Method for measuring the surface shape of doped silicon wafer based on near-infrared low-coherent light

A technology of surface topography measurement and low-coherence light, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of surface measurement after doping silicon wafers, and improve the contrast of interference fringes, improve efficiency and accuracy , the effect of increasing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

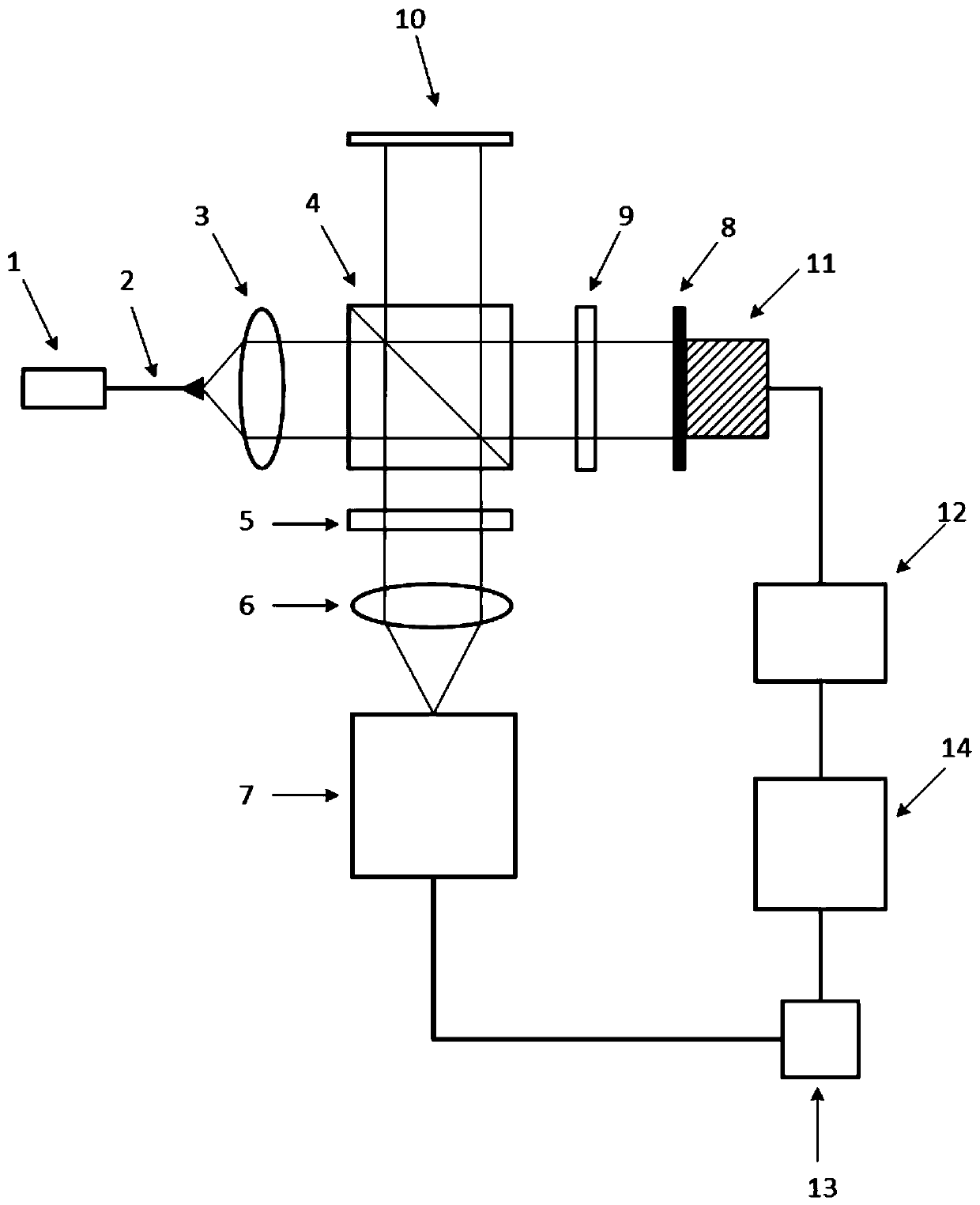

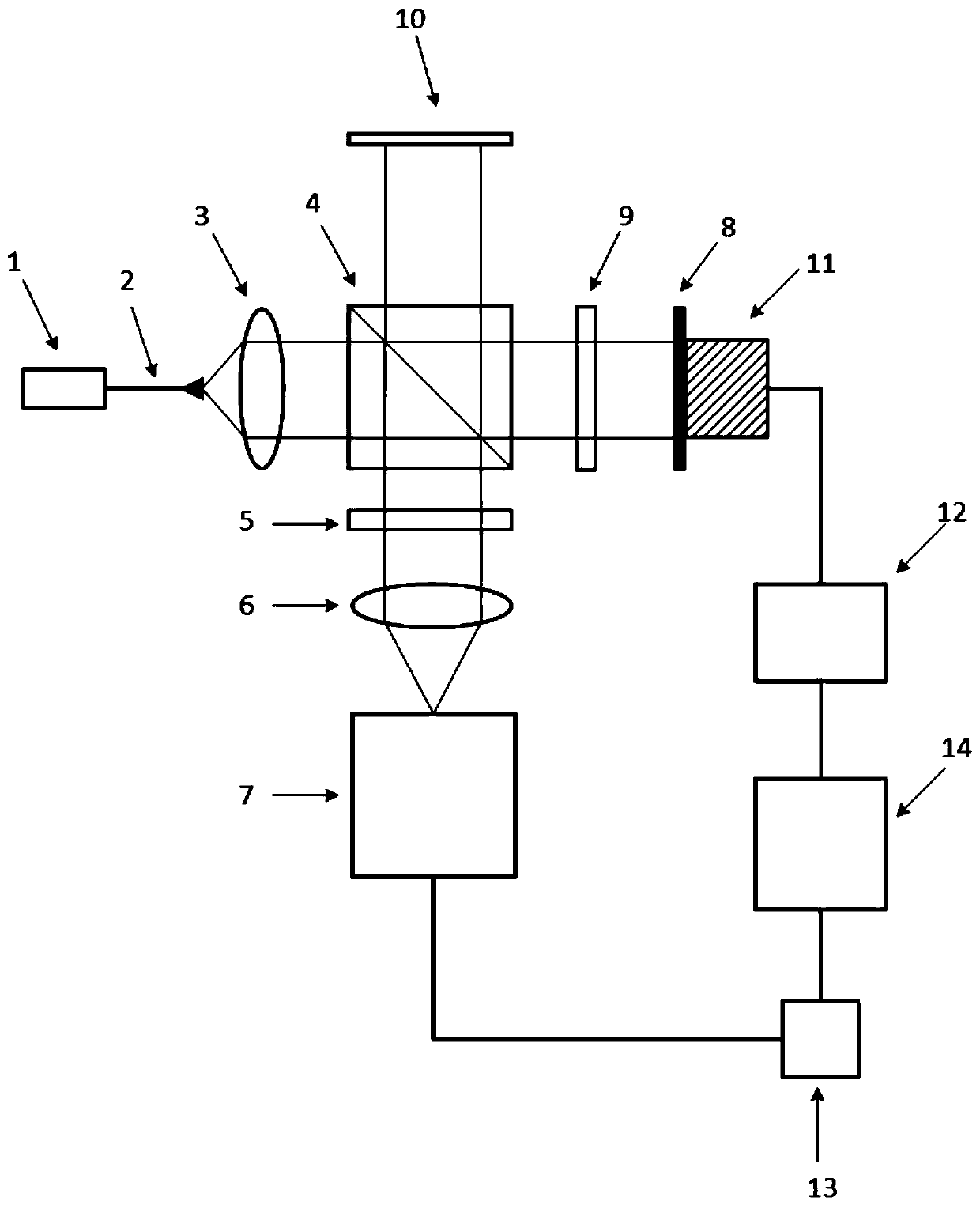

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0021] A method for measuring the surface topography of a silicon wafer doped with near-infrared low-coherence light, comprising the following steps:

[0022] 1) The measurement device of a near-infrared broadband light source is selected; a near-infrared light source with a center wavelength of 1550nm and a bandwidth of 50nm is selected.

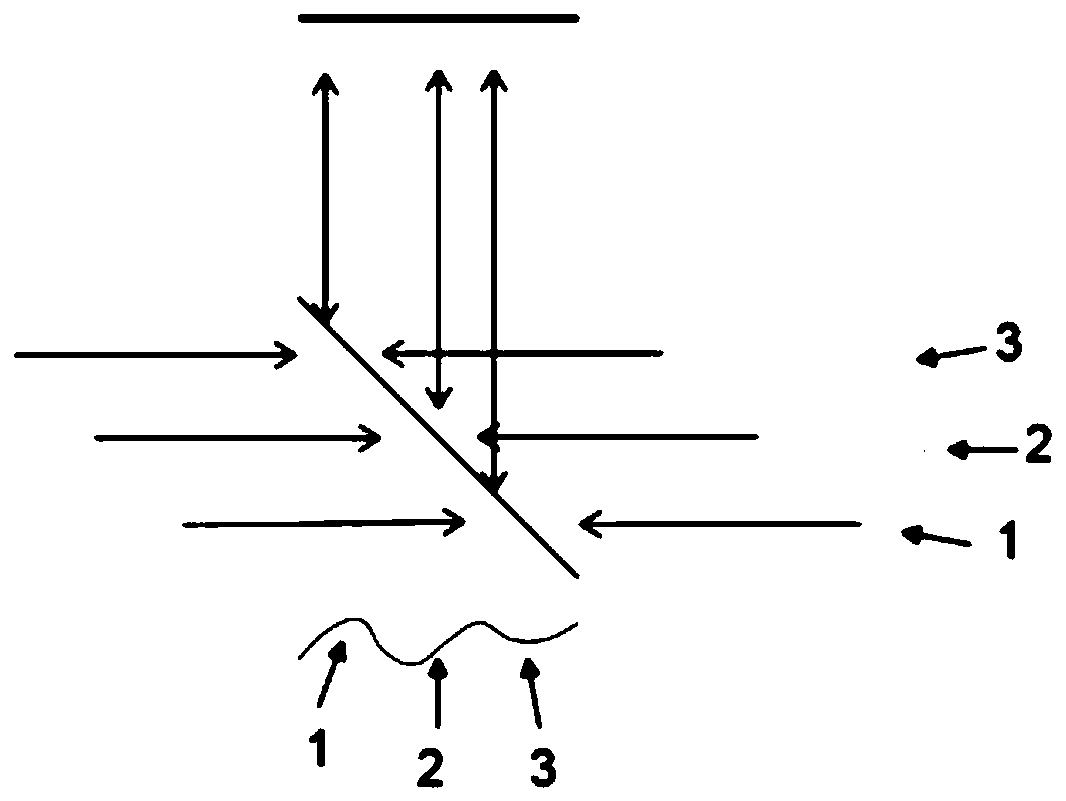

[0023] 2) Build a Michelson interferometer with a movable reference arm and a measuring arm. The circuit board of the Michelson interferometer controls the stepping motor, so that the optical path difference between the reference optical path and the measured optical path is gradually changed, and the silicon wafer Scanning interference of the surface to be measured;

[0024] 3) Finally, the near-infrared camera is used to continuously photograph the interferogram, and the interfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com