High-speed stable anti-blocking garbage line wind selection line

A stable and anti-blocking technology, used in solid separation, separation of solids from solids by air flow, cyclone devices, etc., which can solve problems such as low production efficiency, land occupation, and low sorting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

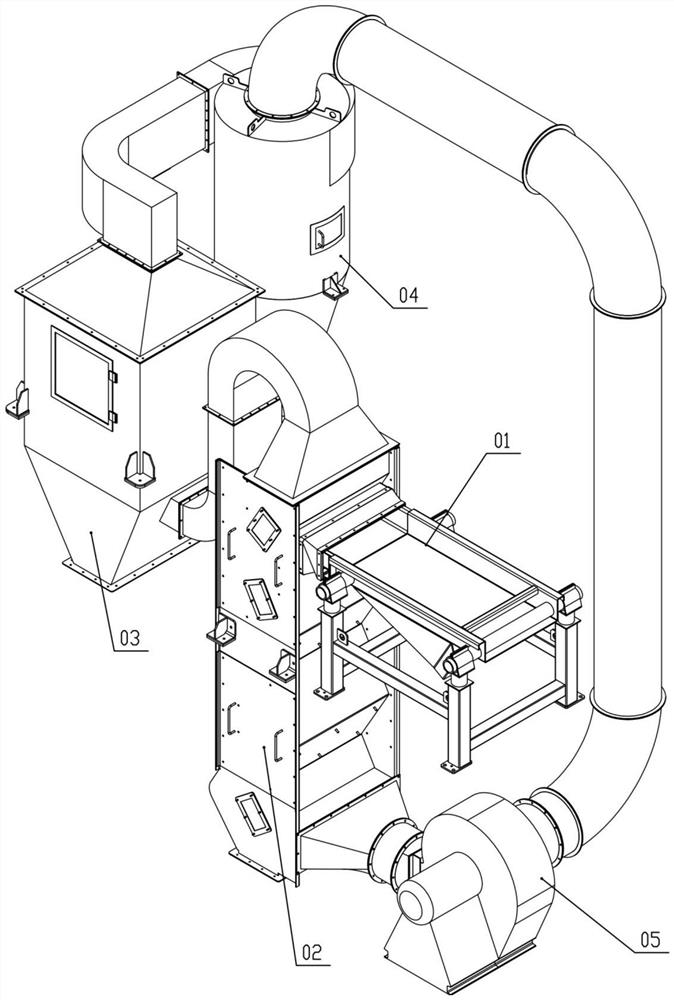

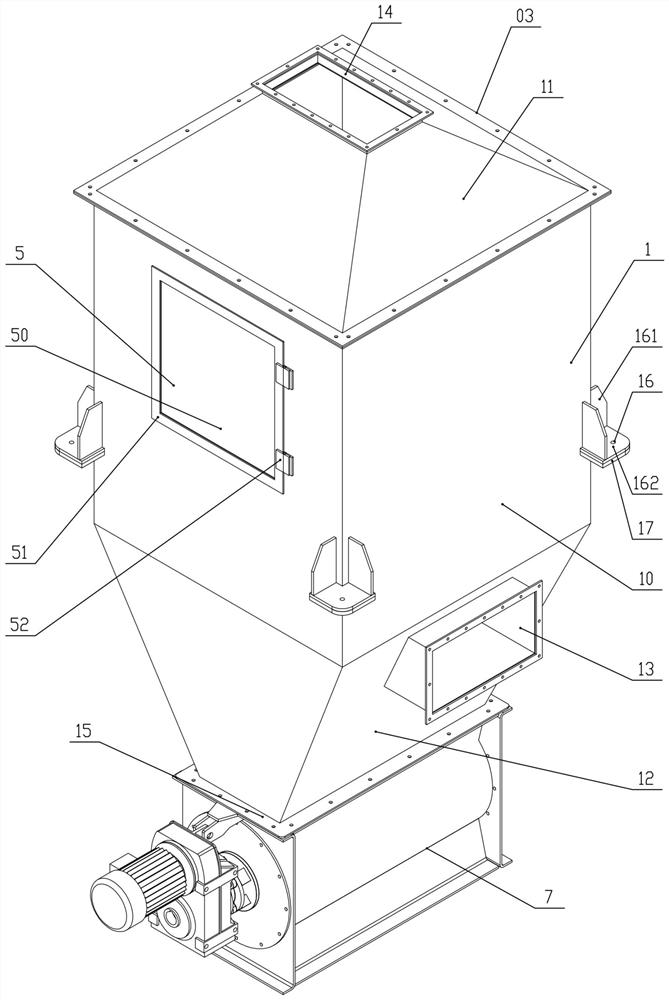

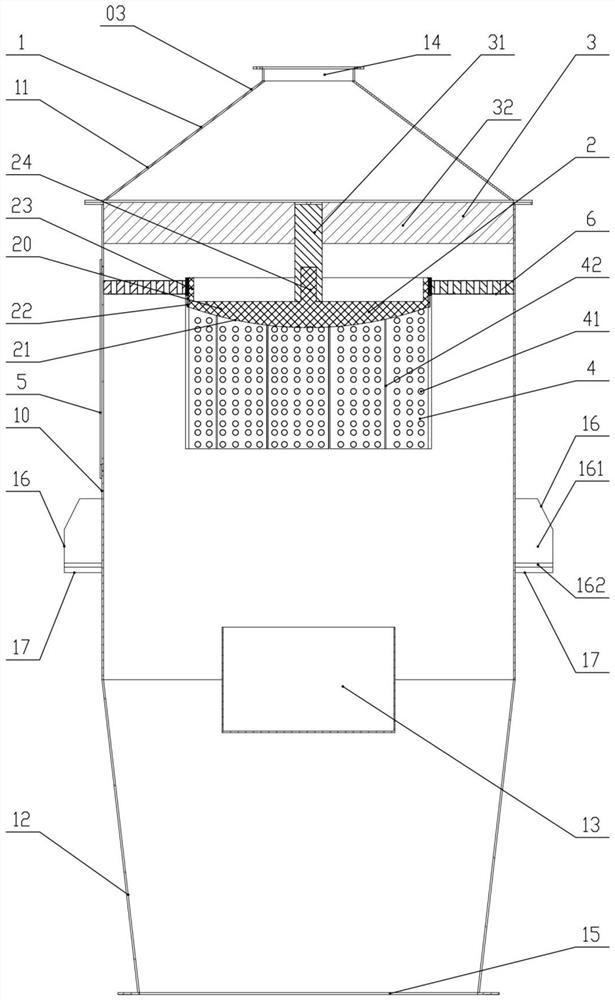

[0035] Figure 1 to Figure 10 Schematically shows a high-speed, stable and anti-clogging waste winnowing line according to an embodiment of the present invention. As shown in the figure, the device includes a vibrating feeder 01, a bulk separator 02, a sedimentation splitter 03, and a cyclone separator 04; the vibrating feeder 01 feeds materials evenly; the feed port of the bulk separator 02 Connected to the discharge nozzle of the vibrating feeder 01, the liner 024 is detachably installed on the blanking plate of the large material sorter 02, and the main fan is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com