Adjusting device and method for controlling an exit thickness of a nozzle exit gap of a flat film machine

A technology of outlet thickness and nozzle outlet, applied in the field of adjustment devices, can solve problems such as difficulty in reproduction and inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

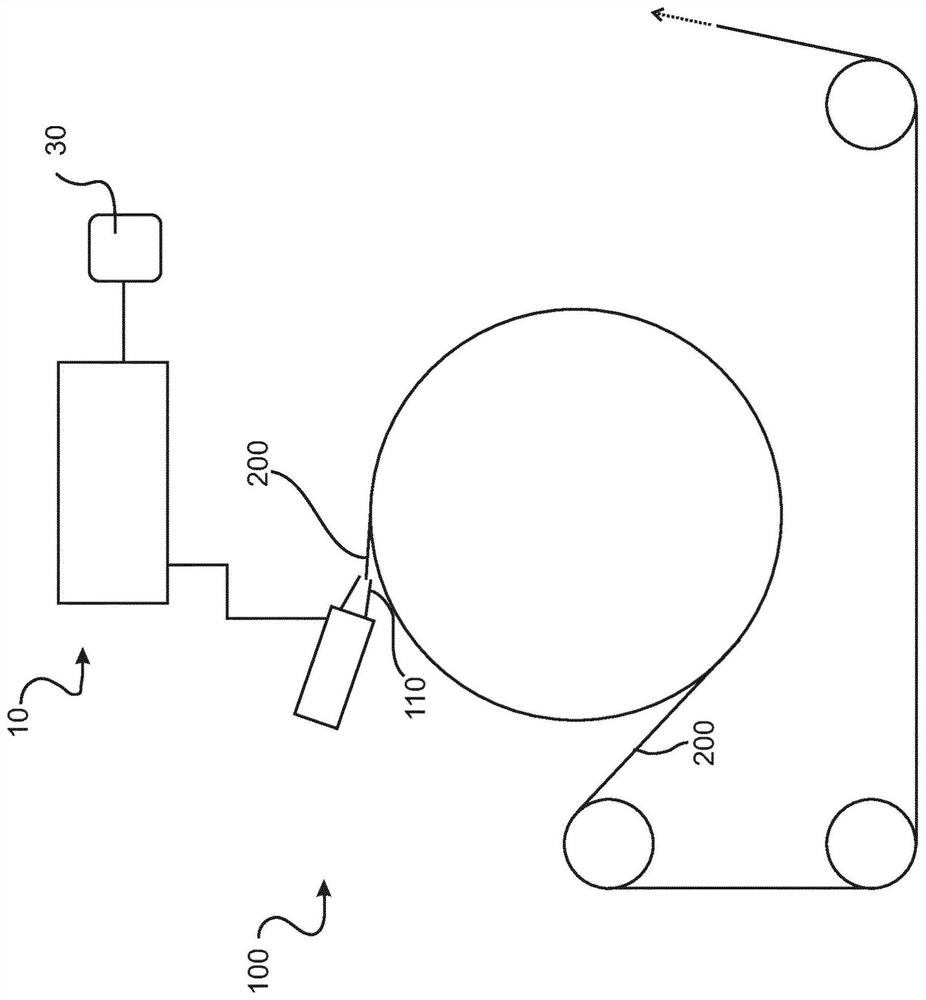

[0034]figure 1 A flat film machine 100 is shown schematically. The melt is output through the nozzle outlet slit 110, and then the film web 200 is cooled on a large cast roller or the cooling roller. Further delivery of the chilled thin film web 200 is shown by an arrow and, for example, a film volume can be wound. By means of the adjustment device 10, the outlet thickness AD of the nozzle device 110 can be changed, so that the thickness distribution of the melt thickness distribution or the thin film web web 200 can be affected. Here, it is also clear that the adjustment device 10 can use the corresponding storage device 30, and the specific relative position of the individual regulating bolt 20 can be stored in the storage device 30.

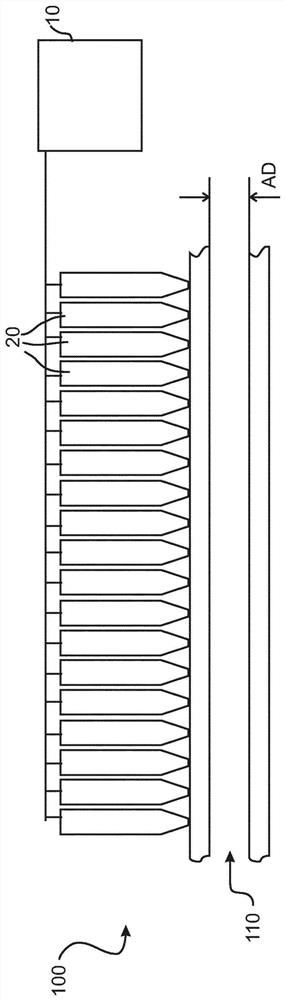

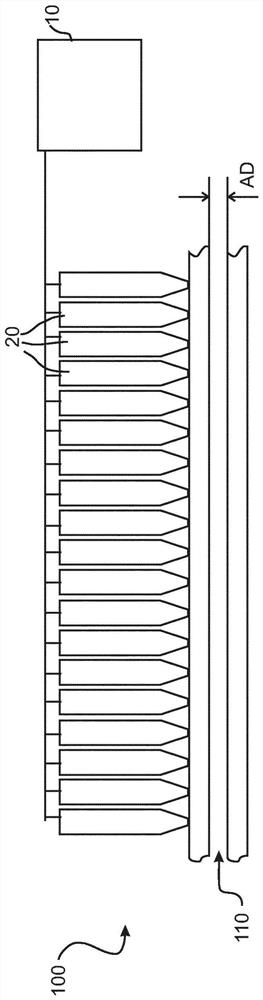

[0035]infigure 2 withimage 3 A top view of the nozzle outlet slit 110 of the flat machine 100 can be seen in the middle. By means of the adjustment device 10, all individual regulatory bolts 20 can now be specifically controlled in their longitudinal e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com