High-precision feeding work station for test/mark/test/tape machine and high-efficiency working method for high-precision feeding work station

A high-precision, consistent machine technology, applied in the direction of conveyors, conveyor objects, vibrating conveyors, etc., can solve problems such as long action cycles, and achieve the effect of simple and convenient limit and accurate and fast release of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

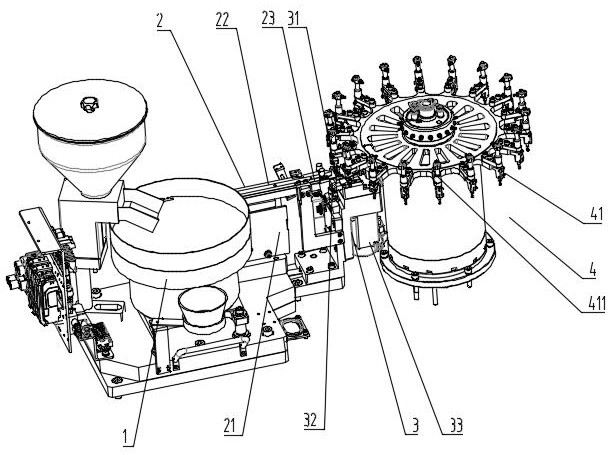

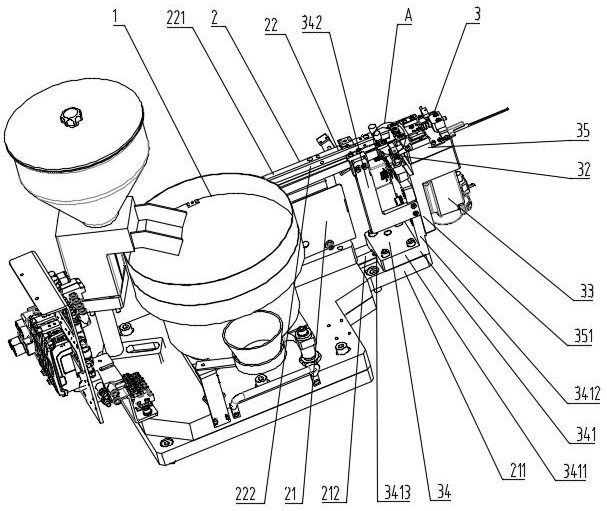

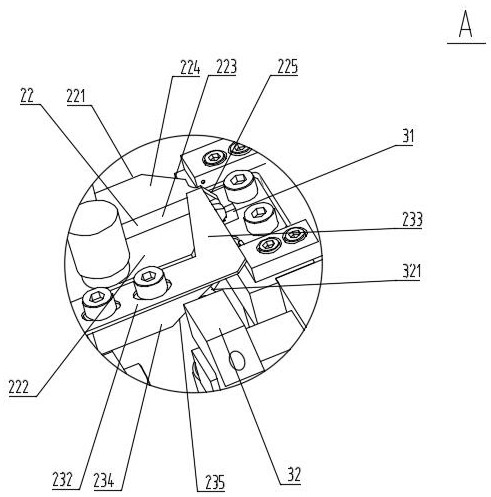

[0042] Please refer to figure 1 with figure 2 , the present invention provides a high-precision feeding station of an integrated machine, including a circular vibration component 1, a direct vibration component 2 and a separator component 3, the discharge port of the circular vibration component 1 and the material inlet of the direct vibration component 2 Connected, the feeding port of the direct vibration component 2 is docked with the separator component 3; the direct vibration component 2 includes a bracket 21 and a vibration tank 22, the vibration tank 22 is fixedly installed on the bracket 21, and the outlet of the vibration tank 22 is connected to the separator component 3 The outlet of the vibration groove 22 is provided with an elastic blocking structure 23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com