Horizontal clamping type wall capable of containing pipeline and construction method

A horizontal and wall technology, which is applied to the horizontal wall and construction field, can solve the problems of hindering the installation of the wall and reducing the installation efficiency of the prefabricated wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

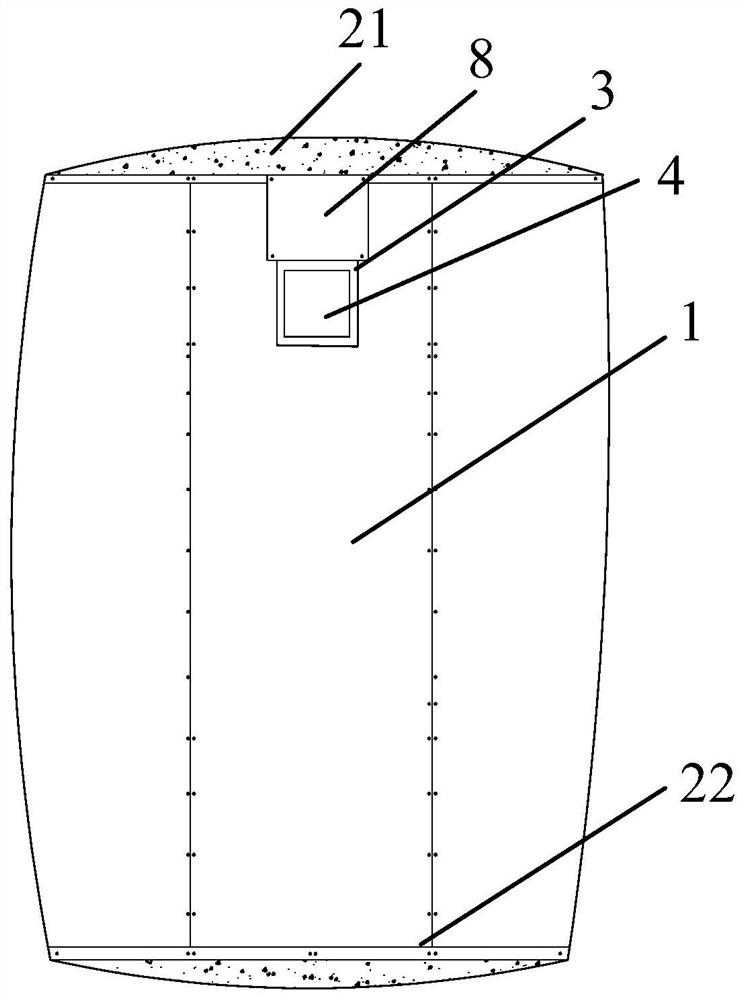

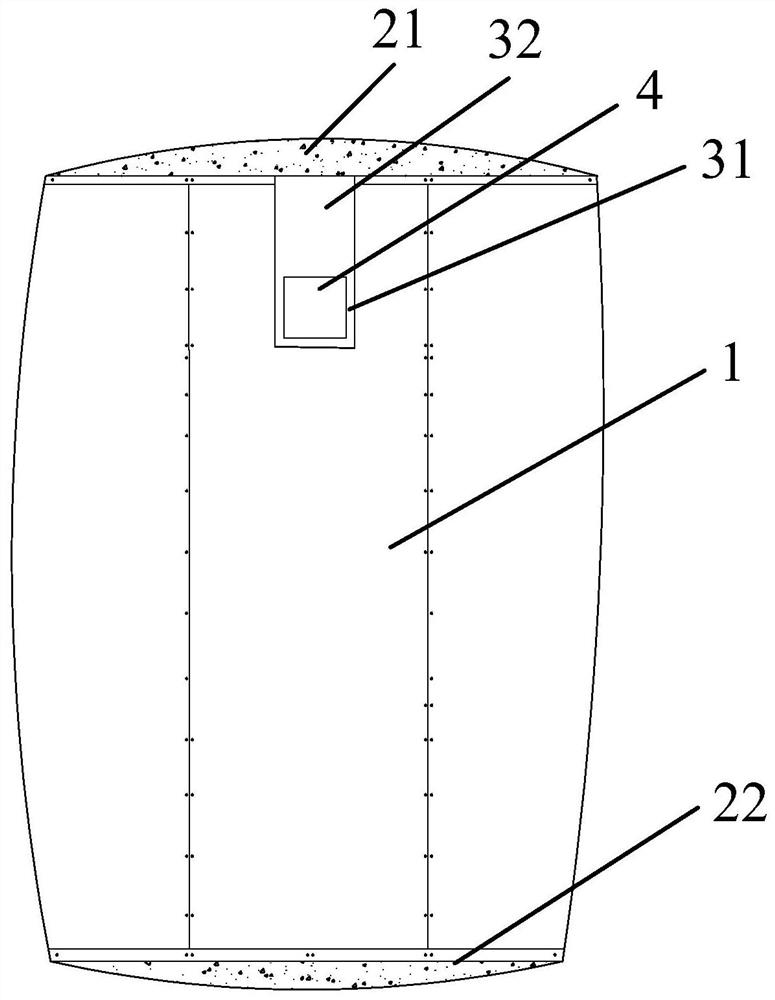

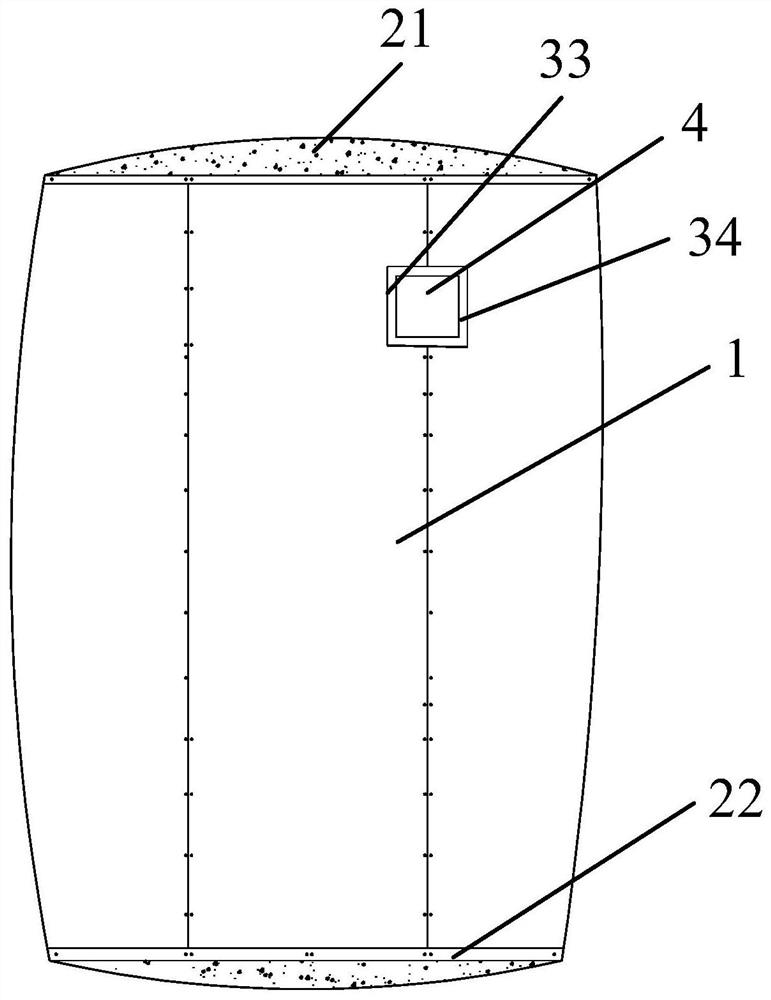

[0042] The embodiment of the present application provides a card-horizontal wall that can accommodate pipes, such as Figure 1 to Figure 12 As shown, the card-horizontal wall that can accommodate pipes includes a wall module erected between the upper and lower floors. The wall module includes a wall panel unit 1 and a first wall panel 7 arranged on one side of the wall panel unit 1. The wall body The upper and lower ends of the module are respectively connected with the connectors to form a partition wall. The gaps between the adjacent wall panel units 1 and the gaps between the adjacent first wall panels 7 are alternately arranged. The two ends of the wall panel unit 1 are provided with useful For the card-horizontal keel connected to the adjacent wall panel unit 1, the card-horizontal keel is arranged along the height direction of the wall panel unit 1, and an empty area 3 is arranged on the wall body module. The empty area 3 includes an accommodation area 31 for accommodatin...

Embodiment 2

[0092] The embodiment of the present application provides a shielding plate, the shielding plate is installed on the opening area 32, the shielding plate includes a mounting part 81 and a limiting part 82, the mounting part 81 is installed into the opening area 32, and the limiting part 82 is against the opening area 32 wall panels at both ends.

[0093] The installation part 81 may be a square frame structure assembled from joists. Specifically, the left and right sides of the installation part 81 are card-horizontal keels, and the upper and lower sides are combined keels 9 with adjustable length; The C-shaped keel 91 (C73.5*50), by changing the length of the C-shaped keel 91 extending into the U-shaped keel 92, the length of the combined keel 9 is adjusted, so that the width of the installation part 81 is equal to the width of the opening area 32 adapt.

[0094] In actual use, the C-shaped keel 91 is slidably inserted into the U-shaped keel 92 to form the combined keel 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com