High-elasticity spiral artificial turf and preparation method thereof

An artificial turf, high elasticity technology, applied in textiles and papermaking, roads, pavements, etc., can solve the problems of curly wire consumption, harmful gases and particles, and limited application range, etc., achieve good elasticity and standing, enhance fiber rigidity, The effect of improving sports performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

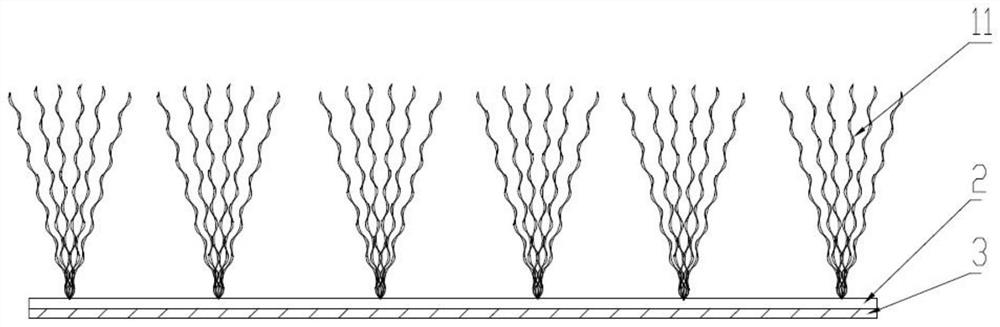

[0044]Example 1

[0045]Prepare high elastic artificial lawns as follows:

[0046](1) Preparing high-elastic spiral fibers

[0047]S1: Brushed: Mix the PE particles, color parent, UV aging master, etc., etc., put it to the equippedFigure 6The brigade of the medium (1) mold is carried out, producing the artificial grass yarn of DTEX 12000 / 6F, and outputs the yarn to the winding machine.

[0048]S2: Twisted: Import the above-mentioned artificial grass yarn yarn to the double twisting machine and twisting, the twist is 60 / meters;

[0049]S3: Heat Treatment: The above-mentioned 60-twisted artificial grasslet is placed in a 98 ° C vapor hot water tank, and then naturally drying cooling 72h, obtaining a spiral fiber having a spring appearance.

[0050](2) Preparation of high-elastic artificial turf

[0051]S4: Tufted: The above-mentioned highly elastic spiral fibers are 50 mm, 5 / 8 inch, 160-meter specification tufts on a low shrinkage woven fabric;

[0052]S5: Adhesive: Apply a layer of butyrene latex to the...

Example Embodiment

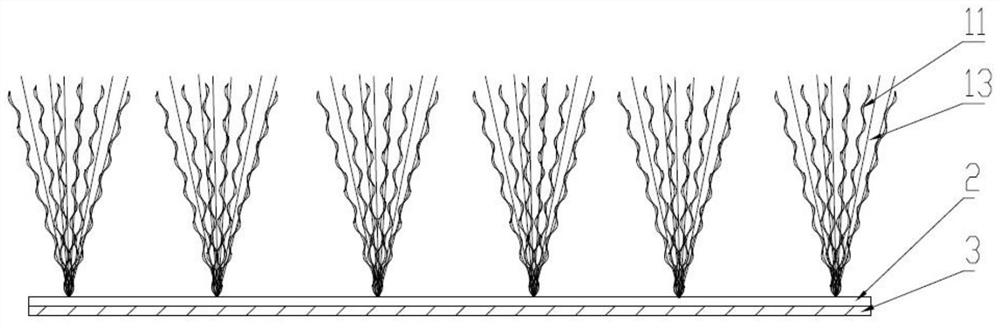

[0053]Example 2

[0054]Prepare high elastic artificial lawns as follows:

[0055](1) Preparing high-elastic spiral fibers

[0056]S1: Brushed: Mix the PE particles, color parent, UV aging master, etc., etc., put it to the equippedFigure 6The brigade of the medium (1) mold is carried out, producing the artificial grass yarn of DTEX 12000 / 6F, and outputs the yarn to the winding machine.

[0057]S2: Twisted: Import the above-mentioned artificial grass yarn yarn to the double twisting machine and twisting, the twist is 60 / meters;

[0058]S3: Heat Treatment: The above-mentioned 30-twisted artificial grass yarn is placed in a 100 ° C hot air oven, then naturally cooled 24 h, which obtained a spiral fiber having a spring appearance.

[0059](2) Preparation of high-elastic artificial turf

[0060]S4: Tufted: The above-mentioned highly elastic spiral fibers are 50 mm, 5 / 8 inch, 160-meter specification tufts on a low shrinkage woven fabric;

[0061]S5: Adhesive: Applying a polyurethane adhesive on the back of t...

Example Embodiment

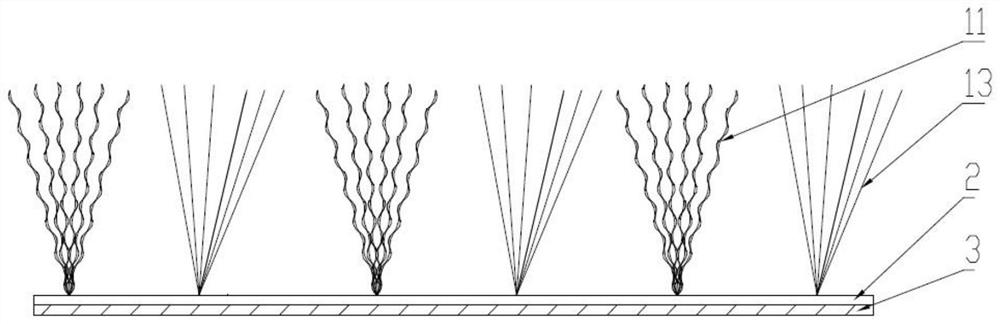

[0062]Example 3

[0063]Prepare high elastic artificial lawns as follows:

[0064](1) Preparing high-elastic spiral fibers

[0065]S1: Brushed: Mix the PE particles, color parent, UV aging master, etc., etc., put it to the equippedFigure 6The brigade of the medium (1) mold is carried out, producing the artificial grass yarn of DTEX 12000 / 6F, and outputs the yarn to the winding machine.

[0066]S2: Twisted: Import the above-mentioned artificial grass yarn yarn to the double twisting machine and twisting, the twist is 60 / meters;

[0067]S3: Heat Treatment: The above-mentioned 60-twisted artificial grass yarn passes through the pressure roller of the 5M steam hot water tank, so that the yarn is completely immersed in the water, wherein the hot tank temperature is controlled at 98 ° C, and the transmission roller speed is 75m / MIN, keep the yarn tight, use the air-cooled tank after the water tank, remove excess water, and then reward the spiral fibers having a spring appearance;

[0068](2) Preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com