Small-size and wide-range pressure sensor

A pressure sensor, large-range technology, applied in the field of large-range pressure sensor and small size, can solve the problem of easy tearing and damage of the right-angle part, and achieve the effect of improving the range and service life, improving the sensitivity, and improving the range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

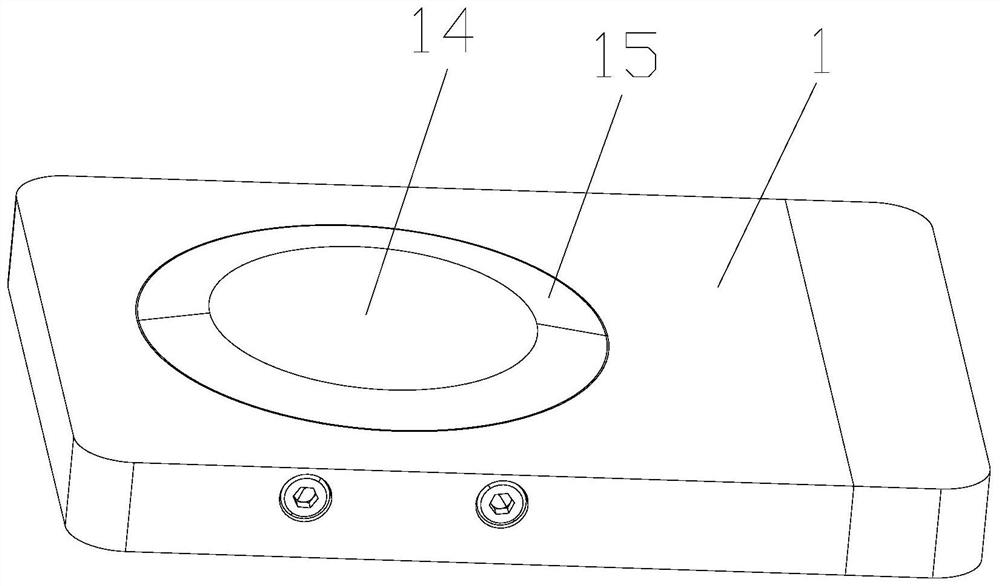

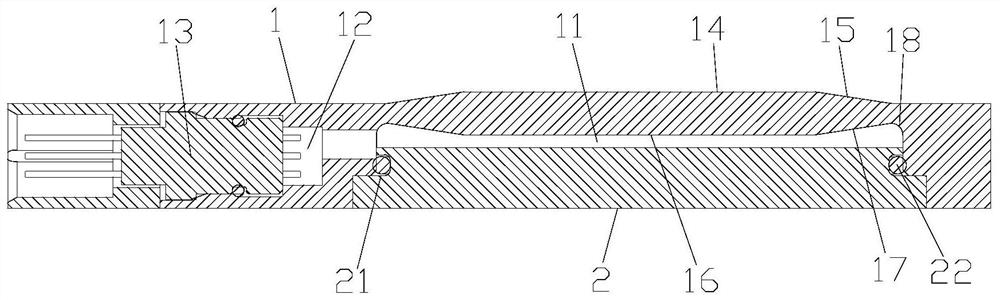

[0021] Such as figure 1 and figure 2 As shown, the present invention provides a small-sized, large-range pressure sensor, including: a housing 1, the housing 1 has a cavity 11, the cavity 11 is filled with liquid, the liquid can be silicone oil , and one side of the housing 1 is provided with an opening communicating with the cavity 11, and the size of the opening matches the size of the cavity, the opening is provided with a bottom cover 2 for sealing the cavity, the One side of the housing 1 is provided with a first through hole 12 communicating with the cavity 11, and a connector 13 is arranged in the first through hole 12, and the connector not only plays the purpose of sealing the first through hole, but also , the cavity end of the connector 13 is provided with a diffused silicon sensor, and the cavity wall on the side of the housing 1 opposite to the bottom cover 2 has an outward first protrusion 14 and an inward second protrusion. The protrusion 16 has a first slope...

Embodiment 2

[0029] Such as figure 1 and figure 2 As shown, the present invention provides a small-sized, large-range pressure sensor, including: a housing 1, the housing 1 has a cavity 11, the cavity 11 is filled with liquid, the liquid can be silicone oil , and one side of the housing 1 is provided with an opening communicating with the cavity 11, and the size of the opening matches the size of the cavity, the opening is provided with a bottom cover 2 for sealing the cavity, the The edge of the bottom cover 2 is provided with a step structure 21. Correspondingly, the edge of the opening is also provided with a step structure on the housing matching the step structure 21, and the bottom cover 2 is interference fit with the housing 1, One side of the housing 1 is provided with a first through hole 12 communicating with the cavity 11, and a connector 13 is arranged in the first through hole 12, and the connector not only serves the purpose of sealing the first through hole At the same ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com