Soil screening device for soil remediation

A soil screening and soil remediation technology, which is applied in the field of soil remediation, can solve problems such as low yield, soil water content decline, and soil environment deterioration, and achieve the effects of rapid screening, control of air dust content, and avoiding screening blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

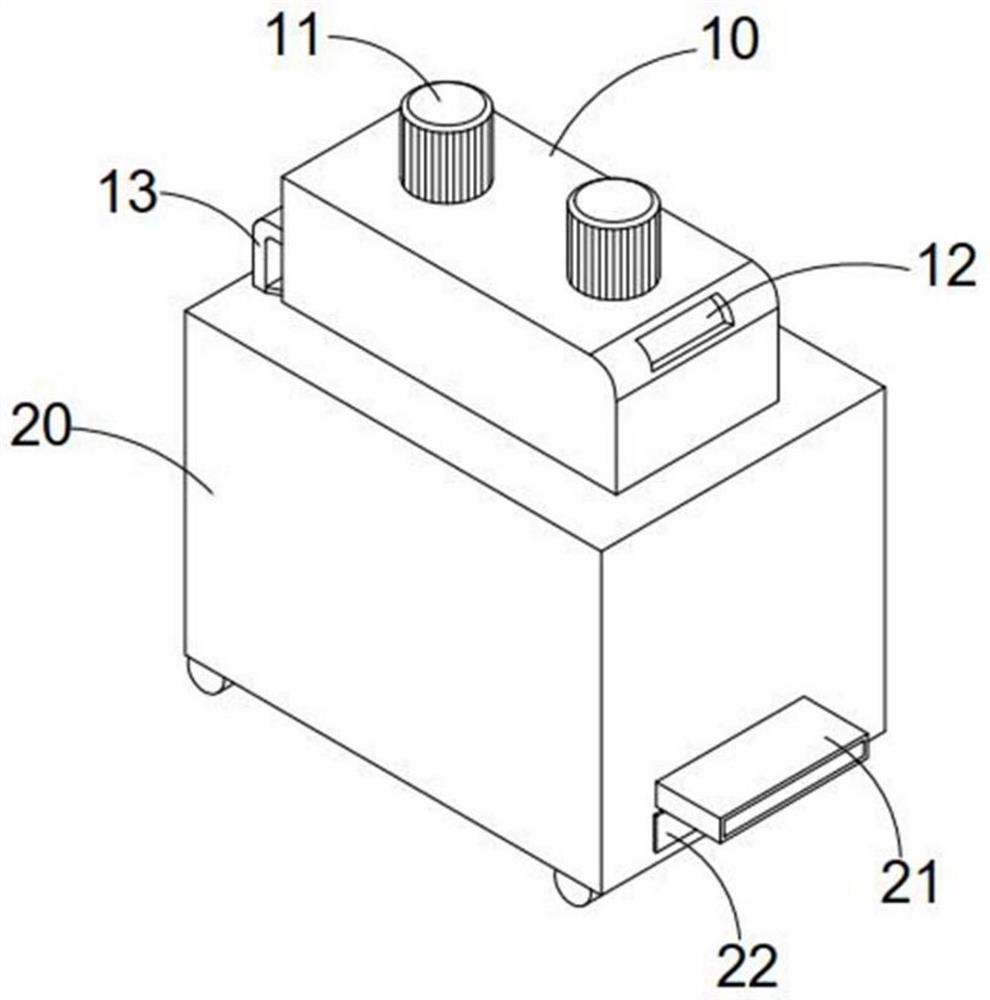

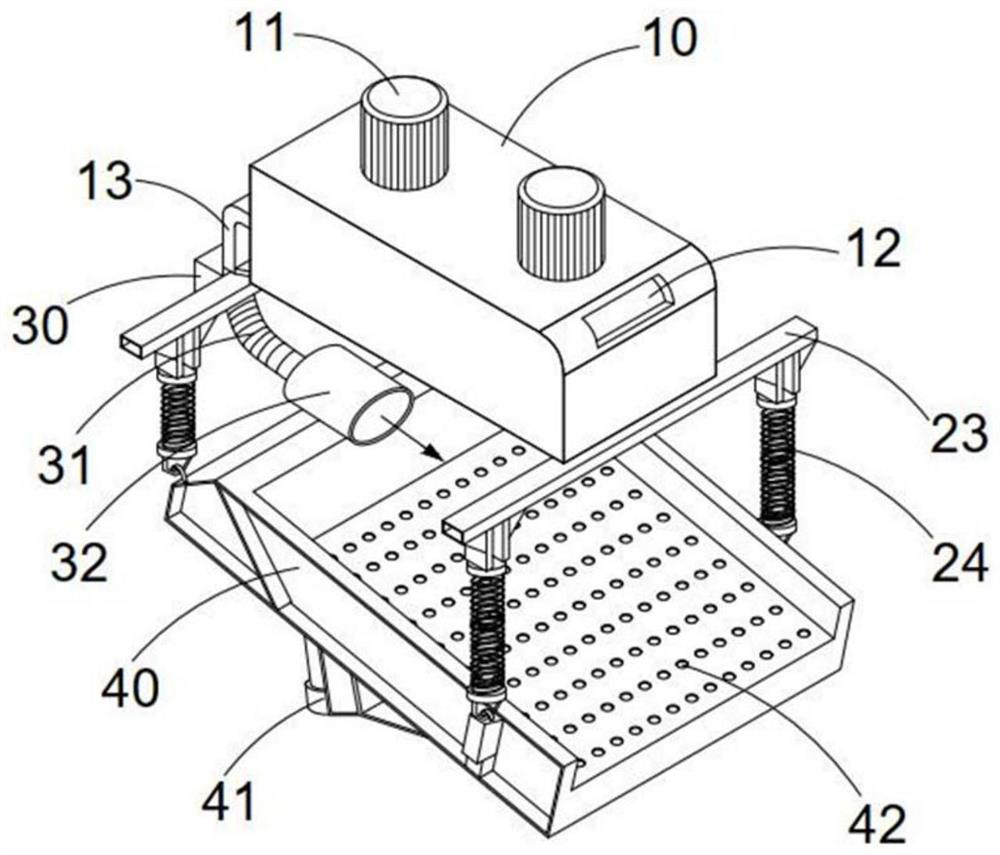

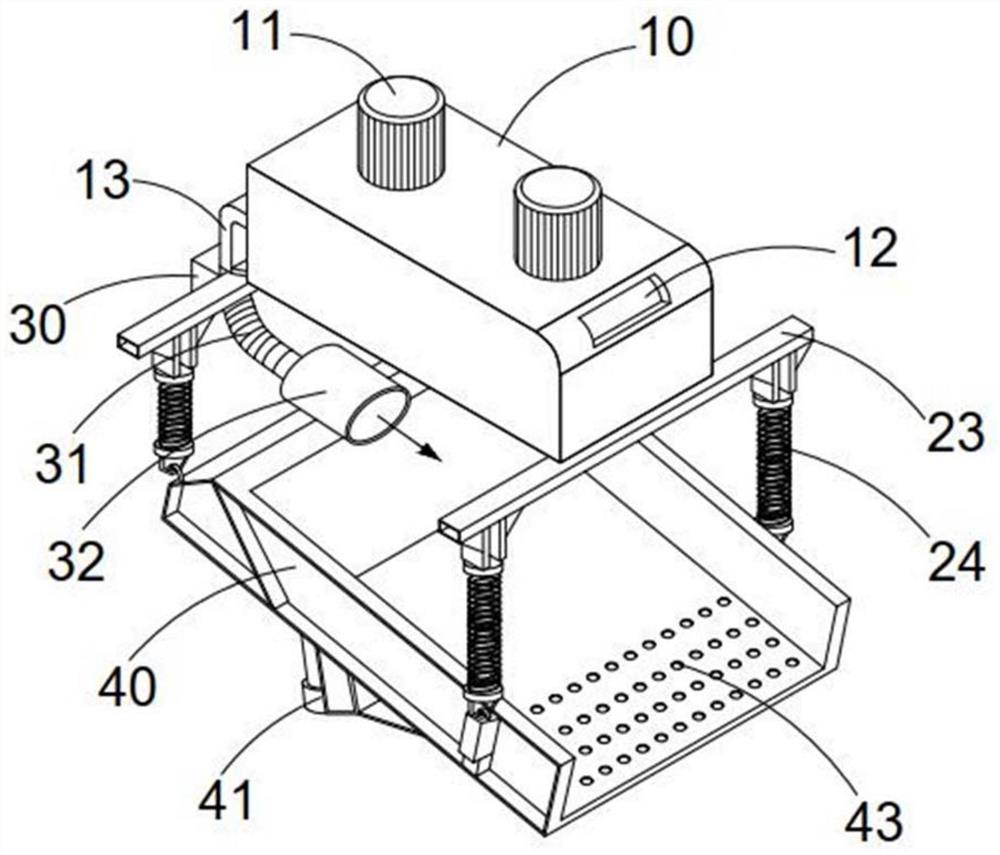

[0044] See attached Figure 1-3 , 8-14, the soil screening device for soil remediation, including:

[0045] The crushing assembly 10, the crushing assembly 10 is used for material crushing,

[0046] Screening box 20, the screening box 20 is arranged under the crushing assembly 10, the screening box 20 is used for material screening, the side wall of the crushing assembly 10 is connected to the upper end of the screening box 20 through the first discharge pipe 13 , sending the crushed material into the screening box 20,

[0047] The screening box 20 is provided with a screening base 40, and above the screening base 40, two connecting support rods 23 which are parallel to each other and have a distance from each other are arranged. Parts are fixedly connected to the inner wall of the screening box 20, and the bottoms of the two ends of the connecting support rod 23 are respectively connected to the screening base 40 through the first spring 24. The bottom of the screening base...

Embodiment 2

[0062] The further optimization scheme of present embodiment on the basis of embodiment 1 is: see appendix Figure 1-7 As shown, the crushing assembly 10 includes a crushing box, and the crushing box is provided with a horizontally arranged partition filter plate 17, and the surface of the partition filter plate 17 is provided with through holes, and the partition filter plate 17 is used to separate The crushing box is divided into upper and lower chambers, the upper chamber is the crushing chamber, the lower chamber is the auxiliary discharge chamber 60, and the crushing chamber is provided with a vertically arranged first partition plate 19 to divide the crushing chamber into The first auxiliary crushing chamber and the second auxiliary crushing chamber, the upper end of the first partition plate 19 is connected to the top of the crushing box, the bottom of the first partition plate 19 is connected to the partition filter plate 17, and the first partition plate 19 is connecte...

Embodiment 3

[0066] The further optimization scheme of present embodiment on the basis of embodiment 2 is: see appendix Figure 4-7 As shown, the side of the auxiliary discharge chamber 60 communicates with the first discharge pipe 13 through the secondary discharge pipe 14, and the secondary discharge pipe 14 is located below the second auxiliary crushing chamber. A horizontally arranged discharge shaker plate 15 is arranged in the chamber 60 , and the bottom surface of the discharge shaker plate 15 is connected to the inner bottom surface of the auxiliary discharge chamber 60 through uniformly provided second springs 18 .

[0067] The secondary discharge pipe 14 is designed to discharge the soil particles in the auxiliary discharge chamber 60 into the first discharge pipe 13, wherein, after the soil in the first auxiliary crushing chamber is crushed, it is located in the second One-time crushing, the crushing produces less soil that meets the sieving particles, and the number of falling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com