Mandrel type casing head and using method thereof

A casing head and mandrel technology, applied in the casing head field, can solve the problems of cumbersome handling, the ejection of the top wire to hurt people, and the failure to deliver to the position, so as to achieve high construction safety, avoid equipment wear, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0058] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of structure, change of proportional relationship or adjustment of size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0059] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

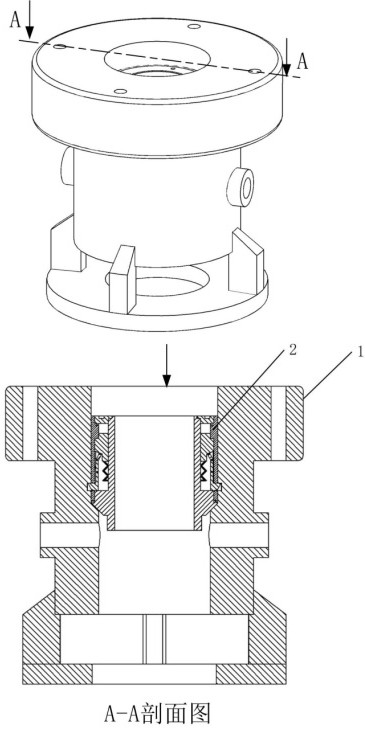

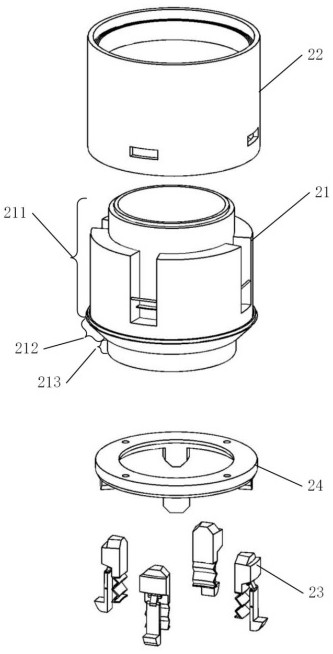

[0061] combined with Figure 1-10 , this embodiment provides a mandrel type casing head, including a hollow casing head body 1 and a mandrel hanger 2 set in the casing head body 1,

[0062] The inner wall circumference of the casing head body 1 is provided with a card slot 1211,

[0063] The mandrel hanger 2 includes a hollow hanger body 21 and a casing 22 sleeved outside the hanger body 21 , and the hanger body 21 is provided with a snap-in piece corresponding to the slot 1211 23 and a rotating member 24 that drives the engaging member 23 to engage or leave the engaging slot 1211 , and the housing 22 is provided with a first through hole 2211 corresponding to the engaging slot 1211 .

[0064] During installation, the mandrel hanger 2 is lowered into the casing head body 1 for setting. When setting, align the first through hole 2211 on the casing 22 with the slot 1211 on the inner side wall of the casing head body 1. The rotating member 24 rotates, and the clamping member 23...

Embodiment 2

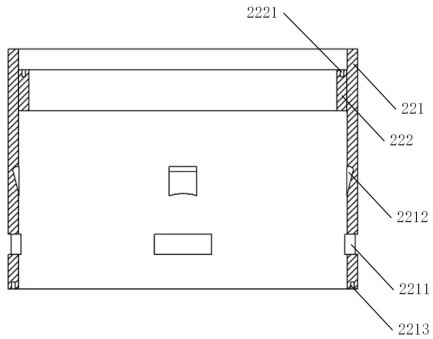

[0085] This embodiment is a modified example of Embodiment 1, such as Figure 11 to Figure 13 As shown, this embodiment provides another structure of the clip 23 to realize the locking and unlocking of the mandrel hanger 2 and the casing head body 1 , and the rest of the structure is the same as that of the first embodiment. The specific technical scheme is as follows:

[0086] Such as Figure 11 and Figure 12 As shown, the lower end surface of the slider 231 is axially provided with a first chute 2311, and the first chute 2311 is provided with the elastic member 233, and the elastic member 233 includes a first guide block extending axially. 2331 and a first spring 2332, one end of the first spring 2332 is connected to the top of the first chute 2311, and the other end is connected to the first guide block 2331, and the first chute 2311 can move along the first guide block 2331 slides axially; the lower end surface of the slider 231 away from the first chute 2311 is provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap