An intelligent detection system and method for automatic sensor abnormality

An intelligent detection and sensor technology, applied in the direction of test/monitoring control system, general control system, control/regulation system, etc., can solve the problems of high cost, less abnormal diagnosis of sensors, and uncontrollable flow combination, etc., to achieve high efficiency, Stable and reliable scalability to ensure the effect of safe and effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

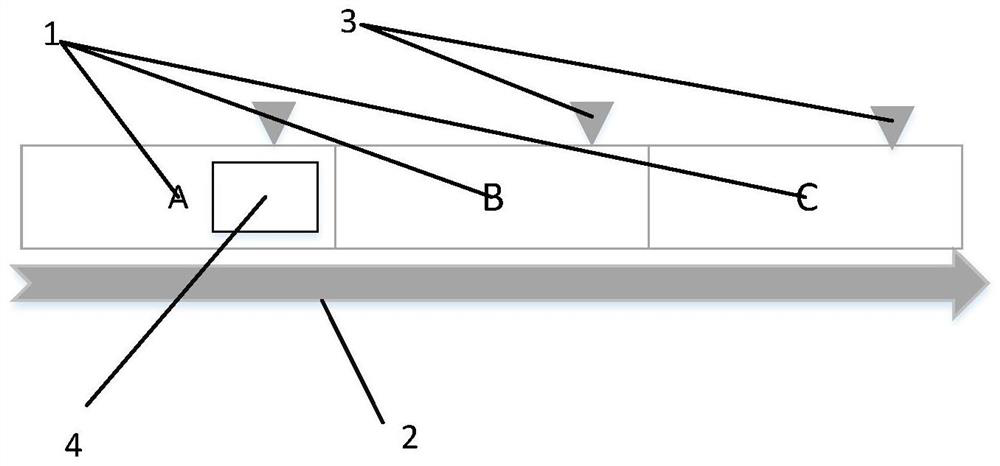

[0037] An intelligent detection system for automated sensor anomalies, including:

[0038] Feeding and conveying equipment, connected with the controller, used to receive signals from the controller to start and stop feeding materials;

[0039] Material receiving and conveying equipment, connected with the controller, used to receive signals from the controller to start and stop receiving materials;

[0040] Sensors, installed in the feeding and conveying equipment and receiving and conveying equipment, are used to obtain the current operating status of the equipment and feed back the logistics delivery direction of the equipment, information about the interconnection between equipment and equipment, operating status signals, information occupancy, and fault signals;

[0041] The controller, connected to each sensor and flashing alarm module, is used for abnormal detection based on the status information fed back by each sensor, diagnosing the operation of the equipment and th...

Embodiment 2

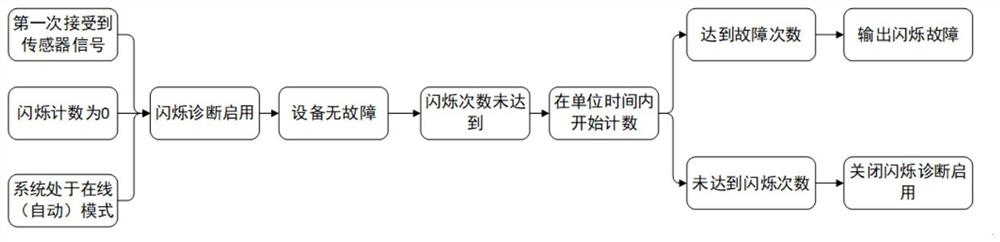

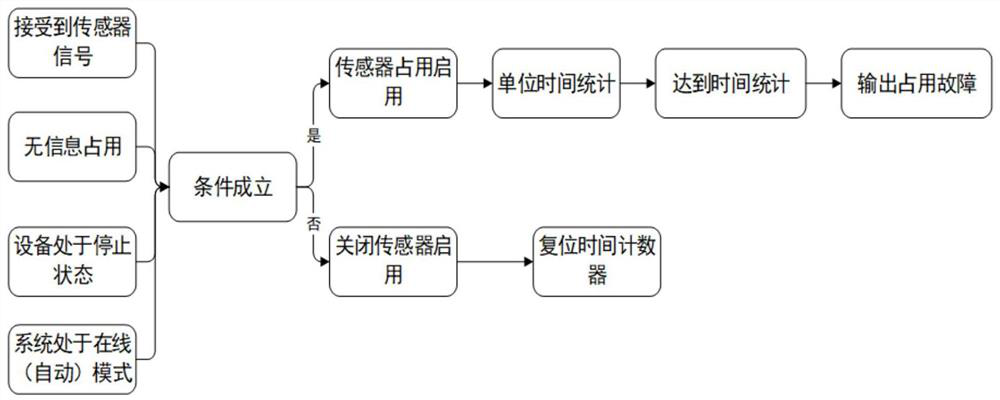

[0050] Embodiment 2: an intelligent detection method of an automatic sensor abnormality, comprising the following steps:

[0051] ① According to the equipment list of the automated logistics system project, define the sensor data mapping data table, diagnostic data table, status data table, etc. in the controller according to the equipment number;

[0052] ② Adjust the relevant sensor I / O to dark-on signal, and map it to the data mapping data table according to the function and sequence number;

[0053] ③ Integrate the status and signals of equipment operation feedback signals, information occupancy, fault signals, manual and automatic status into the status data table, and update them in real time;

[0054] ④Establish and assign IEC_TIMER data type timers: According to the equipment list of the project, establish and assign IEC_TIMER for each equipment according to the equipment number in the controller for equipment overtime alarm use;

[0055] ⑤Establish and distribute sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com