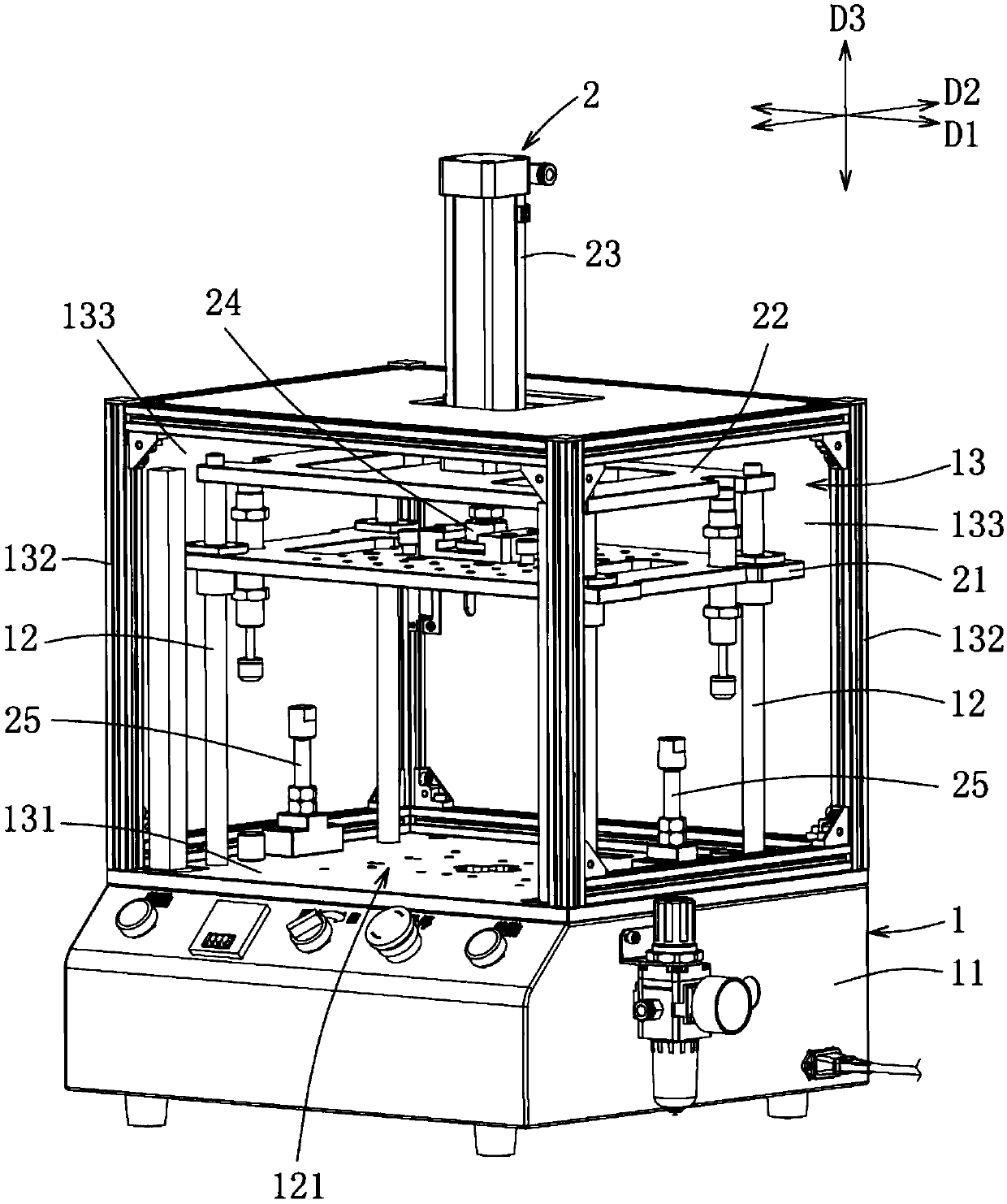

[0039] refer to figure 1 and figure 2 The stage 1 includes a control base 11 , four inner brackets 12 surrounding the top surface of the control base 11 for the drive device 2 to install, and a shielding unit 13 surrounding the inner bracket 12 and forming a forward opening 131 . The inner frame 12 jointly defines a working area 121 for the driving device 2 and the pressing device 3 to perform mechanical actions. In addition, the shielding unit 13 has four outer frames 132 surrounding the inner frame 12 and a plurality of shields 133 connected to the outer frames 132 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com