Dual channel cooling generator

A generator, dual-channel technology, applied in the field of dual-channel heat dissipation generators, can solve the problems of non-adjustable heat dissipation capacity, cold air interference, uneven heat dissipation, etc., to achieve uniform heat dissipation, adjustable heat dissipation capacity, and long service life of equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

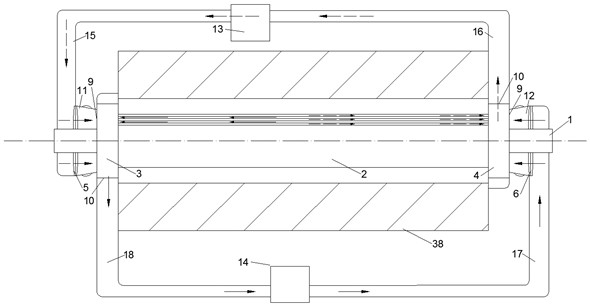

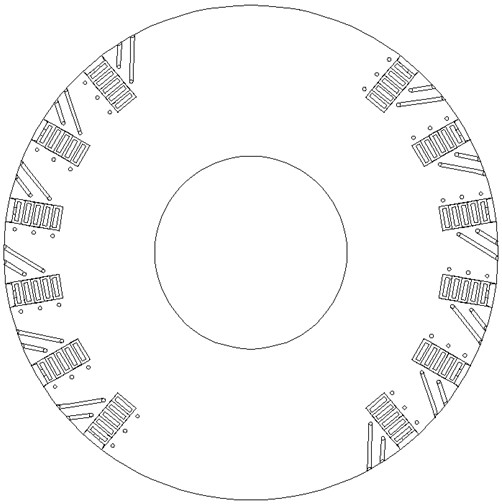

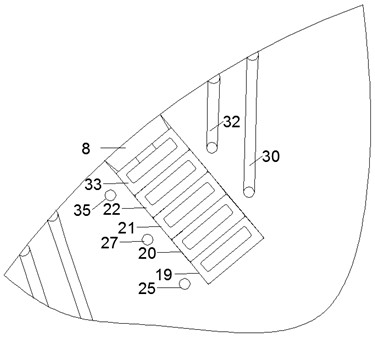

[0027] See attached Figure 1~7 . The dual-channel heat dissipation generator includes a rotating body; the rotating body includes a shaft body 1, an iron core body 2, a winding, a left fixed cover 3, a right fixed cover 4, a left fan 5 and a right fan 6; the shaft body 1 There is an iron core body 2, a left fan 5 and a right fan 6; the iron core body 2 is located between the left fan 5 and the right fan 6; The wire slot 7; the wire is wound on the wire slot 7 of the iron core body 2; the top of the wire slot 7 is provided with a slot stopper 8 for closing the wire slot 7; the left end of the iron core body 2 is covered with a left The fixed cover 3 has a right fixed cover 4 on the right end cover; the left fixed cover 3 and the right fixed cover 4 both include an air inlet end face 9 and an air outlet side 10; The end surface 9 is pressed into the wind flow, and pressed out from the air outlet side 10 of the right fixed cover 4; Side 10 is pressed out. It can be seen from...

Embodiment 2

[0029] See attached Figure 1~7 . The dual-channel heat dissipation generator includes a rotating body; the rotating body includes a shaft body 1, an iron core body 2, a winding, a left fixed cover 3, a right fixed cover 4, a left fan 5 and a right fan 6; the shaft body 1 There is an iron core body 2, a left fan 5 and a right fan 6; the iron core body 2 is located between the left fan 5 and the right fan 6; The wire slot 7; the wire is wound on the wire slot 7 of the iron core body 2; the top of the wire slot 7 is provided with a slot stopper 8 for closing the wire slot 7; the left end of the iron core body 2 is covered with a left The fixed cover 3 has a right fixed cover 4 on the right end cover; the left fixed cover 3 and the right fixed cover 4 both include an air inlet end face 9 and an air outlet side 10; The end surface 9 is pressed into the wind flow, and pressed out from the air outlet side 10 of the right fixed cover 4; Side 10 is pressed out. It can be seen from...

Embodiment 3

[0032] See attached Figure 1~7 . The dual-channel heat dissipation generator includes a rotating body; the rotating body includes a shaft body 1, an iron core body 2, a winding, a left fixed cover 3, a right fixed cover 4, a left fan 5 and a right fan 6; the shaft body 1 There is an iron core body 2, a left fan 5 and a right fan 6; the iron core body 2 is located between the left fan 5 and the right fan 6; The wire slot 7; the wire is wound on the wire slot 7 of the iron core body 2; the top of the wire slot 7 is provided with a slot stopper 8 for closing the wire slot 7; the left end of the iron core body 2 is covered with a left The fixed cover 3 has a right fixed cover 4 on the right end cover; the left fixed cover 3 and the right fixed cover 4 both include an air inlet end face 9 and an air outlet side 10; The end surface 9 is pressed into the wind flow, and pressed out from the air outlet side 10 of the right fixed cover 4; Side 10 is pressed out. It can be seen from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com