Timepiece part, timepiece comprising same, method for manufacturing same, and surface treatment method

A technology of surface treatment and manufacturing method, applied in the field of watches and clocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

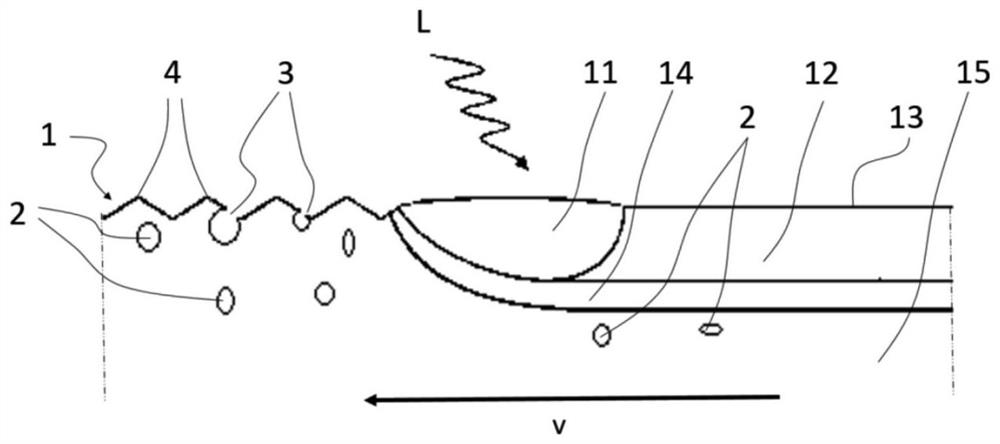

[0023] The invention is based on a first option, consisting in the use of powder metallurgy or additive manufacturing techniques as a first step in the manufacturing method of watch components. This option has the first advantage of allowing complex and diverse shapes to be formed, including, for example, shapes not achievable by traditional metallurgical methods. On the other hand, this first option also has a second advantage, allowing the use of a wide variety of materials, even alloys or combinations of elements not obtainable by another conventional method, such as certain metal alloys that are not compatible with conventional metallurgy . Therefore, this first option according to the invention makes it possible to partly respond to the object of the invention.

[0024] However, these selected technologies have the particular characteristic of forming porous and often heterogeneous parts with visible surface defects, such as visible or perceptible irregularities such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com