Industrial chemical experiment table

A technology for chemical experiments and test benches, used in laboratory stools/lab benches, laboratory utensils, chemical instruments and methods, etc., can solve the problems of inconvenient access and unstable center of gravity of chemical material bottles, and achieve uniform force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

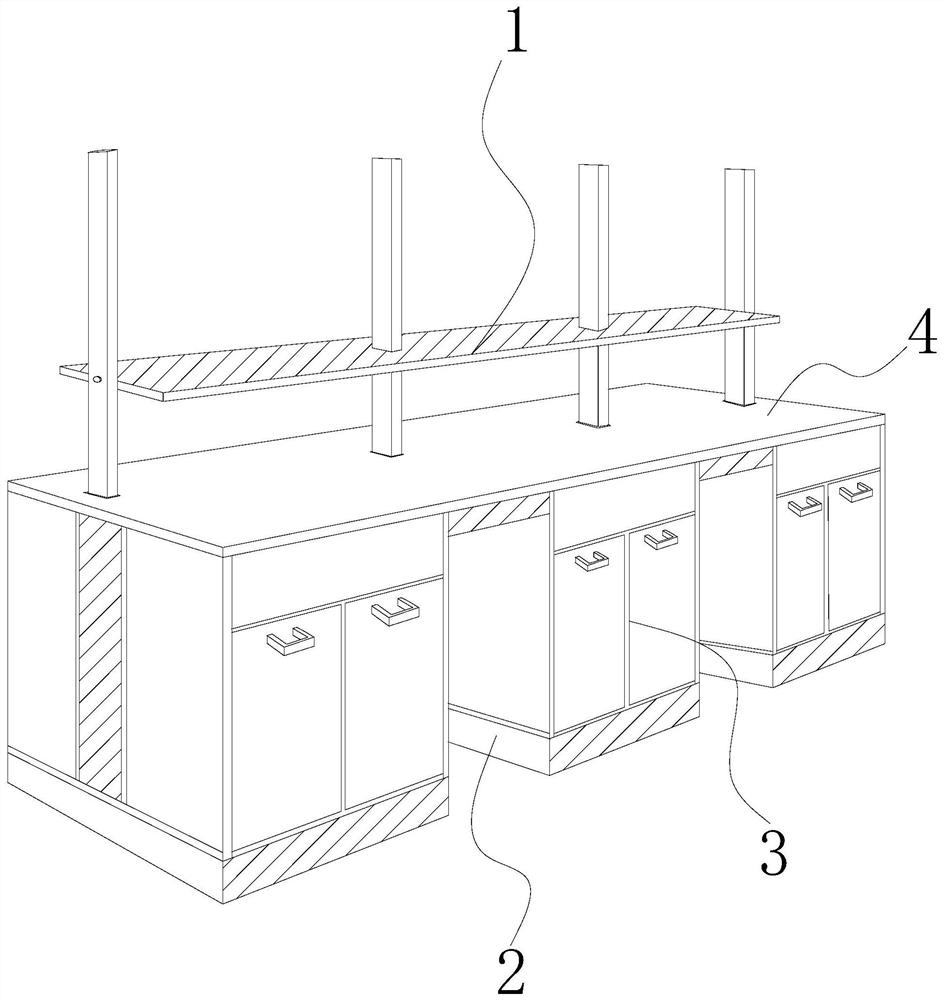

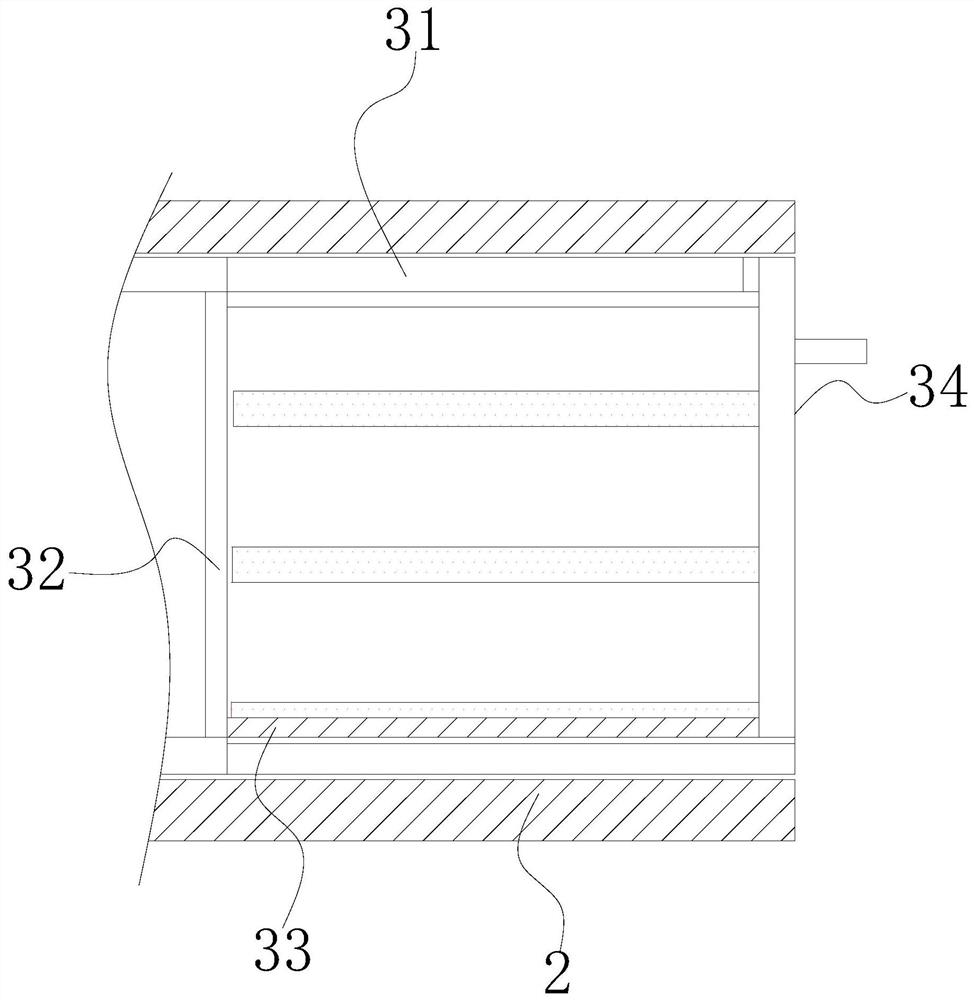

[0026] Such as Figure 1-Figure 5 Shown:

[0027] The present invention is an industrial chemical experiment platform, the structure of which includes a placement frame 1, a support platform 2, and a storage mechanism 3. The placement frame 1 is embedded in the upper end of the experiment platform 4, and the experiment platform 4 is attached to the upper end of the support platform 2. The storage mechanism 3 is installed inside the support platform 2, the storage mechanism 3 is provided with a fixed plate 31, a buffer plate 32, a sliding track 33, and a translation mechanism 34, and the buffer plate 32 is embedded in the fixed plate 31. The sliding track 33 is installed on the bottom side of the fixed plate 31, the lower end side of the translation mechanism 34 is in clearance fit with the sliding track 33, the fixed plate 31 is installed inside the support platform 2, and the right side of the buffer plate 32 is made of sponge material. It has the characteristics of strong c...

Embodiment 2

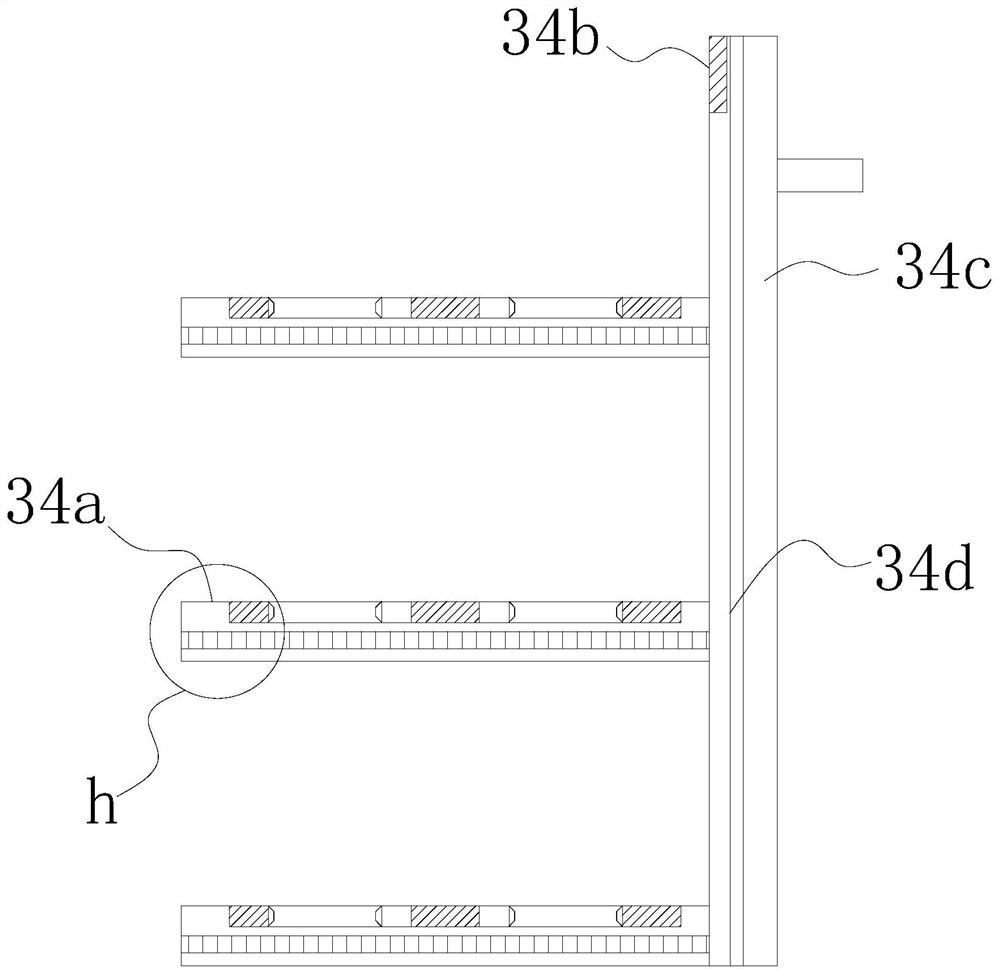

[0034] Such as Figure 6-Figure 8 Shown:

[0035] Wherein, the fixing mechanism 34a is provided with a friction plate a1, an engaging mechanism a2, and a sliding groove a3. The engaging mechanism a2 is embedded on the upper surface of the friction plate a1, and the sliding groove a3 is installed inside the friction plate a1. The right side of the friction plate a1 is embedded and fixed on the left side of the sliding mechanism 34d. The surface of the friction plate a1 is an inwardly sunken structure, which has the effect of fixing the chemical material and prevents the sliding mechanism 34d from causing the chemical material bottle to slide due to excessive inertial force when pushing. .

[0036]Wherein, the engaging mechanism a2 is provided with a compression plate a21, a bonding mechanism a22, and a curved plate a23, the curved plate a23 is bonded to the inside of the compression plate a21, and the curved plate a23 is welded to the inside of the bonding mechanism a22, so T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap