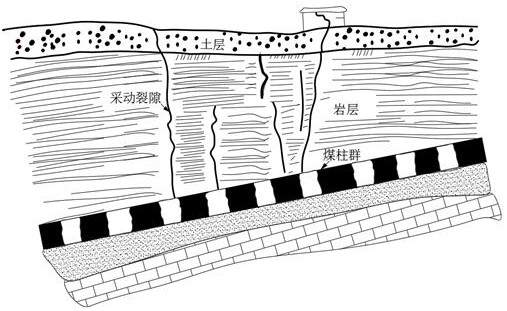

Device and method for testing bearing capacity of multiple rows of group columns under uniaxial loading in inclined goaf

A test device and goaf technology, which is applied in the test of basic structure, construction, basic structure engineering, etc., can solve the problem that the overall bearing capacity of the stope group column is difficult to realize, and it is impossible to study the single bearing capacity of the group column system under variable angles , Unable to load the sample of the group column, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

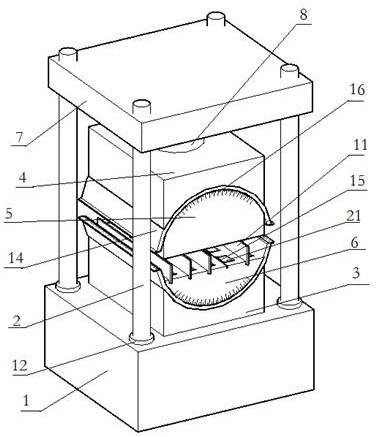

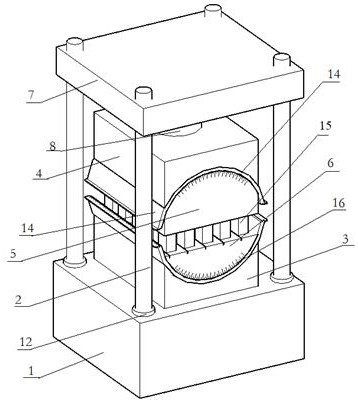

[0043] Such as Figure 1-11 As shown, a test device for the bearing capacity of multi-row column groups under uniaxial loading in inclined gobs includes: a testing machine base 1, a frame 2, a lower pressure plate 3, an upper pressure plate 4, an upper sliding deck 5, a lower Sliding deck 6, horizontal frame 7, hydraulic push shaft 8, hydraulic cylinder 9, pressure sensor 10, baffle plate 11, protective ring 12, push shaft shell 13, fixed ring 14, scale line 16, fixing bolt 17, arc clamp Block 18, fixed roller 19, arc groove 20, positioning groove 21, fixed block 22.

[0044] The base 1 is provided with four protective rings 12 , each protective ring 12 is equipped with a frame 2 , one end of the frame 2 is connected with the base 1 , and the other end is connected with the horizontal frame 7 . The force control device includes a hydraulic propulsion shaft 8, a hydraulic cylinder 9, and a pressure sensor 10; the hydraulic propulsion shaft 8 is controlled and regulated by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com